Welcome to this critical technical guide on the FAW Roof Assembly (Part No. 1702111BA9P). This component is the “Top Cover” or “Shifter Tower” assembly for the main gearbox in the FAW Jiefang CA4251P66K24T1A3E5 6×4 diesel semi-trailer tractor. This is the complete “logic” system that translates driver input into gear selection.

The FAW Roof Assembly is the command center for the manual transmission. It is not part of the vehicle’s cabin, but rather the complex, serviceable “top lid” of the transmission housing. It contains all the forks, shafts, and interlocks that physically move the synchronizers inside the gearbox. The precision of this FAW Roof Assembly is what ensures a smooth, clean, and reliable shift.

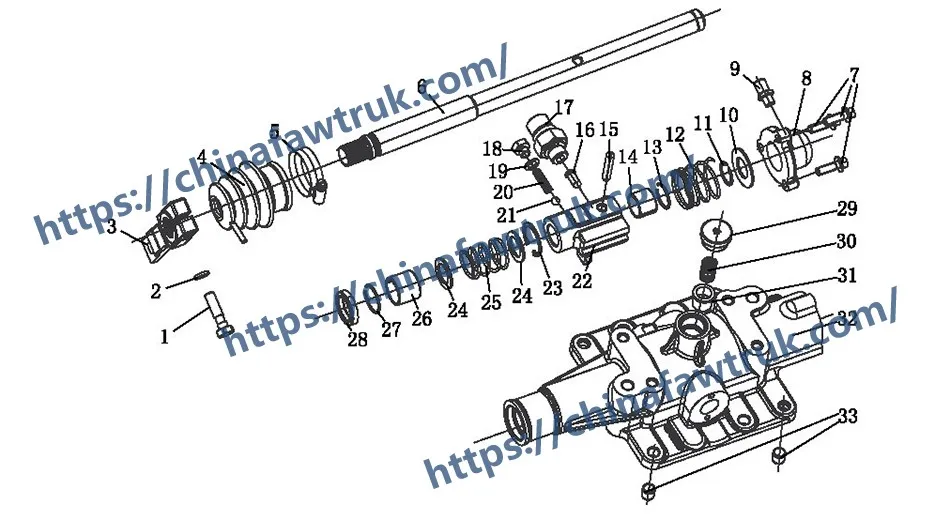

This in-depth guide is an essential resource for professional transmission technicians and fleet managers. We will deconstruct the entire FAW Roof Assembly into its 33 serviceable components, including the main ‘Shift arm’ (1702226AA0L), the ‘Shift shaft’ (1702121BA9P), the ‘Neutral switch’ (3774010-367), and all the critical detent springs and seals.

The heart of the FAW Roof Assembly is the ‘Top cover’ (1702111BA9P). This is the main structural housing, precision-cast from aluminum or iron, that bolts to the top of the main transmission case. This component is the “skeleton” for all the other internal control components.

This housing is not just a lid. It is precision-machined with multiple parallel bores that are designed to hold the shift shafts (or “rails”). The alignment of these bores must be perfect, as they ensure the shift forks are held in the exact correct position over the synchronizer sleeves. Any warping or damage to this main housing will make shifting impossible. This core component is the foundation of the FAW Roof Assembly.

This ‘Top cover’ also serves as the main sealing surface. It is sealed to the transmission case by a large gasket (not listed) to prevent gear oil from leaking out. The ‘Dust cover-top cover’ (1702231EA7G) is a critical rubber boot that seals the point where the main shift arm (1702226AA0L) exits the housing, preventing water, dust, and road grime from entering the transmission and contaminating the oil. The entire FAW Roof Assembly is designed as a sealed unit.

The “logic” of the FAW Roof Assembly is how it converts the driver’s “H-pattern” shift into the movement of a single, specific shift fork. This begins with the ‘Shift arm’ (1702226AA0L), which is the main lever that the external gear stick connects to. This arm pivots on the ‘Shaft-shift’ (1702121BA9P), a hardened steel shaft.

When the driver moves the stick left or right (selecting a “gate,” e.g., 1-2 vs 3-4), this ‘Shift arm’ moves the ‘Shaft-shift’ to line up with a specific ‘Shift fork head/lug’ (1702226BA9P). When the driver pushes the stick forward or back, the arm then pushes or pulls this specific lug.

This ‘Shift fork head/lug’ is attached to a rail, which in turn is attached to the main shift forks (detailed in Assembly 153). This action slides the fork, engaging the gear. The ‘Sliding bushing-top cover’ (1702168BA9P and 1702214BA9P) units are the low-friction bronze bushings that allow the shift shafts to slide smoothly with minimal effort. This mechanical logic is the “muscle” of the FAW Roof Assembly.

The FAW Roof Assembly also contains a critical “detent” system. This is what gives the shifter its positive “click” and prevents the transmission from vibrating out of gear. This system is comprised of springs, plungers, and balls:

Each shift rail (shaft) has small grooves or “detents” machined into it (one for each gear, and one for neutral). A ‘Plunger’ and ‘Spring’ are aligned with each rail. When a gear is selected, the ‘Steel ball’ or ‘Plunger’ is forced by the spring into one of these grooves. This “locks” the rail in place, preventing vibration from “popping it out of gear.” The “click” the driver feels is this ball dropping into its groove. These springs are a critical part of the FAW Roof Assembly‘s “feel.”

This FAW Roof Assembly also contains the interlock system, which is a set of pins (like ‘Parallel cut pin’ 1701656-A2K and ‘Post pin’ 1702242-A9P) that physically block the *other* shift rails from moving once one rail has been selected. This is the safety logic that makes it impossible to select two gears at once.

