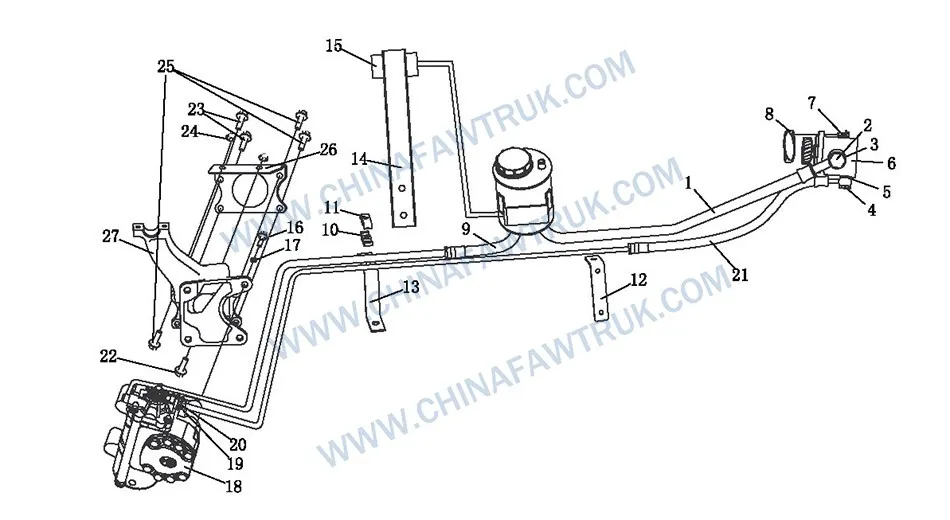

Linha de direção hidráulica FAW russa: Desconstruindo 27 Componentes Críticos para a Precisão do Controle Hidráulico do Ártico

O Linha de direção hidráulica FAW russa represents the essential hydraulic circulatory system for the CA3250P66K24L1TE5Z 6×6 caminhão basculante projetado para operações na Sibéria. This technical breakdown examines the complete power steering fluid network, dissecting it into 27 fundamental serviceable units that ensure reliable hydraulic assistance, fluid integrity, and operational durability in temperatures plunging to -40°C. Our analysis focuses on the specialized hoses, precision fittings, and Arctic-grade materials that maintain flawless hydraulic performance in the demanding Russian mining environment.

Linha de direção hidráulica FAW russa

Primary Fluid Conduits: Inlet and Return Line Assemblies

O Inlet Line Assembly (Parte não. 3406010-55R) serves as the primary supply conduit for hydraulic fluid from the reservoir to the power steering pump. This component in the Linha de direção hidráulica FAW russa system features a multi-layer construction with an inner tube of oil-resistant synthetic rubber, reinforcement layers of braided steel wire, and an outer cover resistant to abrasion, ozônio, e temperaturas extremas. The 55R suffix indicates its Russian Arctic specification, with materials formulated to remain flexible at -50°C, preventing cracking during cold starts in Siberian winter conditions.

Complementando isso é o Montagem da linha de retorno (Parte não. 3406440-55R), which channels fluid back to the reservoir from the steering gear. This low-pressure line operates under different stress conditions than the inlet line, requiring specific design considerations. Para o Linha de direção hidráulica FAW russa, the return line incorporates larger internal diameters to accommodate fluid expansion during temperature fluctuations and features specialized reinforcement that prevents collapse under vacuum conditions during rapid steering maneuvers.

The critical High Pressure Line Assembly (Parte não. 3406030-55R) transmits pressurized fluid from the pump to the steering gear. This component withstands operating pressures exceeding 1500 psi and features six layers of reinforcement, including high-tensile steel braiding and spiral wire wrapping. No Linha de direção hidráulica FAW russa, this assembly undergoes rigorous pressure cycling tests at both extreme high and low temperatures to ensure it maintains integrity throughout the operational range without developing fatigue cracks or weeping connections.

Geração de energia: Pump Assembly and Mounting Components

The heart of the hydraulic system is the Conjunto da bomba de direção hidráulica (Parte não. 3407020-55R-000), a gear-type pump specifically engineered for Arctic operation. This component in the Linha de direção hidráulica FAW russa utilizes materials with matched thermal expansion coefficients to maintain precise internal clearances across temperature extremes. The pump incorporates a flow control valve calibrated for the specific viscosity characteristics of Arctic-grade power steering fluid, ensuring consistent hydraulic pressure regardless of ambient temperature fluctuations.

Mounting the pump securely are the Hexagon Flange Face Bolts – Thick Shank (Tipo padrão) (Parte não. 01841030 e outros). These specialized fasteners provide the clamping force necessary to maintain pump alignment while resisting vibration-induced loosening. Their flange design distributes load over a wider area, preventing distortion of the pump housing. Para o Linha de direção hidráulica FAW russa, these bolts receive additional surface treatments to resist corrosion from road salts and hydraulic fluid exposure, ensuring long-term retention of proper torque specifications.

