Welcome to this critical technical guide on the FAW Central Bridge Drive Shaft. This is the complete “inter-axle” driveshaft assembly for the FAW Jiefang CA4251P66K24T1A3E5 6×4 diesel semi-trailer tractor. This component is the vital link that completes the “6×4” capability, connecting the first drive axle to the second.

The FAW Central Bridge Drive Shaft (Part No. 2205060A91W) is responsible for transmitting 100% of the torque from the “forward” drive axle’s output yoke to the “rear” drive axle’s input yoke. This short, high-torque shaft must operate at extreme angles while handling the full, multiplied torque of the engine.

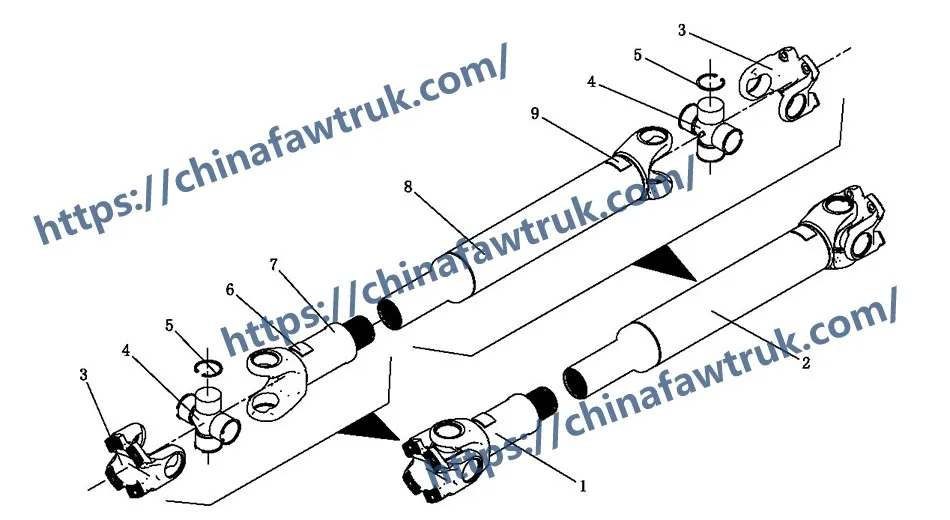

This in-depth guide is an essential resource for professional driveline technicians, fleet managers, and parts specialists. We will deconstruct the entire FAW Central Bridge Drive Shaft assembly into its 9 serviceable components, including the main shaft, the universal joints, the critical “slip joint,” and the precision shims required for balancing.

The FAW Central Bridge Drive Shaft assembly is comprised of several core forged-steel components. The main shaft is the ‘Inter-axle driveshaft tube, welding fork & spline sleeve assy’ (2205015-91W). This is the “bone” of the assembly, a hollow, high-strength steel tube that is precision-welded and dynamically balanced. It is designed with a “welded fork” on one end and a “spline sleeve” on the other.

The ends of the FAW Central Bridge Drive Shaft are the yokes, which connect to the axles and the U-joints:

This “slip joint” is a critical part of the FAW Central Bridge Drive Shaft‘s logic. As the truck’s suspension compresses and rebounds, the distance between the two drive axles changes. This slip joint allows the FAW Central Bridge Drive Shaft to expand and contract like a telescope, preventing this movement from destroying the transmission or axle bearings. A worn or “clunking” slip joint is a common failure point, usually from a lack of grease.

The “logic” of the FAW Central Bridge Drive Shaft is its ability to transmit full rotational power at an angle. This is achieved by the ‘Cross & needle bearing assy’ (2205030B761), also known as the Universal Joint or “U-joint.” The parts list calls for two of these, one for each end of the shaft.

This component is a “double hinge.” It consists of a central “cross” or “spider” with four precision-ground, hardened steel arms (trunnions). Each arm is fitted with a “cap” that contains dozens of small “needle roller bearings.” These four caps are then secured into the “yokes” of the driveshaft and the axle flange.

This design allows the FAW Central Bridge Drive Shaft to “bend” up, down, left, and right, perfectly accommodating the constant movement of the drive axles as the truck’s suspension articulates over rough terrain.