A key electronic component of the FAW Roof Assembly is the ‘Neutral switch assembly’ (3774010-367). This is a simple but critical sensor. It is a plunger-style switch that is threaded into the ‘Top cover’.

When all the shift rails are in their “neutral” position, a groove aligns under this switch, allowing its plunger to drop, which closes an electrical circuit. This sends a “Neutral” signal to the truck’s main ECU. This signal is essential for:

A failure of this single switch on the FAW Roof Assembly can lead to a “no-start” condition that can be very difficult to diagnose.

The FAW Roof Assembly must be perfectly sealed from the elements but also able to “breathe.” The ‘Breather plug assembly’ (1702165-A8L) is a one-way “cap” that allows internal pressure (which builds as the gear oil heats up) to vent *out*, but prevents water and dust from getting *in*.

The ‘Oil seal assembly’ (1702235-A7G) is a critical radial seal that is installed on the main ‘Shaft-shift’ (1702121BA9P). It prevents the gear oil inside the FAW Roof Assembly from leaking out where the shift shaft enters.

The entire FAW Roof Assembly is held together and mounted with a large number of high-grade fasteners. This includes ‘Hex cap bolts’ (CQ1501040), ‘Hex flange bolts’ (Q1840825), ‘Hex screw plugs’ (1702148-A6H, 1702149-A8L), ‘Spring gaskets’ (Q40310), and ‘Elastic retaining rings’ (Q43322, Q43226, Q43034, Q43230) to secure all the pins and shafts.

The following table provides the complete, detailed breakdown of all 33 components identified in the ‘Top Cover Assembly’ (referred to as the FAW Roof Assembly) diagram for the FAW CA4251P66K24T1A3E5 tractor.

| Mark | Part No. | Part Name | Quantity |

|---|---|---|---|

| 1 | CQ1501040 | Hex head bolt | 1 |

| 2 | Q40310 | Spring gasket | 1 |

| 3 | 1702226AA0L | Shift arm | 1 |

| 4 | 1702231EA7G | Dust cover-top cover | 1 |

| 5 | CQ67660B | Worm Drive Hose Clamp B-Type | 1 |

| 6 | 1702121BA9P | Shaft-shift | 1 |

| 7 | Q1840825 | Hex flange bolt, coarse rod (Standard Type) | 3 |

| 8 | 1702217BA9P | End cap | 1 |

| 9 | 1702165-A8L | Breather plug assembly | 1 |

| 10 | 1702236BA9P | Large retaining ring | 1 |

| 11 | Q43322 | Shaft elastic retaining ring | 2 |

| 12 | 1702131B73B | Return spring-high gear | 1 |

| 13 | Q43226 | Steel wire retaining ring | 1 |

| 14 | 1702168BA9P | Sliding bushing-top cover | 1 |

| 15 | 1701656-A2K | Parallel cut pin | 1 |

| 16 | 1702242-A9P | Post pin | 1 |

| 17 | 3774010-367 | Neutral switch assembly | 1 |

| 18 | 1702148-A6H | Screw plug | 1 |

| 19 | 1702141-A6H | Gasket | 1 |

| 20 | 1702146-A6H | Spring | 1 |

| 21 | Q967105 | Steel ball | 1 |

| 22 | 1702226BA9P | Shift fork head/lug | 1 |

| 23 | Q43034 | Hole elastic retaining ring | 1 |

| 24 | 1702237BA9P | Small retaining ring | 2 |

| 25 | 1702132BA9P | Return spring-low gear | 1 |

| 26 | 1702214BA9P | Sliding bushing-top cover | 1 |

| 27 | Q43230 | Steel wire retaining ring | 1 |

| 28 | 1702235-A7G | Oil seal assembly (as-per-sample) | 1 |

| 29 | 1702149-A8L | Screw plug | 1 |

| 30 | 1702147BA9P | Spring-reverse pin | 1 |

| 31 | 1702146-A8L | Plunger | 1 |

| 32 | 1702111BA9P | Top cover | 1 |

| 33 | 1701012-11 | Locating ring | 2 |

The specifications for the FAW Roof Assembly are defined by its function as the transmission’s mechanical “logic” board. This FAW Roof Assembly (Top Cover) is responsible for all gear selection.

| Vehicle Application | FAW Jiefang CA4251P66K24T1A3E5 6×4 Tractor |

| Component Group | FAW Roof Assembly (Transmission Top Cover) |

| Main Housing P/N | 1702111BA9P (Top Cover) |

| System Type | Mechanical Shift Rail / Fork Assembly |

| Shift Forks | Complete set for 1st-6th gears and Reverse |

| Main Shift Arm | 1702226AA0L |

| Safety Logic 1 (Interlock) | Interlock Plates and Steel Balls (Q967105) |

| Safety Logic 2 (Detent) | Self-Locking Springs (1702061AA4P) & Plungers |

| Electronic Sensor | 1x Neutral Switch Assembly (3774010-367) |

| Sealing | Dust Cover (1702231EA7G), Oil Seal (1702235-A7G), Breather (1702165-A8L) |

FAW parts, including the Cylinder Block Assembly, are packaged with care to ensure safe delivery. Each component is secured in protective materials to prevent damage during transit. The logistics network guarantees timely shipments worldwide, supporting efficient maintenance operations. Below is an image illustrating the standard packaging for FAW truck parts, showcasing the attention to detail in handling and storage.

This packaging approach minimizes the risk of corrosion or impact damage, ensuring that parts like the FAW Cylinder Block Assembly arrive in perfect condition. Customers can rely on FAW’s logistics for consistent quality and reliability.