Vidro da janela traseira russa FAW: A blindagem óptica de 2 componentes para visibilidade traseira e isolamento

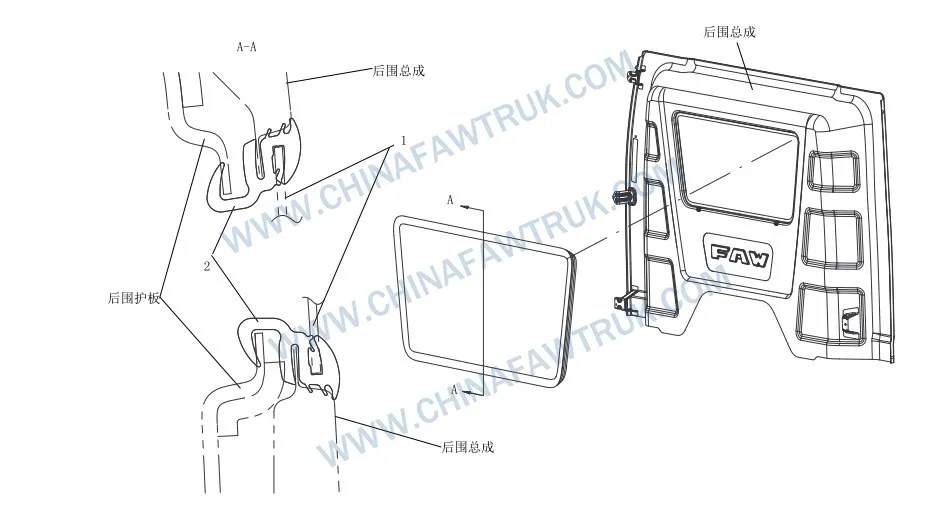

O Vidro da janela traseira russa FAW assembly serves as the vital visual link between the driver and the dump body of the CA3250P66K24L1TE5Z truck. No setor de mineração, maintaining a clear view of the load and the area behind the cab is critical for safety. Esta montagem, comprising a specialized tempered glass pane and a cold-resistant sealing strip, ensures that the cabin remains sealed against the arctic elements while providing distortion-free visibility.

Vidro da janela traseira russa FAW

| Não. |

Número da peça |

Nome da peça |

Quantidade |

| 1 | 5603026-A86 | Rear Window Glass | 1 |

| 2 | 5603038-A86-C00 | Sealing Strip – Rear Window Glass | 1 |

Tempered Safety Glass Technology

O Vidro da janela traseira russa FAW is manufactured using an advanced tempering process. O Rear Window Glass (Parte não. 5603026-A86) is heated to near its softening point and then rapidly cooled. This induces compressive stresses on the surface and tensile stresses within the core. This physical state makes the glass up to five times stronger than standard annealed glass. In the context of a dump truck, this strength is vital for resisting the impact of rocks that may spill over the cab protector during loading operations.

The safety characteristics of the Vidro da janela traseira russa FAW are designed to protect the driver. If the impact energy exceeds the glass’s limit, o Rear Window Glass shatters into thousands of small, blunt granules rather than large, jagged shards. This disintegration pattern minimizes the risk of laceration injuries to the occupants. In the remote mining regions of Russia, where medical assistance may be hours away, this passive safety feature is a critical component of the vehicle’s design philosophy.

Optical clarity is maintained through precision float glass manufacturing. O Rear Window Glass must provide a distortion-free view of the dump bed and the area directly behind the cab. Distortion can lead to misjudging the distance of the load or unseen obstacles during reversing maneuvers. O Vidro da janela traseira russa FAW undergoes rigorous quality control to ensure that the driver sees a true representation of the environment, which is essential for safe maneuvering in tight loading zones.

O “A86” designation in the part number often refers to the tint or light transmission properties. O Vidro da janela traseira russa FAW likely features a specific green or grey tint designed to filter UV radiation and reduce solar heat gain. No verão ártico, where the sun can shine for 20 horas por dia, reducing glare and heat buildup inside the cab helps maintain a comfortable working environment for the driver, reducing fatigue and eye strain.

Cold-Weather Sealing Performance

The effectiveness of the Vidro da janela traseira russa FAW relies heavily on its mounting system. O Sealing Strip – Rear Window Glass (Parte não. 5603038-A86-C00) is engineered specifically for the “Zona Fria” ambiente. O “C00” suffix indicates a specialized rubber compound, likely an EPDM formulation, that retains its flexibility at temperatures as low as -50°C. Standard rubber seals turn brittle and shrink in such cold, creating gaps that allow freezing air and moisture to penetrate the cabin.

This sealing strip utilizes a multi-lip profile to grip both the Rear Window Glass and the steel flange of the cab’s rear wall. The elasticity of the seal accommodates the differential thermal expansion between the glass and the metal bodywork. As the cab heats up from the engine and heater, the metal expands faster than the glass. O Sealing Strip – Rear Window Glass absorbs this movement, preventing stress concentrations that could otherwise cause the glass to crack spontaneously.

Além disso, the seal acts as a vibration damper. A dump truck chassis generates significant low-frequency vibration and high-frequency shock loads on rough haul roads. O Sealing Strip – Rear Window Glass isolates the Rear Window Glass from these forces, preventing the glass from rattling in its frame. This isolation is crucial for longevity; rigid mounting would lead to edge chipping and fatigue failure of the glass pane over time.

