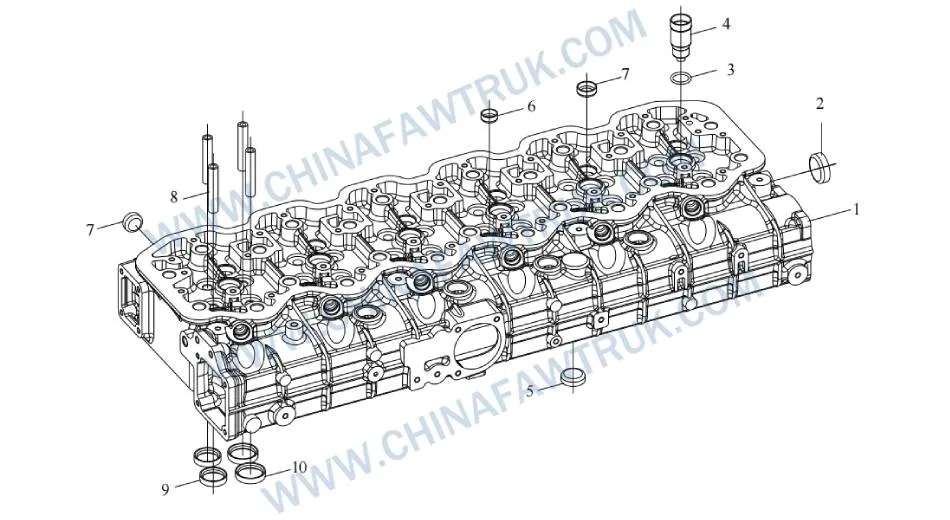

The FAW Cylinder Head represents a critical component in the high-performance CA3250P66K2L1T1E 6×4 dump truck engine manufactured by FAW Jiefang. This comprehensive exploded view guide provides an intricate breakdown of the cylinder head assembly, systematically disassembling the main casting and integrated components down to the smallest serviceable repair units. Our detailed analysis covers both versions – with and without engine brake compatibility – permettant aux techniciens de maintenance d'identifier, service, et remplacez les composants individuels avec précision. Understanding the complete FAW Cylinder Head architecture is essential for optimal combustion efficiency, valve timing accuracy, and overall engine performance in demanding heavy-duty applications.

Disassembling the FAW Cylinder Head requires a systematic approach that begins with removing external components and progresses to internal valve train elements. The process involves carefully separating the main casting from its integrated components, s'assurer que chaque pièce peut être inspectée individuellement, entretenu, ou remplacé. Key disassembly stages include removing valve covers, rocker arms, injecteurs, and eventually accessing the valve seats and guides.

The FAW Cylinder Head design incorporates both standard and engine brake compatible versions, each requiring specific attention during disassembly. The modular construction allows for efficient breakdown without compromising the integrity of the main casting. Cette approche réduit considérablement le temps et les coûts de réparation en permettant un remplacement ciblé des composants plutôt qu'un remplacement complet de l'assemblage..

Proper disassembly of the FAW Cylinder Head ensures that critical components like valve seats, guides, and injector sleeves can be thoroughly inspected for wear or damage. Suivre précisément le schéma de la vue éclatée et se référer à la liste détaillée des pièces garantit une identification précise et une manipulation correcte de chaque composant tout au long du processus de maintenance..

This comprehensive parts list for the FAW Cylinder Head details every component visible in the exploded view diagram. Chaque pièce est identifiée par son numéro de pièce officiel, description, et quantité nécessaire pour l'assemblage complet. Cette référence permet une identification précise, commande, et remplacement de composants individuels pendant les procédures de maintenance.

