FAW Русский механизм заднего хода в сборе: Инженерное дело 5 Жизненно важные компоненты для устойчивого обратного крутящего момента

The FAW Русский механизм заднего хода в сборе is the directional inverter of the CA3250P66K24L1TE5Z transmission, enabling the massive dump truck to maneuver in confined mining pits. Unlike forward gears that share loads, this assembly bears the unique stress of high-torque reverse crawling. В этом руководстве анализируются 5 стратегические компоненты, from the idler gear to the needle bearings, designed to survive the brutal -40°C Siberian winter.

FAW Русский механизм заднего хода в сборе

Torque Inversion: The Reverse Idler Gear

Центральный компонент FAW Русский механизм заднего хода в сборе это Reverse Idler Gear (Часть №. 1701481-A7G). This gear performs the critical mechanical function of reversing the rotation direction between the countershaft and the main shaft. Unlike forward gears that are often synchronized for smooth engagement at speed, the reverse idler is typically engaged from a standstill. Однако, in the rough operations of a Russian mine, drivers often attempt to engage reverse while the vehicle is still rolling slightly forward. This places an immense shock load on the gear teeth.

To withstand this abuse, а FAW Русский механизм заднего хода в сборе utilizes a gear forged from premium case-hardened steel (likely 20CrMnTi or similar). The carburization process creates an extremely hard outer shell on the gear teeth to resist pitting and wear, while maintaining a softer, пластичный сердечник. This ductility is crucial in the Arctic. При -40°С, fully hardened steel becomes brittle and can shatter under impact. The metallurgical profile of the FAW gear ensures it can absorb the shock of engagement without tooth fracture.

The geometry of the teeth in the FAW Русский механизм заднего хода в сборе is also optimized. While older transmissions used straight-cut spur gears for reverse (causing the characteristic “whine”), modern heavy-duty transmissions often employ helical gears for higher torque capacity. The helix angle increases the contact ratio, meaning more teeth are in mesh at any given time. This distributes the load of backing a 30-ton load up an icy incline across a larger surface area, preventing premature failure of the idler gear.

Ротационная поддержка: Shaft and Needle Bearings

The gear rotates on the Idler Shaft (Часть №. 1701482-А0Л). В FAW Русский механизм заднего хода в сборе архитектура, this shaft is stationary; it is fixed to the transmission housing, and the gear spins around it. This design requires the shaft to possess a surface finish of exceptional smoothness and hardness. Any surface imperfection would act as a grinding tool against the bearing. The shaft acts as a structural beam, resisting the bending forces generated by the separating force of the gear mesh.

Interposed between the static shaft and the spinning gear is the Needle Roller Bearing (Часть №. 1701485-A7G). Needle bearings are chosen for the FAW Русский механизм заднего хода в сборе because of their high load-carrying capacity relative to their small radial cross-section. They provide a rigid support that maintains precise gear alignment. Однако, needle bearings are sensitive to lubrication starvation. В русскую зиму, gear oil thickens significantly.

Чтобы бороться с этим, а FAW Русский механизм заднего хода в сборе relies on strategically placed oil channels within the shaft or gear hub. These channels direct the viscous oil into the needle rollers. The bearing cage is likely made from a polymer or steel robust enough to push through the thick oil without collapsing. If this bearing fails, the idler gear will wobble, leading to poor tooth contact, шум, и в конце концов, the destruction of the mating main shaft gear. Таким образом, the quality of this bearing is the linchpin of the reverse system.

Position Control: Washers and Snap Rings

Helical gears generate axial thrust—a force that tries to push the gear along the shaft. To contain this force, а FAW Русский механизм заднего хода в сборе employs two units of Шайба – Reverse Gear (Часть №. 1701487-A7G). These are not simple spacers; they act as thrust bearings. Placed on either side of the idler gear, they provide a hardened surface for the gear face to rotate against. They must resist galling and scoring under high thrust loads.

Often, these washers in the FAW Русский механизм заднего хода в сборе feature oil grooves (radial or spiral) to promote a hydrodynamic oil film between the washer and the gear. This film prevents metal-on-metal contact. В сильный мороз, maintaining this film is difficult but essential. The metallurgy of the washers is typically a bronze alloy or hardened steel, chosen to be sacrificial to protect the more expensive gear and housing.

Locking the entire assembly onto the shaft are two units of Защелкнуть кольцо – Reverse Idler Shaft (Часть №. 1701488-A7G). These snap rings fit into precision-machined grooves on the idler shaft. They set the end-play of the gear. If the end-play is too tight, the gear will bind as it heats up and expands. If too loose, the gear will “shuttle” back and forth, causing driveline clunk. The FAW Русский механизм заднего хода в сборе relies on the precise thickness of these rings to maintain the factory-specified tolerance, ensuring smooth operation for the vehicle’s lifespan.