The hermetic seal provided by the Vidro da janela traseira russa FAW assembly is also a defense against exhaust fumes. The rear of the cab is a low-pressure zone where exhaust gases can swirl and accumulate. A compromised seal would allow potentially deadly carbon monoxide to seep into the driver’s sleeping or working area. The high-integrity design of the Sealing Strip – Rear Window Glass ensures a gas-tight barrier, maintaining air quality within the cabin.

Thermal Isolation and Anti-Fogging

O Vidro da janela traseira russa FAW plays a significant role in the thermal management of the cabin. While it is a single pane (unlike the double-glazed windscreen), its thickness is optimized to provide a degree of insulation. In the bitter cold, the inner surface of the glass is a prime location for condensation and frost formation. O Rear Window Glass surface quality is smooth to facilitate easy cleaning and minimize the adhesion of ice crystals, allowing the cabin’s heating system to clear the view relatively quickly.

No entanto, the primary thermal break is the Sealing Strip – Rear Window Glass. By preventing cold drafts from entering around the perimeter, the seal allows the HVAC system to maintain a positive pressure of warm air inside the cab. This warm air cushion helps to keep the Vidro da janela traseira russa FAW above the dew point, preventing fogging. In a mining truck where the driver must frequently look back to check the load, a fogged rear window is a major safety hazard.

A integração do Vidro da janela traseira russa FAW with the rear wall insulation panel is seamless. The seal profile is designed to overlap with the interior trim, eliminating cold bridges. This attention to detail ensures that the driver does not feel a chill radiating from the back of the cab, which is particularly important if the vehicle is equipped with a sleeper berth located directly beneath the window.

For extreme conditions, some operators may install aftermarket heating grids, but the standard Vidro da janela traseira russa FAW relies on the efficiency of the cabin’s airflow. The positioning of the air vents in the J6P cab is designed to circulate warm air towards the rear, working in conjunction with the thermal properties of the glass to maintain visibility without the need for active electrical heating elements in the rear pane.

Installation and Replacement Strategy

Substituindo o Vidro da janela traseira russa FAW is a task that requires precision and the correct technique. A montagem usa um “corda” installation method common for heavy trucks. O Sealing Strip – Rear Window Glass is first fitted to the glass, and a cord is inserted into the locking lip. The assembly is then pressed against the aperture, and the cord is pulled to flip the rubber lip over the metal flange. This method avoids the use of chemical adhesives, allowing for quicker replacement in field conditions—a vital consideration for remote mining sites.

It is imperative to use a new Sealing Strip – Rear Window Glass whenever the glass is replaced. Old seals take a “conjunto de compressão” and lose their elasticity. Reusing an old seal on a new Rear Window Glass often leads to leaks, as the rubber cannot conform perfectly to the microscopic variations in the new glass pane. Além disso, an old seal may have micro-cracks from UV exposure that will tear during the installation process.

Fleet managers should ensure that only genuine FAW parts are used. Generic glass may not have the correct “A86” tint or the precise dimensional tolerance required. A Rear Window Glass that is slightly too large creates excessive stress on the cab wall, while one that is too small will not seal properly and may pop out under chassis flex. O genuíno Vidro da janela traseira russa FAW guarantees a perfect fit, maintaining the structural and environmental integrity of the cab.

Before installation, the metal pinch weld on the cab must be inspected for rust or bends. Any corrosion must be treated, as it will spread under the new seal. A interface entre o Sealing Strip – Rear Window Glass and the metal bodywork relies on a smooth, clean surface to be watertight. Taking the time to prep the frame ensures that the Vidro da janela traseira russa FAW will perform flawlessly for years to come.

Conclusão: Visibility and Integrity Combined

O Vidro da janela traseira russa FAW assembly is a deceptively simple system that performs multiple critical functions. Comprising the tempered Rear Window Glass and the specialized Sealing Strip – Rear Window Glass, it provides visibility, insulation, and protection against the elements. Its design is specifically tailored to withstand the rigors of the Russian environment, from extreme cold to rough terrain.

Para operadores de frota, the maintenance of this assembly is essential for safety and driver comfort. Um claro, well-sealed rear window allows the driver to monitor the payload and maneuver safely. By using genuine parts and proper installation techniques, operators ensure that this transparent shield continues to perform its vital role, protecting the driver and the integrity of the vehicle in the harshest conditions.

Embalagem e Logística

Peças FAW, incluindo o conjunto do bloco de cilindros, são embalados com cuidado para garantir uma entrega segura. Cada componente é protegido por materiais de proteção para evitar danos durante o transporte. A rede logística garante envios pontuais em todo o mundo, apoiando operações de manutenção eficientes. Abaixo está uma imagem ilustrando a embalagem padrão para peças de caminhão FAW, mostrando a atenção aos detalhes no manuseio e armazenamento.

Esta abordagem de embalagem minimiza o risco de corrosão ou danos por impacto, garantindo que peças como o conjunto do bloco de cilindros FAW cheguem em perfeitas condições. Os clientes podem confiar na logística da FAW para obter qualidade e confiabilidade consistentes.