Lógica del zócalo de fuente de alimentación rusa FAW: La puerta de entrada al acceso constante a la energía de 24 V en condiciones árticas

El Toma de corriente rusa FAW assembly is the dedicated interface for high-demand auxiliary electrical equipment within the CA3250P66K24L1TE5Z dump truck. Distinct from the standard cigarette lighter, this unit is engineered to provide a stable, high-amperage 24V connection for professional tools, inverters, and heavy-duty cabin accessories. In the isolated environments of the Russian North, where drivers often live and work out of their cabs for days, la confiabilidad del Toma de corriente rusa FAW is essential for maintaining communication, warmth, and operational capability.

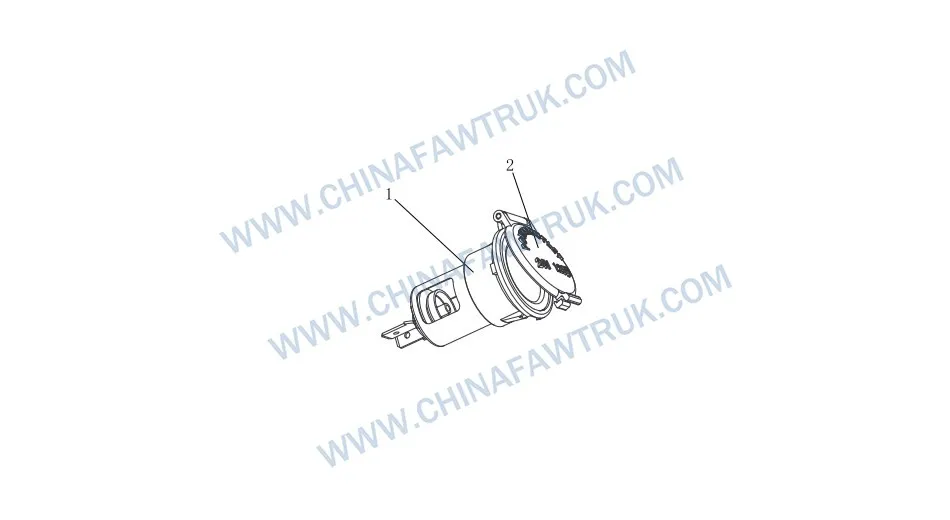

Toma de corriente rusa FAW

| No. |

Número de pieza |

Nombre de la pieza |

Cantidad |

| 1 | 3736050-828 | 24V Conjunto de enchufe de la fuente de alimentación | 1 |

| 2 | 3736055-828 | 24V Power Supply Socket Cover Assembly | 1 |

Dedicated Power Delivery Architecture

El Toma de corriente rusa FAW is designed to fulfill a specific role that differentiates it from standard lighter sockets. While cigarette lighters are designed for short bursts of intense heat, el 24V Conjunto de enchufe de la fuente de alimentación (Número de pieza. 3736050-828) is engineered for continuous power delivery. La geometría interna del Toma de corriente rusa FAW is deeper and features stronger retention clips to hold heavy plugs securely in place, preventing the intermittent connection issues that can damage sensitive electronics like GPS units or on-board diagnostic tools.

El “828” specification suffix in the part number indicates a heavy-duty construction tailored for the commercial vehicle market. El cuerpo del Toma de corriente rusa FAW uses a thermoset plastic capable of withstanding the heat generated by long-term high-current draw without deformation. This is crucial when powering devices such as portable fridges or electric lunch boxes, which may draw 5-10 amps continuously for hours. El Toma de corriente rusa FAW ensures that this load is handled safely, without the risk of the socket melting or the contacts annealing.

Electrically, el Toma de corriente rusa FAW is wired with a heavier gauge harness than standard cabin accessories. It typically bypasses the ignition switch’s accessory position, often being wired directly to a dedicated 20A or 30A circuit in the fuse box. Esto permite que el Toma de corriente rusa FAW to provide stable voltage with minimal drop, ensuring that connected devices receive the clean power they need to operate efficiently, which is particularly important for charging cordless tool batteries on the go.

Environmental Protection and Safety

Una característica clave del Toma de corriente rusa FAW sistema es el 24V Power Supply Socket Cover Assembly (Número de pieza. 3736055-828). In the dusty environment of a mine or quarry, an open socket is a magnet for conductive debris. Coal dust or metallic filings entering the socket can cause a direct short circuit. The cover assembly on the Toma de corriente rusa FAW is spring-loaded to snap shut automatically when a plug is removed, providing an immediate barrier against contamination.

