FAW مجموعة الحاجز العلوي الروسي: هيكلة 15 طبقات دفاعية ضد حطام الطريق في القطب الشمالي

ال FAW الحاجز العلوي الروسي assembly is the primary shield for the cabin and chassis of the CA3250P66K24L1TE5Z dump truck. In the brutal environment of the Russian Federation, where haul roads are a mixture of frozen mud, sharp gravel, and corrosive de-icing salts, ال FAW الحاجز العلوي الروسي serves as the first line of defense. This multi-part assembly not only prevents debris from impacting the cab paintwork but also integrates the driver’s entry steps, combining structural utility with protective function. Engineered with impact-resistant polymers and heavy-duty steel brackets, ال FAW الحاجز العلوي الروسي is built to withstand the continuous bombardment of heavy-duty mining operations while maintaining the vehicle’s aerodynamic profile.

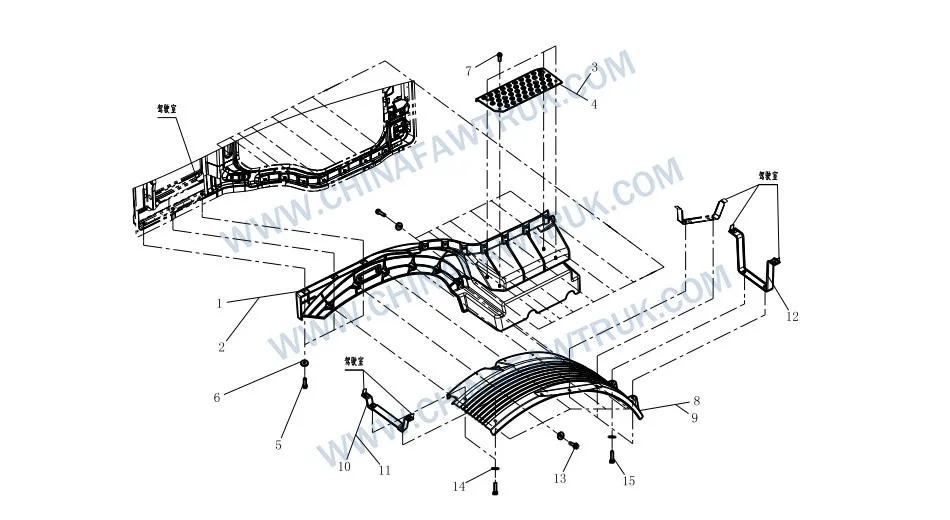

FAW الحاجز العلوي الروسي

| لا. |

رقم الجزء |

جزء اسم |

الكمية |

| 1 | 5103121-B35 | الحاجز العلوي الأيسر | 1 |

| 2 | 5103122-B35 | الحاجز العلوي الأيمن | 1 |

| 3 | 5103191BA01 | لوحة الخطوة اليسرى من المستوى الثالث | 1 |

| 4 | 5103192BA01 | لوحة الخطوة اليمنى من المستوى الثالث | 1 |

| 5 | CQ1420625F6 | تركيبة الترباس | 20 |

| 6 | Q40206F6 | غسالة كبيرة | 20 |

| 7 | Q2360612F6 | مجموعة براغي وغسالة ذات رأس مجوف متقاطع | 8 |

| 8 | 5103161-B35 | واقي الطين العلوي الأيسر | 1 |

| 9 | 5103162-B35 | واقي الطين العلوي الأيمن | 1 |

| 10 | 5103145-B35 | مجموعة الدعامة الخلفية لواقيات الطين العلوية اليسرى | 1 |

| 11 | 5103150-B35 | مجموعة الدعامة الخلفية لواقيات الطين العلوية اليمنى | 1 |

| 12 | 5103140-أ01 | مجموعة الدعامة الأمامية لواقي الطين العلوي | 2 |

| 13 | CQ1460616 | تركيبة الترباس | 12 |

| 14 | Q40206 | غسالة كبيرة | 24 |

| 15 | CQ1420620 | تركيبة الترباس | 12 |

Modular Panel Architecture

ال FAW الحاجز العلوي الروسي assembly is constructed from distinct modular panels, allowing for segmented replacement in the event of impact damage—a frequent occurrence on narrow mining roads. The primary aerodynamic surface is provided by the الحاجز العلوي الأيسر (الجزء لا. 5103121-B35) و الحاجز العلوي الأيمن (الجزء لا. 5103122-B35). These panels are molded from a high-impact thermoplastic polyolefin (TPO) that retains flexibility at sub-zero temperatures. Unlike rigid fiberglass, which shatters upon impact with frozen berms, ال FAW الحاجز العلوي الروسي material absorbs energy, resisting cracks and preserving the cabin’s aesthetic and aerodynamic lines.

Below the main fender lies the واقي الطين العلوي الأيسر (الجزء لا. 5103161-B35) و واقي الطين العلوي الأيمن (الجزء لا. 5103162-B35). These components act as the inner shield, preventing mud and slurry thrown by the tires from packing into the door hinges and step wells. في FAW الحاجز العلوي الروسي تصميم, these mudguards are detachable, facilitating easy access to the engine bay or suspension components during major service intervals without removing the entire fender assembly.

The assembly also integrates the driver’s access system via the لوحة الخطوة اليسرى من المستوى الثالث (الجزء لا. 5103191BA01). This step plate is not merely bolted on; it is structurally integrated into the fender support system to bear the weight of a driver wearing heavy winter gear. The surface of the step within the FAW الحاجز العلوي الروسي features an aggressive anti-slip tread pattern, essential for safety when the truck is coated in ice and snow.

