FAW الروسية توقيت والعتاد المنطق: 16 مكونات دقيقة لتزامن لا مثيل له

ال FAW الروسية توقيت والعتاد المنطق is the symphonic conductor of the CA3250P66K24L1TE5Z engine, ensuring absolute synchronization between piston movement, valve actuation, and fuel injection. في المناخ الذي لا يرحم في الاتحاد الروسي, this all-gear drive system provides superior reliability compared to belts or chains, resisting stretching and breakage at -40°C. This guide breaks down the complex gear train into its constituent shafts, idlers, and fasteners for precise maintenance.

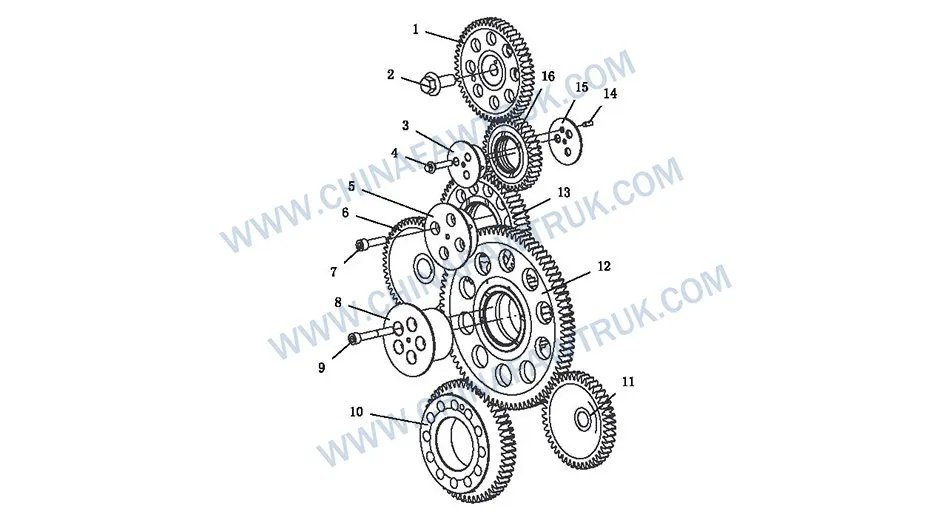

FAW الروسية توقيت والعتاد المنطق

Master and Slave: Crankshaft and Camshaft Synchronization

At the foundation of the FAW الروسية توقيت والعتاد المنطق يكمن Crankshaft Timing Gear (الجزء لا. 1005037-81د). This primary drive gear is shrink-fitted onto the crankshaft nose, converting linear piston motion into rotational timing data. Its helical tooth profile is precision-ground to minimize gear whine and maximize contact area, ensuring that the immense torque required to drive the entire valvetrain is transferred without slippage or tooth deformation under heavy load.

The recipient of this rotational force is the Camshaft Timing Gear (الجزء لا. 1006021-81د). Located at the top of the gear train, it spins at exactly half the speed of the crankshaft to manage the four-stroke combustion cycle. The engagement between these gears within the FAW الروسية توقيت والعتاد المنطق must remain backlash-free to prevent “timing scatter,” which can cause erratic idling and reduced power in cold conditions where fuel atomization is already compromised.

Securing this critical upper gear is the specialized Fastening Bolt – Camshaft Timing Gear (الجزء لا. 1006017-53د). هذا ليس قفل قياسي; it is a high-tensile bolt designed to resist the cyclical shear loads generated by the valve springs compressing and releasing. If this bolt were to loosen, ال FAW الروسية توقيت والعتاد المنطق would fail instantly, likely resulting in catastrophic valve-to-piston contact that would destroy the engine.

علم المواد وراء FAW الروسية توقيت والعتاد المنطق involves case-hardened steel alloys. These materials are chosen specifically for their ability to resist surface pitting and spalling. في القطب الشمالي الروسي, lubrication can be delayed during startup; these hardened surfaces ensure the gears can survive momentary boundary lubrication conditions without sustaining permanent damage.

The Idler Network: Stack Gears and Shafts

Bridging the gap between the crank and cam is a complex network of idler gears, بدءا من Timing Intermediate Stack Gear Assembly (الجزء لا. 1006040-81د). هذا “كومة” gear is a compound unit, often featuring two gear faces to effect a gear reduction or to drive multiple accessories simultaneously. ال FAW الروسية توقيت والعتاد المنطق relies on this component to distribute rotational force to the injection pump and air compressor without overloading a single gear mesh.

