Eixo da caixa de engrenagens de transferência russa FAW: Revelação 10 Links Estratégicos para Propulsão Contínua no Ártico

O Eixo da caixa de engrenagens de transferência russa FAW assembly acts as the kinetic bridge between the transfer case and the middle drive axle on the CA3250P66K24L1TE5Z dump truck. In the grueling environment of the Russian Federation, this driveshaft must endure not only massive torque loads but also the severe articulation of the off-road suspension. This guide dissects the assembly into its 10 critical sub-components, analyzing the engineering behind the universal joints, spline yokes, and dynamic balancing weights that define the performance of the Eixo da caixa de engrenagens de transferência russa FAW in -40°C conditions.

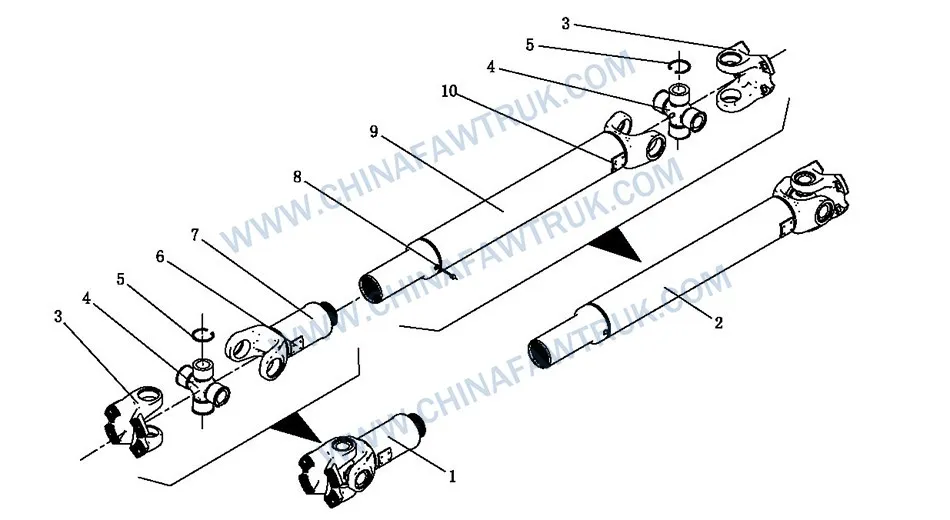

FAW Russian Transfer Gearbox Shaft Assembly

Articulation Logic: The Cross Shaft Assembly

At the pivot points of the Eixo da caixa de engrenagens de transferência russa FAW lie the Cross Shaft and Needle Roller Bearing Assembly (Parte não. 2205030B761). Commonly known as the Universal Joint or U-Joint, this component allows the driveshaft to transmit power at varying angles as the rear suspension moves up and down. No Eixo da caixa de engrenagens de transferência russa FAW projeto, these cross shafts are forged from high-strength alloy steel to resist the immense shear forces generated during low-gear crawling in mining pits.

The needle roller bearings housed within the U-joint caps are critical for smooth operation. To ensure longevity, o Eixo da caixa de engrenagens de transferência russa FAW incorporates the Bico de graxa reto (Parte não. CQ70001) for regular lubrication. No Ártico Russo, proper greasing is essential to purge contaminants and ensure a fresh film of low-temperature lubricant protects the needles. Without this maintenance, o Eixo da caixa de engrenagens de transferência russa FAW joints would quickly seize, leading to severe driveline vibration.

Securing the U-joint caps are the Snap Rings (Números de peças. 2205041-A0M through 2205048-A0M). These rings come in various thicknesses to allow for precise centering of the cross shaft within the yoke. Proper centering is vital for the Eixo da caixa de engrenagens de transferência russa FAW to maintain dynamic balance. If the U-joint is off-center by even a fraction of a millimeter, it creates an eccentric mass that generates destructive harmonic vibrations at highway speeds.

Extension Logic: The Spline Shaft Yoke

O Eixo da caixa de engrenagens de transferência russa FAW must effectively change length. As the truck drives over bumps, the distance between the transfer case and the axle changes constantly. Para acomodar isso, a montagem utiliza o Spline Shaft Yoke and Universal Joint Assembly (Parte não. 2205050-896) e o Spline Shaft Yoke Assembly (Parte não. 2205020-896). These components form a telescoping slip joint that transmits torque while sliding axially.

The internal splines of the Eixo da caixa de engrenagens de transferência russa FAW yoke are coated with a specialized glide material, often Nylon or Rilsan, to reduce friction and prevent “spline lock.” Spline lock occurs when high torque loads prevent the slip yoke from sliding, transmitting suspension shock directly into the transfer case bearings. The advanced coating used in the Eixo da caixa de engrenagens de transferência russa FAW ensures smooth plunging action even under maximum load, protecting the drivetrain components upstream.

Sealing this slip joint is paramount in the dusty, ambiente lamacento de uma pedreira. O Eixo da caixa de engrenagens de transferência russa FAW features a robust dust cap and seal arrangement to keep abrasive grit out of the splines. If the splines become contaminated, they wear rapidly, criando “lash” or free play in the driveline. This lash results in a clunking noise during acceleration and deceleration, a hallmark sign of a worn Eixo da caixa de engrenagens de transferência russa FAW conjunto.

