Welcome to this critical safety and structural analysis of the FAW Rear Mudguard Logic Assembly (Assembly 707). This is the complete, 16-component-type, heavy-duty “splash and spray” suppression system for the FAW Jiefang CA4251P66K24T1A3E5 6×4 diesel semi-trailer tractor. This is not a cosmetic accessory; it is a primary “logic” assembly with a critical three-part function:

1. Protection Logic: To shield the chassis, ‘Air Tank’ (Assembly 393), and ‘Brake Chamber’ (Assembly 419) from a high-velocity “sandblast” of rocks, water, salt, and road debris.

2. Safety Logic: To suppress “road spray” (atomized water) from the drive axles, which is a legal requirement in many regions to prevent blinding other motorists.

The FAW Rear Mudguard Logic Assembly is an engineered system of “structural” and “sacrificial” components. The “logic” is to create a rigid, vibration-proof steel “skeleton” (the ‘Support Frames’ and ‘Brackets’) that then holds the large, “sacrificial” polymer ‘Mudguard’ panels. This modularity is key to a low cost of ownership.

This in-depth guide is essential for fleet managers, body shop technicians, and parts specialists. We will deconstruct the entire FAW Rear Mudguard Logic Assembly into its 16 distinct component types. We will analyze the “structural skeleton” logic (frames, supports, bases), the “protection skin” logic (the mudguards and deflectors), and the massive 62-piece “anti-vibration” fastener system.

The foundation of the FAW Rear Mudguard Logic Assembly is its “skeleton.” This is a 7-piece, modular, heavy-duty steel framework that anchors the entire assembly to the truck’s chassis rails. This is the “longer” and most critical part of the system.

1. The “Main Frame” Logic (Component 3):

The ‘Rear mudguard fixed support frame welded assy’ (5103505-91W) is the “backbone” of the assembly. The list calls for four (4) of these. The “welded assy” (焊接总成) logic means this is a fabricated, high-strength steel component.

This component’s “logic” is to be the primary “anchor.” It bolts directly to the truck’s chassis frame (using fasteners 12 & 13) and acts as the main load-bearing “arm” that cantilevers *out* over the dual-drive axles. It is designed to be immensely rigid, resisting the constant “flapping” (vibration) of the mudguard.

2. The “Sub-Frame” Logic (Components 4 & 5):

The ‘Left/Right rear mudguard support’ (5103391-91W / 5103392-91W) are the secondary “logic” components. These are the *vertical* supports. Their “logic” is to bolt to the *end* of the ‘Main Frame’ (Component 3), providing the vertical mounting “face” that the ‘Mudguard’ panels (Components 1 & 2) actually attach to. This “sub-frame” logic creates a strong, modular “T” shape.

3. The “Anchor Base” Logic (Components 6 & 7):

The ‘Left/Right rear mudguard support fixed base’ (5103373-91W / 5103374-91W) are the “chassis-side” anchors. The “logic” of these components is to be the “mating flange.” They are the heavy-duty steel plates that bolt *to the chassis rail*. The ‘Main Frame’ (Component 3) then bolts *to this base*.

This “modular” logic is for serviceability. In a collision, if the main arm (Component 3) is bent, the technician can unbolt it from this “Base” (Component 6/7) and replace it, without having to re-align a new bracket to the chassis frame itself. This entire 7-part (4+1+1+1) “skeleton” is the core of the FAW Rear Mudguard Logic Assembly.

This group of components is the “sacrificial skin” of the FAW Rear Mudguard Logic Assembly. These are the parts designed to take the impact and be replaced.

Components 1 & 2: ‘Left/Right rear mudguard’ (5103361-50A / 5103362-50A): These are the main “mudguard” panels. Their “logic” is to be a massive “shield.” They are molded from a durable, flexible, high-impact polymer. This “material logic” is key: they are flexible enough to “flap” without breaking, strong enough to deflect rocks, and 100% corrosion-proof.

Components 15 & 16: ‘…Anti-spray deflector’ (5103381-54B / 5103382-54B): This is the “Safety Logic.” These “deflectors” are the “brush” or “astroturf” style strips that hang from the mudguard’s edge. Their “logic” is to *suppress spray*. They “catch” the fine, atomized mist of water and let it “drip” rather than “spray,” which is a legal requirement to prevent blinding other drivers.

Component 14: ‘…Upper brace’ (5103466-50A): This is the “rigidity logic” for the plastic. This “brace” is a metal strip that bolts along the *top edge* of the plastic mudguard, preventing it from “sagging” or “warping” over time.

This is the “logic” that holds the FAW Rear Mudguard Logic Assembly together. This system is subjected to the *worst* vibration on the entire vehicle (unsprung mass vibration). A standard fastener system would fail in hours.

Components 8, 9, 11, 12 (‘Combination bolt’): The assembly uses a total of 40 “Combination” (组合) bolts. The “logic” of these bolts is their *captive, pre-attached lock washer* (e.g., a spring or serrated washer). This lock washer “bites” into the steel, providing constant tension that is *immune to vibration*.

