Welcome to this essential technical breakdown of the FAW In-Vehicle Information Service Terminal. This component is the central “T-Box” or “Telematics Brain” for the FAW Jiefang CA4251P66K24T1A3E5 6×4 diesel semi-trailer tractor. It is a highly advanced Electronic Control Unit (ECU) that functions as the truck’s primary communications gateway, bridging the gap between the vehicle’s internal computer networks and the outside world via the cellular network.

The “Logic Assembly” designation is critical. This is not a simple data port; it is a powerful computer. The FAW In-Vehicle Information Service Terminal (P/N: 7913010A54W-000) has its own processor, memory, and 4G/GPS modems. Its “logic” is to acquire data from the truck (via CAN bus), process it, and transmit it to fleet managers for remote diagnostics, real-time tracking, and driver log compliance.

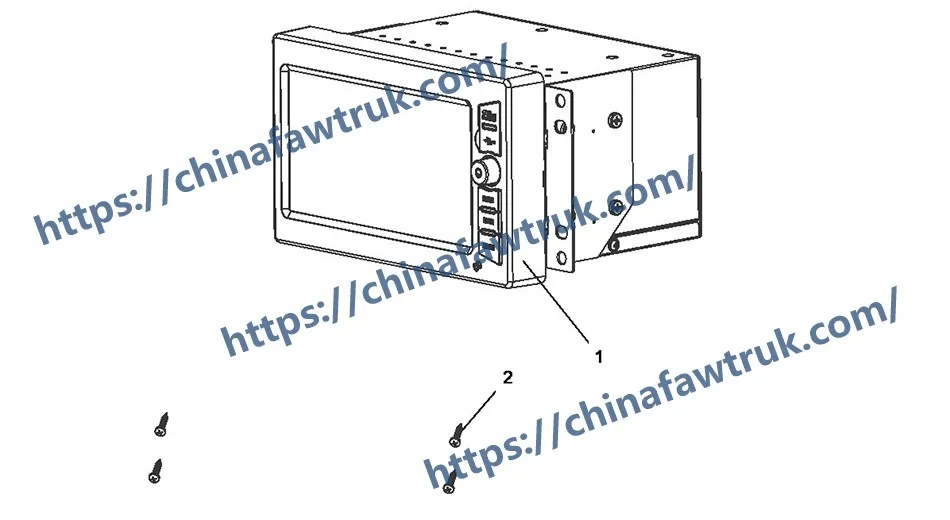

This in-depth guide is a critical resource for technicians and fleet managers. We will deconstruct the entire assembly into its two simple, but critical, component types. We will explore the complex “5-in-1” logic of the main terminal itself, identifying it as the primary Minimum Serviceable Unit (MSU). We will also analyze the specific ‘Cross recessed pan head self-tapping screw’ (CQ2714216) used to mount it.

This is the “longer” and most complex module. The ‘Vehicle information service terminal assy’ (7913010A54W-000) is the entire FAW In-Vehicle Information Service Terminal. It is a sealed, non-repairable “black box” and the primary Minimum Serviceable Unit (MSU). Its “logic” is not physical, but functional. We can deconstruct it into five core logical functions.

1. Logic One: The CAN Bus Interface (The “Ears”)

The terminal’s first function is to “listen.” It is wired directly into the vehicle’s J1939 CAN bus network. This two-wire digital highway is where all the truck’s computers talk. The FAW In-Vehicle Information Service Terminal constantly monitors this data stream, “listening” for key information from other ECUs.

It “hears” live data from the Engine ECU (RPM, fuel consumption, oil pressure, coolant temp), the ABS/EBS module (braking events, stability control), and the Body Control Module (BCM) (door open, lights on). This raw data is the “what” and “how” of the vehicle’s operation.

2. Logic Two: The GNSS Receiver (The “Where”)

The terminal’s second function is to know *where* it is. It contains a high-sensitivity Global Navigation Satellite System (GNSS) receiver. This receiver links to the ‘Multifunctional antenna assy’ (7903010-61B) to get a live, constant signal from satellites, primarily GPS and/or Beidou (BDS).

This provides precise, time-stamped location data. This “where” logic is what gives context to the CAN bus data. The system now knows not just *that* a harsh braking event occurred, but *exactly where* on the route it happened.

3. Logic Three: The Telematics Modem (The “Voice”)

The third function is to “speak.” The FAW In-Vehicle Information Service Terminal houses a 4G/LTE cellular modem, complete with a SIM card. This is its connection to the outside world. It takes the “what” (CAN data) and the “where” (GPS data), packages it, and transmits it over the mobile network to a secure server.