Ensuring a leak-free interface between the pump and its mounting surface is the Selo – Power Steering Pump (Parte não. 3407024-26D). This specialized gasket is manufactured from nitrile rubber compounded with low-temperature plasticizers that maintain compression set resistance in extreme cold. No contexto do Linha de direção hidráulica FAW russa, this seal undergoes accelerated aging tests to verify it maintains sealing integrity for the expected service life of the vehicle, preventing fluid leaks that could lead to pump cavitation and steering assist failure.

Steering Gear Integration: Assembly and Connection Components

O Power Steering Gear and Limit Pin Assembly (Parte não. 3411010A50A) represents the hydraulic-to-mechanical conversion unit within the Linha de direção hidráulica FAW russa. This integral gearbox contains precision-machined valves that direct hydraulic pressure to assist steering effort based on input torque and vehicle speed. The assembly incorporates wear-resistant materials in high-friction areas and undergoes specialized run-in procedures to ensure smooth operation from initial installation through the vehicle’s service life in demanding conditions.

Connecting hydraulic lines to the steering gear is the Conector – Power Steering Gear (Parte não. 3406024A50A). This forged steel component provides the transition between flexible hoses and the rigid ports of the steering gear. Its design incorporates specific angles and orientations to ensure proper hose routing without sharp bends that could restrict flow or create stress concentration points. Para o Linha de direção hidráulica FAW russa, this connector’s threads are precision-rolled rather than cut, creating superior fatigue resistance to withstand pressure pulsations over millions of steering cycles.

Supporting the steering gear is the Steering Gear Bracket (Parte não. 3403016-99C), which provides rigid mounting to the vehicle frame while allowing for precise alignment adjustments. This structural component in the Linha de direção hidráulica FAW russa system is designed with strategic ribbing and gusseting to withstand the torsional loads generated during off-road operation while maintaining dimensional stability. The 99C designation indicates enhanced corrosion protection suitable for the saline environments encountered in Russian winter road maintenance.

Connection Systems: Hollow Bolts and Sealing Washers

O Parafusos ocos (Parte não. 3406021-74A e 3406021-91) serve as critical junction points within the Linha de direção hidráulica FAW russa, allowing fluid passage through fastening points. These specialized bolts feature precisely machined internal passages that maintain laminar fluid flow while providing secure mechanical connections. Their design includes specific shoulder dimensions that control compression of sealing elements, preventing overtightening that could damage mating surfaces or restrict fluid passages in the hydraulic system.

Creating leak-proof seals at these connections are the Combined Sealing Washers (Parte não. 3406321-74A and 3406321ABE). These composite washers feature a steel outer ring that provides structural support and an inner elastomeric sealing element that conforms to surface imperfections. Para o Linha de direção hidráulica FAW russa, these washers utilize hydrogenated nitrile rubber (HNBR) for the sealing element, which maintains elasticity and compression recovery at temperatures as low as -50°C, ensuring consistent sealing performance throughout Arctic temperature cycles.

Additional fastening security is provided by Hexagon Head Flange Lock Nuts (Parte não. C032616) e Arruelas de pressão (Parte não. 040320). These components work in conjunction to maintain proper clamping force despite vibration and thermal cycling. No Linha de direção hidráulica FAW russa, the lock nuts feature nylon inserts that create prevailing torque, while the spring washers provide constant tension that compensates for minor settling of components, ensuring connections remain secure throughout the vehicle’s operational life.

Support and Routing: Colchetes, Grampos, and Mounting Systems

Proper hose routing is essential in the Linha de direção hidráulica FAW russa, achieved through various Line Brackets (Parte não. 3406112-66S and 3406113-55R). These steel brackets secure hydraulic lines at specific intervals, preventing excessive movement that could lead to abrasion or fatigue failure. Their designs incorporate radiused edges and cushioning materials where lines contact the bracket, eliminating potential wear points that could compromise hose integrity during long-term operation in vibrating environments.

O Double Pipe Clip Seat (Parte não. 3406029-36Z) e Double Pipe Clip Cover (Parte não. 3406028-36Z) work together to secure parallel fluid lines. This system maintains precise spacing between lines, preventing contact that could cause wear through friction during vehicle operation. Para o Linha de direção hidráulica FAW russa, these clips are manufactured from stainless steel to resist corrosion from road chemicals while maintaining clamping force throughout temperature extremes encountered in Russian operations.

Structural support is provided by the Suporte Traseiro – Assembléia de suporte (Parte não. 3408022-55R) e Front Bracket – Assembléia de suporte (Parte não. 3408021A50A). These welded assemblies distribute load across multiple mounting points on the vehicle frame, isolating the Linha de direção hidráulica FAW russa components from frame flexing during off-road operation. Their designs include vibration-damping bushings that absorb high-frequency vibrations from the engine and drivetrain, protecting sensitive hydraulic components from fatigue failure.

Arctic Adaptation: Engenharia de desempenho em climas frios

Cada componente do Linha de direção hidráulica FAW russa is engineered for cryogenic performance. Standard hydraulic hose materials become rigid and prone to cracking below -20°C, but the specialized compounds used here maintain flexibility down to -50°C. This is achieved through advanced polymer formulations that incorporate low-temperature plasticizers and flexible backbone chains that resist glass transition even in extreme cold, ensuring the system remains operational during the critical initial minutes of cold starts in Siberian winters.