Bracketry and Structural Support

Behind the plastic skin of the FAW الحاجز العلوي الروسي lies a robust skeleton of steel brackets. ال مجموعة الدعامة الأمامية لواقي الطين العلوي (الجزء لا. 5103140-أ01) provides the forward anchor point, connecting the fender to the cab structure. This bracket is designed to flex slightly, decoupling the fender from the high-frequency vibrations of the cab mount. Without this compliance, the rigid plastic fender would eventually fatigue and crack at the mounting points.

The rear section is supported by the مجموعة الدعامة الخلفية لواقيات الطين العلوية اليسرى (الجزء لا. 5103145-B35) and its right-hand counterpart. These brackets are particularly substantial as they must support the cantilevered weight of the mudguard and any accumulated mud or ice load, which can add tens of kilograms in winter conditions. ال FAW الحاجز العلوي الروسي brackets are e-coated or galvanized to resist the intense corrosion found in the wheel arch environment, ensuring they do not rust failure before the vehicle’s service life ends.

The alignment of these brackets is critical for the fit and finish of the FAW الحاجز العلوي الروسي. Slotted mounting holes allow for fine-tuning of the panel gaps, ensuring that the door seal remains effective and wind noise is minimized. This adjustability is a key feature of the FAW design, accommodating the manufacturing tolerances of the cab welding assembly.

ربط المنطق والتحكم في الاهتزاز

تأمين FAW الحاجز العلوي الروسي requires a fastening strategy that distributes load and prevents loosening. The assembly uses a multitude of تركيبة الترباس السحابات (جزء رقم. CQ1420625F6, CQ1460616, CQ1420620). These bolts feature integrated captive washers that prevent the bolt head from digging into the soft plastic of the fender panels. استخدام “براغي الجمع” speeds up assembly and ensures that a washer is never forgotten, which is critical for maintaining the clamping force on the FAW الحاجز العلوي الروسي متأخر , بعد فوات الوقت.

To further protect the plastic panels, the installation includes غسالة كبيرة (جزء رقم. Q40206F6 و Q40206). These wide-diameter washers spread the fastening load over a large area, reducing stress concentrations that could lead to stress whitening or cracking around the bolt holes. في FAW الحاجز العلوي الروسي طلب, these washers are essential for maintaining the integrity of the panel mounting points, especially when the plastic becomes brittle in extreme cold.

استخدام مجموعة براغي وغسالة ذات رأس مجوف متقاطع (الجزء لا. Q2360612F6) is reserved for lower-stress areas or trim attachments. ال “F6” designation on many of these fasteners indicates a high-grade corrosion-resistant coating, typically a zinc-flake or similar treatment. وهذا يضمن أن FAW الحاجز العلوي الروسي can be disassembled for service even after years of exposure to corrosive road salts, preventing the fasteners from seizing in place.

Maintenance and Replacement Strategy

ال FAW الحاجز العلوي الروسي is designed as a sacrificial component; its job is to take the hits so the metal cab doesn’t have to. Fleet operators should regularly inspect the fender panels for cracks or loose fasteners. A flapping fender can quickly fatigue its mounting brackets or rub through the paint on the cab door, مما يؤدي إلى الصدأ. Tightening the تركيبة الترباس fasteners should be part of the routine chassis lubrication service.

When replacing a damaged الحاجز العلوي الأيسر أو الحاجز العلوي الأيمن, it is crucial to transfer all the metal clips and speed nuts from the old panel if the new one does not come equipped with them. Using the correct غسالة كبيرة hardware is non-negotiable; substituting standard washers will lead to the new panel cracking within weeks of installation due to point-loading.

ل Third-Level Step Plate, inspection for impact damage is vital for driver safety. A bent step bracket can be a slip hazard. منذ FAW الحاجز العلوي الروسي integrates this step, damage to the step often requires replacing or reinforcing the fender support structure. Using genuine FAW parts ensures that the step geometry matches the cab entry layout, maintaining ergonomic safety standards.

خاتمة: درع القطب الشمالي

ال FAW الحاجز العلوي الروسي assembly is more than just a mudflap; it is a sophisticated system of 15 distinct components working together to protect the truck and the driver. From the impact-resistant polymer skins to the heavy-duty steel brackets and specialized fasteners, every part is engineered to survive the unique challenges of the Russian heavy transport sector.

لمديري الأسطول, الحفاظ على FAW الحاجز العلوي الروسي is essential for preserving the vehicle’s value and safety. A well-maintained fender system keeps the cab clean, protects the door mechanisms, and provides safe access for the driver. By using genuine parts and adhering to proper fastening procedures, يضمن المشغلون أن يظل أسطولهم محترفًا, وظيفية, and ready for the road.

التعبئة والتغليف والخدمات اللوجستية

أجزاء فاو, بما في ذلك مجموعة كتلة الأسطوانة, يتم تعبئتها بعناية لضمان الولادة الآمنة. يتم تأمين كل مكون في مواد واقية لمنع الضرر أثناء النقل. تضمن الشبكة اللوجستية الشحنات في الوقت المناسب في جميع أنحاء العالم, دعم عمليات الصيانة الفعالة. فيما يلي صورة توضح العبوة القياسية لقطع غيار شاحنات FAW, إظهار الاهتمام بالتفاصيل في التعامل والتخزين.

يقلل أسلوب التغليف هذا من مخاطر التآكل أو التلف الناتج عن الصدمات, ضمان وصول أجزاء مثل FAW Cylinder Block Assembly في حالة ممتازة. يمكن للعملاء الاعتماد على الخدمات اللوجستية التي تقدمها FAW للحصول على الجودة والموثوقية المتسقة.