Supporting these rotating masses are specialized shafts, مثل Timing Intermediate Gear Shaft (أنا) (الجزء لا. 1006051-81د) و Timing Intermediate Gear Shaft (ثالثا) (الجزء لا. 1006057-81د). These shafts act as stationary axles upon which the gears rotate, typically riding on pressure-fed bushings. The rigidity of these shafts is paramount; any deflection would misalign the gear teeth, leading to rapid wear and noise within the FAW الروسية توقيت والعتاد المنطق نظام.

Further along the train, we find the Timing Intermediate Gear (ثانيا) (الجزء لا. 1006053-81د) و Timing Intermediate Gear Assembly (الجزء لا. 1006060-81د). These gears transmit motion laterally across the engine front. دقة ال FAW الروسية توقيت والعتاد المنطق ensures that the backlash (the clearance between mating teeth) is kept within microscopic tolerances, منع “clattering” noise often associated with older diesel engines.

Axial movement of these gears is controlled by components like the Timing Intermediate Gear (ثالثا) Thrust Plate (الجزء لا. 1006056-81د). This hardened steel plate prevents the gear from “المشي” off its shaft under the influence of helical gear thrust forces. في FAW الروسية توقيت والعتاد المنطق, maintaining axial position is as critical as radial alignment to prevent the gears from machining into the timing cover.

Fuel and Air: Driving Critical Accessories

ال FAW الروسية توقيت والعتاد المنطق is responsible for more than just valve events; it powers the engine’s life support systems. ال ترس تشغيل مضخة حقن الوقود (الجزء لا. 1111216-81د) is perhaps the most critical auxiliary component. It drives the high-pressure fuel pump, timing the injection of diesel fuel to the microsecond. A failure or slip here would result in immediate engine shutdown or severe knock.

معًا, ال Air Compressor Driven Gear (الجزء لا. 1006047-81د) powers the pneumatic system for the truck’s brakes and suspension. في سياق FAW الروسية توقيت والعتاد المنطق, this gear must withstand the high pulsating loads of the reciprocating air compressor. The robust tooth profile ensures that braking air pressure is built rapidly, even when the engine is idling in cold weather.

The integration of these accessories directly into the gear train, rather than using belts, is a hallmark of the FAW الروسية توقيت والعتاد المنطق تصميم. Belts can become brittle and snap in -50°C temperatures, whereas steel gears provide fail-safe operation. This direct-drive architecture is a key selling point for reliability in the Russian logistics sector.

Alignment of these accessory gears is finalized by the دبوس أسطواني (الجزء لا. س5210616). This dowel pin ensures that the accessory housings are perfectly centered relative to the gear train. Any misalignment in the FAW الروسية توقيت والعتاد المنطق auxiliary drive would place excessive side loads on the pump bearings, leading to premature seal failure and leaks.

The Anchors: High-Strength Fastening Strategy

سلامة FAW الروسية توقيت والعتاد المنطق is held together by a specific selection of fasteners. يستخدم التجمع سداسي مقبس رأس غطاء رأس (الجزء لا. CQ2181040TF2 and CQ2181070TF2) for precision clamping. These socket head screws allow for high torque application in tight spaces where a standard hex wrench cannot fit, ensuring the gear shafts are locked solidly to the block.

For larger structural components, ال مسدس شفة الترباس (الجزء لا. س1840840) يتم استخدامه. The flange design distributes the clamping load over a wider area, preventing the bolt head from digging into the gear hubs or thrust plates. في FAW الروسية توقيت والعتاد المنطق, maintaining consistent clamping force is vital to prevent fretting corrosion between mating surfaces.

These fasteners are treated with anti-corrosion coatings to survive the harsh environment inside the engine, where acidic oil byproducts can attack standard steel. بالإضافة إلى, ال FAW الروسية توقيت والعتاد المنطق assembly often requires the use of thread-locking compounds on these bolts to prevent them from backing out under the intense high-frequency vibration of the gear train.

