FAW Russian Heat Sink Logic: Fortifying the Single Thermal Core for Unmatched Arctic Reliability

The FAW Russian Heat Sink Logic assembly represents the absolute pinnacle of thermal management for the CA3250P66K24L1TE5Z dump truck. Designed to operate where standard cooling systems fail, this assembly serves as the primary thermodynamic exchange point for the heavy-duty diesel engine. It balances the immense heat rejection requirements of high-load mining with the brutal reality of -40°C ambient air. This guide explores the engineering behind this critical component.

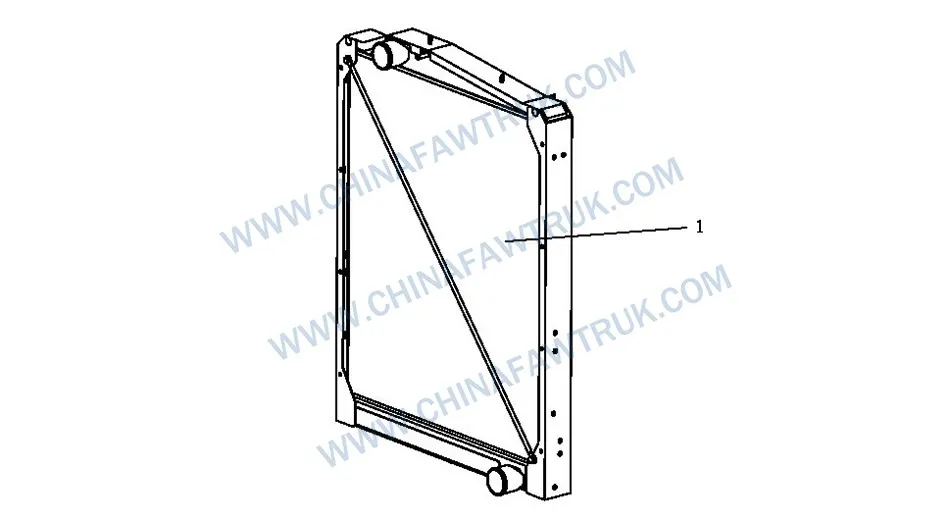

FAW Russian Heat Sink Logic Assembly

The Core Logic: Radiator Assembly Dynamics

The FAW Russian Heat Sink Logic centers entirely around the Radiator Assembly (Part No. 1301010-61C). While it appears as a single part number, it is a complex amalgamation of tubes, fins, headers, and side tanks fused into a singular thermal exchange unit. The primary function of the FAW Russian Heat Sink Logic is dissipating waste heat from combustion. In a heavy-duty dump truck, this heat load is immense, often exceeding hundreds of kilowatts during full-load climbs.

This design differs significantly from standard highway versions. It features a high-efficiency core with a specific fin pitch calculated to prevent clogging from coal dust and silica particles. The “Logic” in the FAW Russian Heat Sink Logic name refers to the system’s ability to maintain thermal equilibrium. In the Arctic, the temperature differential between the 90°C coolant and the -40°C ambient air creates a massive potential for heat transfer.

If uncontrolled, this leads to dangerous overcooling. The core density of the FAW Russian Heat Sink Logic is engineered to handle this. If the radiator were too efficient, it would cause “cold running” issues, such as loose piston clearances and oil consumption. Conversely, if insufficiently robust, the engine would overheat during stationary idling when airflow is minimal.

The internal architecture involves rows of flattened aluminum tubes. Inside these tubes, turbulators disrupt the laminar flow of the coolant. This turbulence ensures hot fluid constantly mixes against the tube walls, maximizing heat transfer. The FAW Russian Heat Sink Logic relies on this to maintain efficiency even when coolant flow varies with RPM, matching thermal rejection to engine output perfectly.

Metallurgical Fortification: Aluminum Construction

Material choice for the FAW Russian Heat Sink Logic is dictated by the harsh environment. The core uses a specialized aluminum alloy. Aluminum is preferred over copper-brass for its superior strength-to-weight ratio and resistance to vibration fatigue. In the Russian Arctic, treacherous roads subject the chassis to violent shocks. A heavy copper radiator would place immense stress on mounting points, leading to failure.

The lighter aluminum construction of the FAW Russian Heat Sink Logic reduces inertial load, ensuring the assembly remains intact during off-road hauling. Corrosion resistance is another critical factor. Russian highways are treated with corrosive chloride-based de-icing salts. The FAW Russian Heat Sink Logic undergoes a specialized brazing process in a controlled atmosphere furnace (CAB).