These U-joints are the primary wear item in any FAW Central Bridge Drive Shaft. They operate under immense torque and must be periodically greased. If the needle bearings run dry, they will be destroyed by friction, leading to a “chirping” or “squeaking” noise that is tied to road speed. If ignored, this will become a “clunk” (as the cross slams back and forth) and will eventually lead to a catastrophic failure of the FAW Central Bridge Drive Shaft, which can sever air and fuel lines or even puncture the transmission housing.

The final components of the FAW Central Bridge Drive Shaft are the precision alignment parts. The parts list calls for 8 ‘Circlips’ (2205041-AOM through 2205048-AOM) and multiple sets of ‘Shims’ (2205081-AOM series and 2205071-AOM series).

The ‘Circlips’ are the snap-rings that are used to retain the U-joint’s bearing caps within the yokes. The fact that there are 8 different part numbers for 8 circlips indicates that these are **selective fit** circlips. This means they come in minutely different thicknesses. A technician must use these to perfectly center the U-joint “cross” within the yoke, preventing any side-to-side “play” that would cause vibration.

The ‘Shims’ (marked “按需” – “as needed”) are even more critical. These are paper-thin, precision-cut shims used for **dynamic balancing**. During manufacturing, the complete FAW Central Bridge Drive Shaft is spun on a balancing machine. The machine detects tiny “heavy spots,” and the technician adds these shims (often under the U-joint caps) to achieve perfect balance.

It is **critically important** to never lose, mix up, or fail to reinstall these shims. Removing even one of these “as needed” shims will destroy the shaft’s balance, leading to a severe vibration that can only be fixed by having the entire FAW Central Bridge Drive Shaft re-balanced by a driveline specialist.

The following table provides the complete, detailed breakdown of all 9 component groups identified in the ‘Central Bridge Drive Shaft’ diagram for the FAW CA4251P66K24T1A3E5 tractor. This FAW Central Bridge Drive Shaft is a precision-balanced assembly.

| Mark | Part No. | Part Name | Quantity |

|---|---|---|---|

| 1 | 2205050B761 | Splined yoke & universal joint assy | 1 |

| 2 | 2205060A91W | Inter-axle driveshaft & universal joint assy | 1 |

| 3 | 2205023B761 | Flange yoke | 1 |

| 4 | 2205030B761 | Cross & needle bearing assy (U-Joint) | 2 |

| 5 | 2205041~AOM | Circlip (Set of 8, P/N: 2205041-AOM to 2205048-AOM) | 8 |

| 6 | 2205081~AOM | Shim (See 2205081-AOM to 2205089-AOM) | As needed |

| 7 | 2205020B761 | Splined yoke assy | 1 |

| 8 | 2205015-91W | Inter-axle driveshaft tube, welding fork & spline sleeve assy | 1 |

| 9 | 2205071~AOM | Shim (See 2205071-AOM to 2205079-AOM) | As needed |

The specifications for the FAW Central Bridge Drive Shaft are defined by its function as a high-torque, high-speed, flexible power transmission shaft. This FAW Central Bridge Drive Shaft is a precision-balanced component.

| Vehicle Application | FAW Jiefang CA4251P66K24T1A3E5 6×4 Tractor |

| Component Group | FAW Central Bridge Drive Shaft |

| Common Name | Inter-Axle Driveshaft / Jackshaft |

| Main Assembly P/N | 2205060A91W |

| Main Shaft Tube P/N | 2205015-91W |

| Joint Type | 2x Universal Joints (2205030B761) |

| Length Compensation | 1x Splined Slip-Joint (2205020B761) |

| Connection Type | Flange Yoke (2205023B761) & Splined Yoke (2205050B761) |

| Balancing System | Selective Fit Circlips (220504x-AOM) & Shims (AOM series) |

| Primary Function | To transmit torque from the first drive axle to the second drive axle, allowing for suspension articulation. |

FAW parts, including the Cylinder Block Assembly, are packaged with care to ensure safe delivery. Each component is secured in protective materials to prevent damage during transit. The logistics network guarantees timely shipments worldwide, supporting efficient maintenance operations. Below is an image illustrating the standard packaging for FAW truck parts, showcasing the attention to detail in handling and storage.

This packaging approach minimizes the risk of corrosion or impact damage, ensuring that parts like the FAW Cylinder Block Assembly arrive in perfect condition. Customers can rely on FAW’s logistics for consistent quality and reliability.