قائمة تفصيل المكونات

يسرد الجدول التالي التقسيم الكامل لل FAW الروسية توقيت والعتاد المنطق حَشد. Precision in part selection is required during overhauls to maintain the intricate timing relationships of the CA3250P66K24L1TE5Z engine.

| لا. |

رقم الجزء |

جزء اسم |

الكمية |

| 1 |

1006021-81د |

Camshaft Timing Gear |

1 |

| 2 |

1006017-53د |

Fastening Bolt – Camshaft Timing Gear |

1 |

| 3 |

1006057-81د |

Timing Intermediate Gear Shaft (ثالثا) |

1 |

| 4 |

س1840840 |

مسدس شفة الترباس (Coarse/Standard) |

3 |

| 5 |

1006053-81د |

Timing Intermediate Gear (ثانيا) |

1 |

| 6 |

1111216-81د |

ترس تشغيل مضخة حقن الوقود |

1 |

| 7 |

CQ2181040TF2 |

سداسي مقبس رأس غطاء رأس |

4 |

| 8 |

1006051-81د |

Timing Intermediate Gear Shaft (أنا) |

1 |

| 9 |

CQ2181070TF2 |

سداسي مقبس رأس غطاء رأس |

5 |

| 10 |

1005037-81د |

Crankshaft Timing Gear |

1 |

| 11 |

1006047-81د |

Air Compressor Driven Gear |

1 |

| 12 |

1006040-81د |

Timing Intermediate Stack Gear Assembly |

1 |

| 13 |

1006060-81د |

Timing Intermediate Gear Assembly |

1 |

| 14 |

س5210616 |

دبوس أسطواني |

1 |

| 15 |

1006056-81د |

Timing Intermediate Gear (ثالثا) Thrust Plate |

1 |

| 16 |

1006070-81د |

Timing Intermediate Gear Assembly |

1 |

Critical Diagnostics for Gear Train Health

الحفاظ على FAW الروسية توقيت والعتاد المنطق يبدأ بالتشخيص السمعي. A whining sound that increases with RPM often indicates worn teeth or excessive backlash in the Timing Intermediate Gear شبكة. This wear exposes the engine to timing drift, which manifests as rough idling and increased fuel consumption. Mechanics should use a stethoscope on the front timing cover to isolate the noise source before teardown.

Visual inspection is possible during major service intervals. تحقق من Timing Intermediate Gear Shaft surfaces for scoring or blueing, which indicates overheating due to oil starvation. In the cold Russian climate, ensuring that the oil galleries feeding these shafts are free of sludge is paramount. A seized idler shaft within the FAW الروسية توقيت والعتاد المنطق will shear its mounting bolts, مما يؤدي إلى عطل كارثي في المحرك.

أخيراً, verify the torque on all سداسي مقبس رأس غطاء رأس السحابات. These screws can loosen over time due to the harmonic vibrations of the diesel engine. If a screw backs out, it can fall into the gear mesh, shattering teeth and jamming the FAW الروسية توقيت والعتاد المنطق آلية. Use of thread locker and adherence to factory torque specs is the only way to guarantee the security of this vital system.

خاتمة: The Heartbeat of the Engine

ال FAW الروسية توقيت والعتاد المنطق is an engineering marvel designed to provide absolute precision in one of the world’s toughest environments. By using a robust all-gear drive instead of belts, FAW ensures that the CA3250P66K24L1TE5Z engine remains perfectly synchronized for hundreds of thousands of kilometers. كل مكون, من الضخم Crankshaft Timing Gear to the smallest thrust plate, plays a vital role in this reliability.

لأصحاب الأسطول, maintaining this system with genuine parts is non-negotiable. Aftermarket gears often lack the precise tooth profile and surface hardening required to survive in the FAW الروسية توقيت والعتاد المنطق حَشد. من خلال الاستثمار في جودة تصنيع المعدات الأصلية, you ensure that your trucks continue to deliver the power and efficiency demanded by the Russian logistics industry, regardless of the freezing temperatures they face.

التعبئة والتغليف والخدمات اللوجستية

أجزاء فاو, بما في ذلك مجموعة كتلة الأسطوانة, يتم تعبئتها بعناية لضمان الولادة الآمنة. يتم تأمين كل مكون في مواد واقية لمنع الضرر أثناء النقل. تضمن الشبكة اللوجستية الشحنات في الوقت المناسب في جميع أنحاء العالم, دعم عمليات الصيانة الفعالة. فيما يلي صورة توضح العبوة القياسية لقطع غيار شاحنات FAW, إظهار الاهتمام بالتفاصيل في التعامل والتخزين.

يقلل أسلوب التغليف هذا من مخاطر التآكل أو التلف الناتج عن الصدمات, ضمان وصول أجزاء مثل FAW Cylinder Block Assembly في حالة ممتازة. يمكن للعملاء الاعتماد على الخدمات اللوجستية التي تقدمها FAW للحصول على الجودة والموثوقية المتسقة.