Operational Logic: Reliability in Reverse

The dump truck application involves frequent reversing maneuvers, often under full load while positioning for dumping or loading. The FAW Русский механизм заднего хода в сборе is therefore a high-cycle component. В Российской Арктике, this is compounded by the resistance of the frozen drivetrain fluids. The drag on the idler gear during a -30°C cold start is significant. The assembly’s ability to resist twisting on the shaft keyways (if present) or spinning on the shaft is tested daily.

Более того, the reverse gear is often the lowest ratio in the transmission, providing the highest torque multiplication. This puts the FAW Русский механизм заднего хода в сборе under the highest tooth contact pressure of any gear set. The structural integrity of the idler shaft and the load rating of the needle bearing are the limiting factors for the truck’s reverse gradeability. FAW’s engineering ensures these limits exceed the traction limits of the tires, protecting the mechanical parts from overload.

Поддержание FAW Русский механизм заднего хода в сборе involves checking for excessive noise (whine or clatter) in reverse, which indicates bearing or gear wear. Metal particles in the transmission oil are an early warning sign. Because the idler gear is constantly meshed (though not loaded) in some transmission designs, or engages via a sliding mechanism in others, its condition affects the overall health of the gearbox. Using genuine parts ensures the metallurgy matches the original specification, preventing rapid wear of mating components.

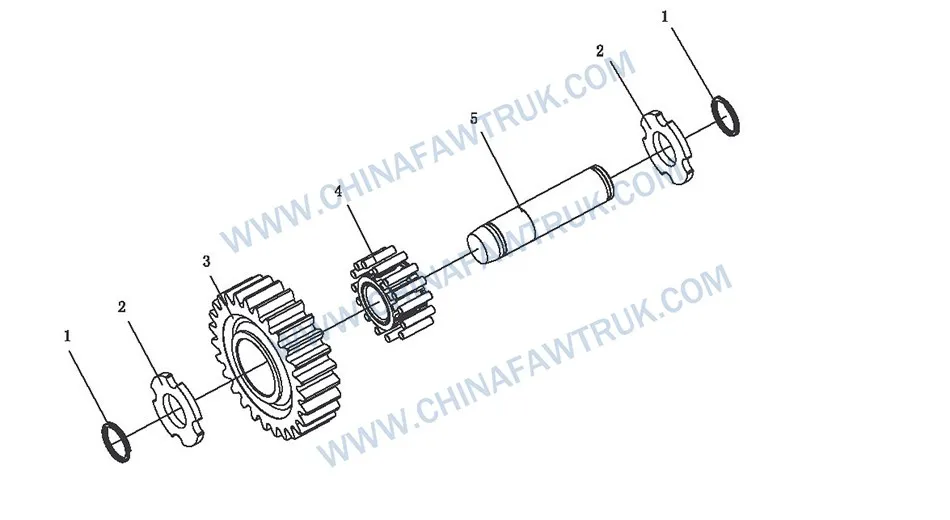

Разбивка компонентов: 107. Reverse Gear Assembly

| Нет. |

Номер детали |

Наименование |

Кол-во |

| 1 |

1701488-A7G |

Защелкнуть кольцо – Reverse Idler Shaft |

2 |

| 2 |

1701487-A7G |

Шайба – Reverse Gear |

2 |

| 3 |

1701481-A7G |

Reverse Idler Gear |

1 |

| 4 |

1701485-A7G |

Needle Roller Bearing |

1 |

| 5 |

1701482-А0Л |

Idler Shaft |

1 |

Заключение: Backward Power, Forward Reliability

The FAW Русский механизм заднего хода в сборе is a compact yet robust system that enables the essential maneuverability of the CA3250P66K24L1TE5Z. Каждый компонент, from the case-hardened idler gear to the precision needle bearing, is selected to handle the extreme torque and environmental challenges of the Russian market. It transforms engine power into controlled reverse motion, ensuring the truck can navigate the tightest and toughest job sites.

For transmission rebuilders, the message is one of precision. The small parts—the snap rings and washers—are just as critical as the gear itself. Neglecting to replace a worn thrust washer can lead to catastrophic gear failure. Используя подлинное FAW Русский механизм заднего хода в сборе набор, operators ensure that their transmission is restored to factory specifications, ready to face another winter of heavy hauling.

Упаковка и логистика

Запчасти ФАВ, включая блок цилиндров в сборе, тщательно упакованы, чтобы обеспечить безопасную доставку. Каждый компонент закреплен защитными материалами для предотвращения повреждений при транспортировке.. Логистическая сеть гарантирует своевременную доставку по всему миру., поддержка эффективных операций по техническому обслуживанию. Ниже приведено изображение, иллюстрирующее стандартную упаковку запчастей для грузовиков FAW., демонстрация внимания к деталям в обращении и хранении.

Такой подход к упаковке сводит к минимуму риск коррозии или ударного повреждения., обеспечение доставки таких деталей, как блок цилиндров FAW в сборе, в идеальном состоянии.. Клиенты могут положиться на логистику FAW для обеспечения стабильного качества и надежности..