Welcome to this in-depth technical analysis of the FAW Logic Assembly for Independent Air-Heated Heating System (Assembly 717). This is the complete, 12-component-type, “fuel delivery” system for the cab’s “bunk heater” on the FAW Jiefang CA4251P66K24T1A3E5 6×4 tractor. This is a critical “comfort and anti-idle” logic assembly, designed to provide the fuel source for the ‘Automatic A/C’ (Assembly 710) and its “independent cold/warm air” function.

The “logic” of the FAW Logic Assembly for Independent Air-Heated Heating System is to safely and precisely deliver diesel fuel from the truck’s main tank to the heater’s combustion chamber. This “no-idle” logic is essential for driver comfort (allowing all-night heat without running the main engine), fuel savings, and compliance with anti-idling laws.

This expert guide is a vital resource for HVAC technicians and parts managers. We will deconstruct this entire FAW Logic Assembly for Independent Air-Heated Heating System into its 12 serviceable component types. We will analyze the “metering” logic of the ‘Fuel Pump’ (Component 4), the “arterial” logic of the ‘Fuel Pipes’ (Components 7 & 12), the “anti-leak” logic of the 12-piece clamp/hose kit, and the “anti-chafe” logic of the routing hardware.

The “heart” of the FAW Logic Assembly for Independent Air-Heated Heating System is the ‘Fuel pump assy’ (8115580-81U). This is the primary “active” component in this kit.

1. The “Dosing” Logic (Component 4):

This is *not* a high-volume pump like the engine’s main fuel pump. This is a low-volume, high-precision “dosing” or “metering” pump. Its “logic” is to deliver a tiny, precise, *pulsed* amount of fuel (e.g., 0.1mL per “click”).

This “dosing” logic is how the heater *controls its temperature*. The ‘A/C operating mechanism’ (Assembly 710) does not control the *flame* directly; it controls the *speed* of this pump.

When the driver sets the thermostat to “high,” the “logic” is that the A/C brain sends a *fast* pulse signal (e.g., 5 “clicks” per second) to this pump. When the driver sets it to “low,” the brain sends a *slow* pulse (e.g., 1 “click” per second). This “metering” logic is the key to a stable, efficient, and smoke-free burn.

2. The “Electrical” Logic (Component 6):

The ‘Fuel pump harness assy – whole vehicle’ (8115640-96S) is the “nervous system” for the pump. This component’s “logic” is to provide a “plug-and-play” connection. It connects the pump’s “pulse” input to the main ‘A/C harness’ (710) and provides a safe, chassis-grounded connection.

3. The “NVH” Logic (Component 5):

A “dosing” pump is a “percussive” device; it makes a loud “CLICK-CLICK-CLICK” noise. This noise, if bolted directly to the chassis, would “telegraph” through the metal frame and be heard in the cab, driving a sleeping driver insane.

The ‘Fuel pump fixing hoop assy’ (8115585-81U) is the “anti-NVH” (Noise, Vibration, Harshness) logic. This component is a rubber-lined, “isolation” mount. Its “logic” is to “float” the pump, with the soft rubber absorbing the “click” vibration, preventing it from ever reaching the chassis.

This group of components is the “plumbing” of the FAW Logic Assembly for Independent Air-Heated Heating System.

The “Arteries” (Components 7 & 12): ‘Fuel pipe A’ (8115561-62U) and ‘Fuel pipe B’ (8115562-96S) are the main transport lines.

The “Joints” (Components 1, 2, 3): This is the “anti-leak” and “anti-vibration” logic. This kit includes *four* “soft connections” (1x ‘Right-angle’, 3x ‘Standard’) and *eight* ‘Clamps’.