The material of the cover is a soft-touch, impact-resistant polymer that retains flexibility in extreme cold. Hard plastics often snap off at the hinge point when manipulated in -40°C cabin temperatures. El Toma de corriente rusa FAW cover is designed to withstand thousands of open-close cycles without fatigue. This simple component is vital for the long-term reliability of the Toma de corriente rusa FAW, ensuring that the internal contacts remain clean and free of oxidation.

Safety is further enhanced by the non-conductive nature of the socket’s inner lining. Unlike older metal-lined sockets, el Toma de corriente rusa FAW insulates the positive terminal deep within the housing. This prevents accidental shorts caused by coins or keys falling into the socket. El diseño de la Toma de corriente rusa FAW prioritizes operator safety, reducing the risk of cabin fires caused by debris bridging the contacts.

Installation and Serviceability

El Toma de corriente rusa FAW is designed for ease of installation and replacement. The assembly typically mounts into a standard DIN-sized cutout or a specific dashboard bezel using integrated friction tabs. This tool-free mounting allows for rapid assembly on the production line and simplifies replacement in the field. If a Toma de corriente rusa FAW falla, it can be popped out from behind the dash panel without the need to remove extensive trim pieces.

The electrical interface on the back of the Toma de corriente rusa FAW uses standard spade terminals, usually arranged in a ‘T’ configuration to prevent reverse polarity connection. This standardization allows fleet mechanics to easily test the circuit with a multimeter. Al dar servicio al Toma de corriente rusa FAW, it is important to check the condition of the female spade connectors on the wiring harness. Loose connectors are a common cause of heat buildup and socket failure.

El 24V Power Supply Socket Cover Assembly is often a separate serviceable part that snaps onto the main socket body. This modularity means that if a driver accidentally breaks the cover, todo el Toma de corriente rusa FAW does not necessarily need to be replaced. This thoughtful design reduces maintenance costs and waste, aligning with the practical needs of fleet operations where minor cabin damage is common.

Mejores prácticas operativas

To maximize the lifespan of the Toma de corriente rusa FAW, operators should be trained on its limitations. While it is a robust unit, it is not designed to support heavy inverters directly; devices drawing more than 15-20 amps should be hardwired to the battery. Overloading the Toma de corriente rusa FAW can anneal the internal spring contacts, causing them to lose their grip strength. A loose socket causes arcing, which pits the contacts and eventually leads to total failure.

Regular cleaning of the Toma de corriente rusa FAW is also recommended. A quick blast of compressed air can remove dust and lint that accumulates at the bottom of the well. Sin embargo, conductive cleaners or water should never be sprayed into the socket. si el Toma de corriente rusa FAW shows signs of internal rust or green copper corrosion, immediate replacement is the only safe option to prevent potential electrical faults.

Utilizar piezas originales FAW para el Toma de corriente rusa FAW ensures compatibility with the vehicle’s 24V system. Many aftermarket sockets are rated only for 12V and use thinner plastic walls that can melt under 24V loads. el genuino Toma de corriente rusa FAW is tested to meet the specific flammability and electrical standards required for commercial vehicles, providing peace of mind for the fleet manager.

Conclusión: Essential Connectivity

El Toma de corriente rusa FAW logic assembly is a deceptively simple yet critical component of the driver’s environment. Comprising the main socket and its protective cover, this unit enables the use of modern technology and comfort accessories in the remote wilderness. Its rugged construction and thoughtful design ensure that power is always available when needed.

Para operadores de flotas, maintaining the functionality of the Toma de corriente rusa FAW is a low-cost way to improve driver satisfaction and operational efficiency. By ensuring these outlets are working and structurally sound, fleets support the diverse needs of their drivers, from charging communication devices to powering meal heaters, keeping the human element of the machine functioning at peak performance.

Embalaje y Logística

piezas FAW, incluido el conjunto del bloque de cilindros, Se empaquetan con cuidado para garantizar una entrega segura.. Cada componente está asegurado con materiales protectores para evitar daños durante el transporte.. La red logística garantiza envíos puntuales en todo el mundo., apoyando operaciones de mantenimiento eficientes. A continuación se muestra una imagen que ilustra el embalaje estándar de las piezas de camiones FAW., mostrando la atención al detalle en el manejo y almacenamiento.

Este enfoque de embalaje minimiza el riesgo de corrosión o daños por impacto., asegurando que piezas como el conjunto de bloque de cilindros FAW lleguen en perfectas condiciones. Los clientes pueden confiar en la logística de FAW para obtener calidad y confiabilidad constantes.