This creates uniform, flux-free joints between tubes and headers, inherently resistant to external corrosion. Furthermore, the side tanks are reinforced with glass-filled polymers to resist impact from flying stones and ice chunks. The interface between the core and tanks is a critical failure point in lesser radiators.

The FAW Russian Heat Sink Logic utilizes crimping technology with a high-durometer EPDM gasket. This gasket must remain flexible at -40°C. Inferior gaskets harden and shrink, leading to leaks. FAW’s specification ensures the radiator maintains system pressure without weeping fluid, preserving the FAW Russian Heat Sink Logic system’s integrity over years of service.

Arctic Physics: Managing Thermal Shock

A severe threat to the FAW Russian Heat Sink Logic is thermal shock. Imagine a truck parked overnight at -35°C; the core contracts significantly. Upon starting, the thermostat opens, sending a surge of hot coolant into the frozen radiator. This rapid expansion creates immense stress on joints. The design incorporates expansion zones allowing the core to expand thermally without tearing.

This elasticity is crucial for longevity in stop-start mining operations. Additionally, fluid dynamics within the FAW Russian Heat Sink Logic must account for viscous coolants. To prevent freezing, operators use thick, high-concentration glycol mixtures. The tube geometry is optimized to reduce flow restriction, allowing effective circulation even during cold starts.

High flow restriction would lead to pump cavitation and localized overheating, defeating the system’s purpose. The aerodynamic profile of the fins also plays a role. In snowy conditions, powder can block airflow. The fin density of the FAW Russian Heat Sink Logic is carefully balanced to allow small debris to pass through.

This self-cleaning characteristic minimizes manual maintenance and prevents dangerous overheating caused by external ice blockage. By managing both internal fluid viscosity and external airflow, the FAW Russian Heat Sink Logic ensures consistent performance regardless of the weather conditions.

System Integration: The Logic of Connectivity

The FAW Russian Heat Sink Logic does not operate in isolation. It works in conjunction with the intercooler and engine fan. The radiator acts as the structural backbone for the cooling stack. Its mounting points must align precisely with adjacent brackets to ensure a consistent air gap. If this gap varies, airflow turbulence increases, reducing overall efficiency.

Furthermore, the pressure cap regulates the internal pressure of the FAW Russian Heat Sink Logic. Maintaining correct pressure prevents coolant from boiling at hot spots. The radiator is tested to withstand pressures well above operating ratings to provide a safety margin. This is vital during heavy engine braking when water pump speeds maximize.

The structural integrity ensures it never becomes the weak link. Finally, inlet and outlet ports feature rolled beads to secure large coolant hoses. In the FAW Russian Heat Sink Logic, these ports facilitate natural thermal siphoning after shutdown, eliminating hot spots. Every dimension is calculated to protect the vehicle’s heart from Arctic cold and combustion heat.

Component Breakdown: 89. Radiator Logic Assembly

| No. |

Part Number |

Part Name |

Qty |

| 1 |

1301010-61C |

Radiator Assembly |

1 |

Conclusion: The Singular Guardian

The FAW Russian Heat Sink Logic assembly serves as the singular, indispensable guardian of the engine’s thermal health. While it appears as a standalone component, its function is deeply integrated into the truck’s survival. From its vibration-resistant aluminum core to optimized internal flow dynamics, every aspect manages the battle between heat and Arctic cold.

For fleet managers, the Radiator Assembly is a critical maintenance item. External cleaning, coolant checks, and vibration inspections are essential. Replacing this unit with a generic radiator invites disaster; inferior cores cannot handle the thermal shock of the CA3250P66K24L1TE5Z. Investing in the genuine FAW Russian Heat Sink Logic ensures continuous, reliable operation and delivery of payloads rather than downtime.

Packaging and Logistics

FAW parts, including the Cylinder Block Assembly, are packaged with care to ensure safe delivery. Each component is secured in protective materials to prevent damage during transit. The logistics network guarantees timely shipments worldwide, supporting efficient maintenance operations. Below is an image illustrating the standard packaging for FAW truck parts, showcasing the attention to detail in handling and storage.

This packaging approach minimizes the risk of corrosion or impact damage, ensuring that parts like the FAW Cylinder Block Assembly arrive in perfect condition. Customers can rely on FAW’s logistics for consistent quality and reliability.