Balance Logic: Tube Assembly and Weights

The main body of the driveshaft is the Middle Axle Driveshaft Tube, Welded Yoke and Spline Sleeve Assembly (Parte não. 2205015-896). This component connects the slip yoke to the fixed yoke. No Eixo da caixa de engrenagens de transferência russa FAW, this tube is manufactured from high-tensile, seamless steel tubing designed to resist torsional twisting. The welds connecting the yokes to the tube are friction-welded for maximum strength and uniformity, critical for maintaining the straightness of the Eixo da caixa de engrenagens de transferência russa FAW.

To eliminate vibration, o Eixo da caixa de engrenagens de transferência russa FAW undergoes a rigorous dynamic balancing process. Small metal plates, known as Balance Sheets (Números de peças. 2205081-A0M through 2205088-A0M and 2205071-A0M through 2205079-A0M), are spot-welded to the tube. These weights counteract any mass imbalances in the casting or welding process. The variety of part numbers indicates different weight masses, allowing for precise calibration of the Eixo da caixa de engrenagens de transferência russa FAW.

No inverno russo, ice buildup on the driveshaft can throw off this delicate balance. The smooth finish of the Eixo da caixa de engrenagens de transferência russa FAW tube helps shed ice and mud. No entanto, if a balance weight is knocked off by road debris, the resulting vibration can be severe enough to crack the transfer case housing. Portanto, inspecting the condition of these weights is a key part of maintaining the Eixo da caixa de engrenagens de transferência russa FAW sistema.

Cold Weather Logic: The 55R Advantage

The part number 2215010-55R for the complete Eixo de transmissão da caixa de transferência e conjunto de junta universal highlights the specific engineering for the Russian market. O “55R” suffix typically denotes a cold-weather package. This includes rubber seals and boots made from low-temperature elastomers that stay flexible at -40°C, preventing the cracking and grease loss common in standard driveshafts.

Além disso, the grease pre-packed into the Eixo da caixa de engrenagens de transferência russa FAW U-joints is a synthetic lithium complex capable of maintaining viscosity in extreme cold. Standard grease can solidify, causing the needle bearings to skid rather than roll, leading to immediate failure. O Eixo da caixa de engrenagens de transferência russa FAW ensures that lubrication is effective from the first turn of the wheel, providing reliable propulsion in the harshest environments.

The steel alloy used for the yokes and tube of the Eixo da caixa de engrenagens de transferência russa FAW is also selected for its impact toughness at low temperatures. Standard carbon steel becomes brittle in the deep freeze; the FAW specification ensures the shaft can withstand the sudden torque shock of a wheel regaining traction without shattering. This material science is what makes the Eixo da caixa de engrenagens de transferência russa FAW a true heavy-duty component.

Divisão de Componentes: 124. Transfer Case Driveshaft

| Não. |

Número da peça |

Nome da peça |

Quantidade |

| 1 | 2215010-55R | Eixo de transmissão da caixa de transferência e conjunto de junta universal | 1 |

| 2 | 2205050-896 | Spline Shaft Yoke and Universal Joint Assembly | 1 |

| 3 | 2205060-896 | Middle Axle Driveshaft and Universal Joint Sub-assembly | 1 |

| 4 | 2205030B761 | Cross Shaft and Needle Roller Bearing Assembly | 2 |

| 5 | 2205041-A0M | Anel de encaixe (Various Sizes) | 8 |

| 6 | 2205081-A0M | Balance Sheet (Vários pesos) | As Req |

| 7 | 2205020-896 | Spline Shaft Yoke Assembly | 1 |

| 8 | CQ70001 | Bico de graxa reto | 1 |

| 9 | 2205015-896 | Middle Axle Driveshaft Tube, Welded Yoke and Spline Sleeve Assembly | 1 |

| 10 | 2205071-A0M | Balance Sheet (Vários pesos) | As Req |

Conclusão: The Link to Arctic Mobility

O Eixo da caixa de engrenagens de transferência russa FAW assembly is the definitive link between the transfer case and the drive axles. Its robust construction, featuring cold-weather seals, specialized grease, and precision balancing, ensures that the CA3250P66K24L1TE5Z can deliver reliable power in the most extreme environments. Cada componente, from the smallest snap ring to the massive tubular shaft, is engineered for durability.

Para gerentes de frota, a manutenção do Eixo da caixa de engrenagens de transferência russa FAW é crítico. Regular greasing of the U-joints and inspection of the balance weights can prevent costly vibration-related failures. Utilizando peças de reposição genuínas FAW, operators ensure that their trucks maintain the factory-engineered balance and strength required to conquer the frozen roads of the Russian North.

Embalagem e Logística

Peças FAW, incluindo o conjunto do bloco de cilindros, são embalados com cuidado para garantir uma entrega segura. Cada componente é protegido por materiais de proteção para evitar danos durante o transporte. A rede logística garante envios pontuais em todo o mundo, apoiando operações de manutenção eficientes. Abaixo está uma imagem ilustrando a embalagem padrão para peças de caminhão FAW, mostrando a atenção aos detalhes no manuseio e armazenamento.

Esta abordagem de embalagem minimiza o risco de corrosão ou danos por impacto, garantindo que peças como o conjunto do bloco de cilindros FAW cheguem em perfeitas condições. Os clientes podem confiar na logística da FAW para obter qualidade e confiabilidade consistentes.