This is the core of “telematics.” It allows a fleet manager, sitting in an office hundreds of miles away, to see the truck’s location, speed, and fuel level on a live map. It also allows for two-way communication, such as sending new dispatch orders or route information *to* the truck’s dashboard.

4. Logic Four: Remote Diagnostics (The “Doctor”)

This is perhaps the most valuable “logic” for vehicle health. The FAW In-Vehicle Information Service Terminal constantly monitors the CAN bus for Diagnostic Trouble Codes (DTCs), or “fault codes.”

When the driver sees a “Check Engine” light, the terminal *already knows* the specific code (e.g., “P0128 – Coolant Thermostat Malfunction”). It instantly transmits this code to the service manager. This “predictive maintenance” logic is revolutionary. The manager can order the exact thermostat part and schedule service *before* the driver even finishes the route, drastically reducing vehicle downtime and preventing a minor issue from becoming a major engine failure.

5. Logic Five: The Driver Log Interface (The “Logbook”)

The final function is legal compliance. The terminal often serves as the data-gathering “brain” for the digital tachograph (like the ‘Tachograph assy’ 7914010-61B). It combines CAN bus data (Engine On/Off, Engine Hours) with GPS data (Vehicle Speed, Location) to create a secure, tamper-proof Electronic Driver Log (EDL).

This automates the tracking of driver Hours of Service (HOS), eliminating paper logbooks and ensuring the fleet is in full legal compliance. As the central MSU, any failure in the FAW In-Vehicle Information Service Terminal can compromise all five of these functions, making its replacement a high-priority service task.

The second component type is the mounting hardware, the ‘Cross recessed pan head self-tapping screw’ (CQ2714216). The parts list calls for four (4) of these, identifying them as a key MSU for installation.

The “logic” of these fasteners is critical. The FAW In-Vehicle Information Service Terminal is a sensitive electronic device. It cannot be allowed to vibrate or shake loose, as this can damage internal solder joints or loosen the critical wiring harness connectors.

These are “self-tapping” screws, meaning they are designed to be driven directly into the plastic sub-frame of the dashboard, where they cut their own threads. This creates a tight, vibration-resistant fit. The 4-point mounting pattern ensures the terminal is rigidly secured.

These screws are a specific MSU. A technician must use these exact OEM screws. Using a standard bolt or a screw with the wrong thread pitch will strip the plastic mounting boss and fail to secure the terminal, leading to rattling and eventual electronic failure.

The following table provides the complete, detailed breakdown of all 2 component types identified in the FAW In-Vehicle Information Service Terminal diagram for the FAW CA4251P66K24T1A3E5 tractor.

| Mark | Part No. | Part Name | Quantity |

|---|---|---|---|

| 1 | 7913010A54W-000 | Vehicle information service terminal assy (see drawing) | 1 |

| 2 | CQ2714216 | Cross recessed pan head self-tapping screw | 4 |

The specifications for the FAW In-Vehicle Information Service Terminal are defined by its role as the central telematics control unit (TCU). It is a “black box” MSU that integrates multiple communication and processing technologies.

| Vehicle Application | FAW Jiefang CA4251P66K24T1A3E5 6×4 Tractor |

| Component Group | FAW In-Vehicle Information Service Terminal |

| Main Assembly P/N | 7913010A54W-000 |

| Common Name | Telematics Control Unit (TCU) or “T-Box” |

| System Voltage | 24V DC (Nominal) |

| Logic Function 1 | CAN Bus Monitoring (J1939) |

| Logic Function 2 | GNSS (GPS/BDS) Positioning |

| Logic Function 3 | 4G/LTE Cellular Data Transmission |

| Logic Function 4 | Remote Diagnostics (DTC Reporting) |

| Logic Function 5 | Electronic Driver Log (Tachograph) Interface |

| MSU 1 (Main) | ‘Vehicle information service terminal assy’ (Sealed Unit) |

| MSU 2 (Hardware) | ‘Cross recessed pan head self-tapping screw’ (CQ2714216) |

| Hardware Quantity | 4 |

FAW parts, including the Cylinder Block Assembly, are packaged with care to ensure safe delivery. Each component is secured in protective materials to prevent damage during transit. The logistics network guarantees timely shipments worldwide, supporting efficient maintenance operations. Below is an image illustrating the standard packaging for FAW truck parts, showcasing the attention to detail in handling and storage.

This packaging approach minimizes the risk of corrosion or impact damage, ensuring that parts like the FAW Cylinder Block Assembly arrive in perfect condition. Customers can rely on FAW’s logistics for consistent quality and reliability.