| Référence | Numéro de pièce | Nom de la pièce | Quantité |

|---|---|---|---|

| 1 | 1003011A59D (1003011-630-000Z) |

Cylinder Head (avec frein moteur) | 1 |

| 1 | 1003011-59D (1003011B630-000Z) |

Cylinder Head (sans frein moteur) | 1 |

| 2 | Q72240 | Bouchon en forme de bol | 1 |

| 3 | 1003018-29D (1003018C29d) |

Joint torique | 6 |

| 4 | 1003016-29D (1003016A29D) |

Fuel Injector Steel Sleeve | 6 |

| 5 | Q72232 | Bouchon en forme de bol (avec frein moteur) | 1 |

| 6 | Q72222 | Bouchon en forme de bol | 6 |

| 7 | Q72226 | Bouchon en forme de bol | 16 |

| 8 | 1003014-29D (1003014M29D) |

Valve Guide | 24 |

| 9 | 1003013-36D | Exhaust Valve Seat | 12 |

| 10 | 1003012-36D | Intake Valve Seat | 12 |

This detailed FAW Cylinder Head parts list serves as an essential reference for maintenance operations. Chaque composant est conçu selon des spécifications précises, garantissant des performances fiables dans les conditions exigeantes typiques des applications de camions-bennes lourds. Lors de la commande de pièces de rechange, always verify part numbers against this official list to guarantee compatibility and optimal performance of your FAW Cylinder Head assembly.

The FAW Cylinder Head for the CA3250P66K2L1T1E model incorporates advanced engineering features designed specifically for heavy-duty applications. Les paramètres techniques suivants fournissent des informations essentielles pour une installation correcte, entretien, et vérification de compatibilité. These specifications ensure the FAW Cylinder Head meets the rigorous demands of construction and mining operations where reliability is paramount.

| Paramètre | spécification |

|---|---|

| Modèle de véhicule | CA3250P66K2L1T1E |

| Configuration du moteur | 6-Cylindre en ligne diesel |

| Head Material | High-Strength Cast Iron Alloy |

| Valve Configuration | 4 Soupapes par cylindre |

| Total Valves | 24 |

| Injector Sleeves | 6 (One per Cylinder) |

| Combustion Chamber Design | Direct Injection Optimized |

| Cooling Passage Design | Cross-Flow Cooling |

| Poids | Environ 85 kg |

| Engine Brake Compatibility | Available in Two Versions |

| Valve Seat Material | Heat-Resistant Steel Alloy |

| Valve Guide Material | Bronze Alloy |

These technical specifications demonstrate the robust construction and engineering excellence of the FAW Cylinder Head. Designed to withstand extreme operating conditions and high combustion pressures, the FAW Cylinder Head ensures reliable performance throughout its service life. Un entretien régulier selon ces paramètres maximisera la durabilité et minimisera les temps d'arrêt pour les opérations de vos camions FAW..

Proper maintenance of the FAW Cylinder Head is crucial for ensuring optimal engine performance and longevity in your CA3250P66K2L1T1E dump truck. Commencez par des inspections visuelles régulières pour vérifier la présence de fissures, déformation, ou des dommages superficiels, particularly around combustion chambers, valve seats, and injector sleeves. Utilisez le schéma de la vue éclatée comme référence lors du démontage pour garantir une identification et une manipulation correctes des composants..

When servicing the FAW Cylinder Head, pay special attention to valve guides and seats, which require precise installation and proper sealing. Le 24 valve guides must be properly seated to ensure optimal valve alignment and minimal wear. De la même manière, intake and exhaust valve seats should be inspected for proper sealing and replaced if any signs of burning or pitting are detected.

Regular inspection and replacement of sealing components like O-rings and bowl shape plugs is essential for preventing coolant and compression leaks in the FAW Cylinder Head assembly. Fuel injector steel sleeves must be carefully installed to ensure proper fuel spray patterns and prevent combustion gas leakage. Always use genuine FAW replacement parts and follow manufacturer torque specifications during reassembly to maintain the structural integrity and performance of your FAW Cylinder Head.

The FAW Cylinder Head offers numerous advantages that contribute to the overall performance and efficiency of FAW trucks. Its robust construction using high-strength cast iron alloy provides exceptional resistance to thermal stress and mechanical loads, garantir un fonctionnement fiable dans les conditions les plus exigeantes. The four-valve per cylinder design optimizes airflow for improved combustion efficiency and power output.

Precision-engineered components within the FAW Cylinder Head assembly, such as the bronze alloy valve guides and heat-resistant steel valve seats, ensure optimal valve operation and extended service life under high-temperature conditions. Cette ingénierie de précision se traduit par une efficacité énergétique améliorée, réduction des émissions, and consistent performance across the engine’s operational range.

The availability of both standard and engine brake compatible versions of the FAW Cylinder Head provides flexibility for different operational requirements. The comprehensive parts availability and detailed documentation further enhance the maintainability of the FAW Cylinder Head, making it an excellent choice for fleet operators seeking reliability, performance, and cost-effective operation in heavy-duty applications.