Metallic components undergo specialized treatments to prevent brittle fracture. The various Colchetes e Supports receive normalizing heat treatments that refine grain structure and relieve internal stresses that could initiate cracks under impact loading in cold conditions. Para o Linha de direção hidráulica FAW russa, these metallurgical processes ensure components maintain their designed strength and ductility characteristics throughout the operational temperature range, from the heat of engine operation to the extreme cold of Arctic nights.

Corrosion protection is multi-layered and comprehensive. Components receive phosphate coatings for adhesion promotion, galvanoplastia para proteção sacrificial, and powder coat finishes for mechanical and chemical resistance. Essa abordagem no Linha de direção hidráulica FAW russa combate o ambiente altamente corrosivo criado pelos sais rodoviários, agentes descongelantes de cloreto de cálcio, e poluentes industriais encontrados nas operações de mineração e transporte russas, ensuring long-term reliability despite constant exposure to corrosive elements.

Divisão de Componentes: Power Steering Lines

| Não. |

Número da peça |

Nome da peça |

Quantidade |

| 1 | 3406010-55R | Inlet line assembly | 1 |

| 2 | 3406021-74A | Parafuso oco | 1 |

| 3 | 3406321-74A | Combined sealing washer | 2 |

| 4 | 3406021-91 | Parafuso oco | 2 |

| 5 | 3406321ABE | Combined sealing washer | 1 |

| 6 | 3407020-55R-000 | Power steering pump assembly (desenho de estilo) | 1 |

| 7 | 01841030 | Hexagon flange face bolt – thick shank (tipo padrão) | 2 |

| 8 | 3407024-26D | Selo – bomba de direção hidráulica | 1 |

| 9 | 3406440-55R | Return line assembly | 1 |

| 11 | 3406028-36Z | Double pipe clip cover | 1 |

| 12 | 3406112-66S | Line bracket | 1 |

| 13 | 3406113-55R | Line bracket | 1 |

| 14 | 3408022-55R | Rear bracket – support assembly | 1 |

| 15 | 3408021A50A | Front bracket – support assembly | 1 |

| 16 | C01512050T | Hexagon head pilot bolt | 4 |

| 17 | 040320 | Arruela elástica | 4 |

| 18 | 3411010A50A | Power steering gear and limit pin assembly | 1 |

| 19 | 3406321ABE | Combined sealing washer | 4 |

| 20 | 3406024A50A | Conector – power steering gear | 1 |

| 21 | 3406030-55R | High pressure line assembly | 1 |

| 22 | 01841645T | Hexagon flange face bolt – thick shank (tipo padrão) | 1 |

| 23 | 01841660T | Hexagon flange face bolt – thick shank (tipo padrão) | 2 |

| 24 | C032616 | Porca de fixação flangeada com cabeça hexagonal | 5 |

| 25 | 01841650T | Hexagon flange face bolt – thick shank (tipo padrão) | 3 |

| 26 | 3403011-99C | Suporte | 1 |

| 27 | 3403016-99C | Steering gear bracket | 1 |

| 10 | 3406029-36Z | Double pipe clip seat | 1 |

Conclusão: The Hydraulic Control Network

O Linha de direção hidráulica FAW russa represents a sophisticated hydraulic network engineered for reliability and precision in the world’s most demanding environments. From the high-pressure Conjunto da bomba de direção hidráulica to the precisely routed High Pressure Line Assembly and supporting Line Brackets, each of the twenty-seven detailed components contributes to a system that delivers consistent hydraulic assistance regardless of temperature extremes or operational demands. This network ensures precise vehicle control, reduced driver fatigue, and operational safety for heavy dump trucks navigating challenging Arctic terrain.

Understanding the complete breakdown of the power steering hydraulic system empowers maintenance teams to perform targeted inspections and preventative maintenance. Cumprimento dos números de peça especificados, such as the Arctic-grade 3406010-55R inlet line and critical Combined Sealing Washers (3406321ABE), garante o Linha de direção hidráulica FAW russa mantém o desempenho e a confiabilidade projetados durante toda a vida útil do veículo. Para operadores em condições russas extremas, this system is not merely a collection of hoses and fittings; it is the vital hydraulic circulatory system that translates minimal driver effort into precise vehicle control, carga após carga exigente nas operações de mineração mais desafiadoras do mundo.

Embalagem e Logística

Peças FAW, incluindo o conjunto do bloco de cilindros, são embalados com cuidado para garantir uma entrega segura. Cada componente é protegido por materiais de proteção para evitar danos durante o transporte. A rede logística garante envios pontuais em todo o mundo, apoiando operações de manutenção eficientes. Abaixo está uma imagem ilustrando a embalagem padrão para peças de caminhão FAW, mostrando a atenção aos detalhes no manuseio e armazenamento.

Esta abordagem de embalagem minimiza o risco de corrosão ou danos por impacto, garantindo que peças como o conjunto do bloco de cilindros FAW cheguem em perfeitas condições. Os clientes podem confiar na logística da FAW para obter qualidade e confiabilidade consistentes.