Components 10 & 13 (‘Hexagon nut’): The assembly uses a total of 30 “Nuts” to complete the “logic.” These are “prevailing-torque” (Nyloc) lock nuts. Their “logic” is a nylon insert that *grips* the bolt threads.

This “dual-fastener” logic (a lock washer on the bolt + a lock nut on the other end) creates a “failsafe” connection that *cannot* vibrate loose. This is why all 16 of these components are critical, “single-use” serviceable parts. Re-using a lock nut is a critical safety failure, as it will lead to the FAW Rear Mudguard Logic Assembly detaching from the vehicle.

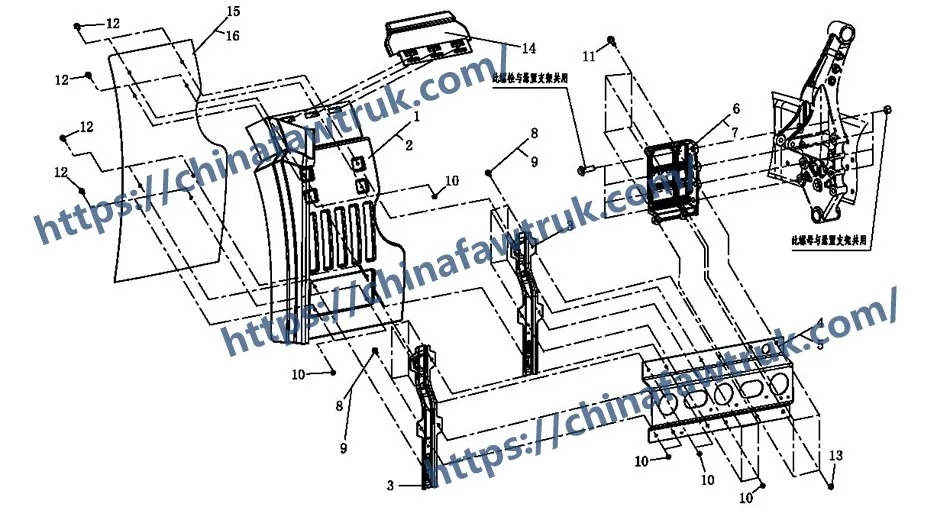

The following table provides the complete, detailed breakdown of all 16 component types identified in the FAW Rear Mudguard Logic Assembly for the FAW CA4251P66K24T1A3E5 tractor.

| Mark | Part No. | Part Name | Quantity |

|---|---|---|---|

| 1 | 5103361-50A | Left rear mudguard | 1 |

| 2 | 5103362-50A | Right rear mudguard (see 5103361-50A) | 1 |

| 3 | 5103505-91W | Rear mudguard fixed support frame welded assy | 4 |

| 4 | 5103391-91W | Left rear mudguard support | 1 |

| 5 | 5103392-91W | Right rear mudguard support | 1 |

| 6 | 5103373-91W | Left rear mudguard support fixed base | 1 |

| 7 | 5103374-91W | Right rear mudguard support fixed base | 1 |

| 8 | CQ1460820 | Combination bolt | 8 |

| 9 | CQ1460825 | Combination bolt | 8 |

| 10 | CQ34008 | Hexagon nut | 22 |

| 11 | CQ1461035 | Combination bolt | 8 |

| 12 | CQ1460820B | Combination bolt | 16 |

| 13 | CQ34010 | Hexagon nut | 8 |

| 14 | 5103466-50A | Rear mudguard upper brace | 2 |

| 15 | 5103381-54B | Left rear mudguard anti-spray deflector | 1 |

| 16 | 5103382-54B | Right rear mudguard anti-spray deflector (see 5103381-54B) | 1 |

The specifications for the FAW Rear Mudguard Logic Assembly are defined by its function as a safety-critical, modular “splash and spray” suppression system.

| Vehicle Application | FAW Jiefang CA4251P66K24T1A3E5 6×4 Tractor |

| Component Group | FAW Rear Mudguard Logic Assembly |

| System Type | Modular Splash Guard & Spray Suppression System |

| Primary Logic | Debris & Water Shield (Chassis Protection) |

| Secondary Logic | Safety (Spray Suppression), NVH (Anti-Vibration) |

| Panel Components | Polymer Mudguards (L/R), Anti-Spray Deflectors (L/R) |

| Structural Components | Welded Support Frames (x4), Supports (L/R), Fixed Bases (L/R) |

| Total Fastener Count | 62 (40 Combination Bolts, 22 Hex Nuts) |

| Fastener Logic | Anti-Vibration (Combination Bolts & Lock Nuts) |

| Serviceability | High: All 16 component types are individual serviceable parts. |

FAW parts, including the Cylinder Block Assembly, are packaged with care to ensure safe delivery. Each component is secured in protective materials to prevent damage during transit. The logistics network guarantees timely shipments worldwide, supporting efficient maintenance operations. Below is an image illustrating the standard packaging for FAW truck parts, showcasing the attention to detail in handling and storage.

This packaging approach minimizes the risk of corrosion or impact damage, ensuring that parts like the FAW Cylinder Block Assembly arrive in perfect condition. Customers can rely on FAW’s logistics for consistent quality and reliability.