The “logic” is that the ‘Fuel Pipes’ (7 & 12) are rigid nylon, but the ‘Fuel Pump’ (4) is “soft-mounted” in a rubber hoop. These “soft connections” (flexible EPDM rubber joints) are the “flex points” that absorb the vibration between the engine and chassis, preventing the rigid lines from cracking. The ‘Clamps’ (Component 3) provide the 360-degree, “air-tight” sealing force. An air leak *into* the “supply” logic is a primary cause of heater flame-out.

This final group of components is the “installation” logic for the FAW Logic Assembly for Independent Air-Heated Heating System.

Components 8, 9, 10 (Structural Mount): This 3-piece kit (‘Combination bolt’, ‘Large washer’, ‘Hexagon nut’) is the “anchor logic” for the *pump*.

The ‘Combination bolt’ (CQ1460835) is the “anti-vibration” logic, with its captive lock washer. The ‘Large washer’ (Q40208) is the “polymer-safe” logic, distributing the load on the rubber ‘Fixing hoop’ (Component 5). The ‘Hexagon nut’ (CQ34008) is the “Nyloc” (self-locking) nut, providing a “failsafe” anti-vibration grip.

Component 11: ‘Plastic retaining strap’ (T67427946) – Qty 6: This is the “anti-chafe” logic. These 6 straps (zip-ties) are critical serviceable parts. Their “logic” is to securely fasten the ‘Fuel pipes’ (7 & 12) and ‘Harness’ (6) *away* from hot/moving components (like the driveshaft or exhaust). A missing strap is the #1 cause of a “rub-through” fuel line leak, which is a critical fire hazard.

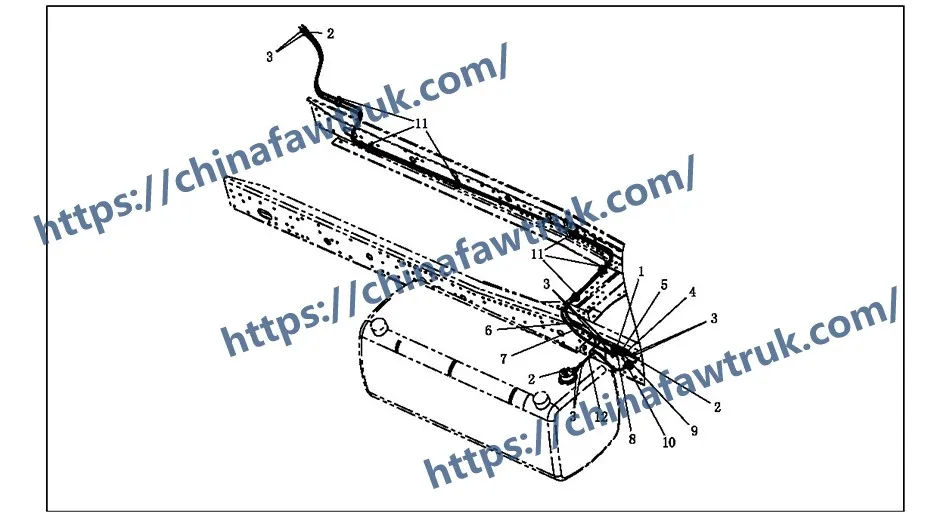

The following table provides the complete, detailed breakdown of all 12 component types identified in the FAW Logic Assembly for Independent Air-Heated Heating System for the FAW CA4251P66K24T1A3E5 tractor.

| Mark | Part No. | Part Name | Quantity |

|---|---|---|---|

| 1 | 8115598-62U | Right-angle soft connection | 1 |

| 2 | 8115596-B82 | Standard soft connection | 3 |

| 3 | 8115595-B82 | Clamp | 8 |

| 4 | 8115580-81U | Fuel pump assy | 1 |

| 5 | 8115585-81U | Fuel pump fixing hoop assy | 1 |

| 6 | 8115640-96S | Fuel pump harness assy – whole vehicle | 1 |

| 7 | 8115562-96S | Fuel pipe B | 1 |

| 8 | CQ1460835 | Combination bolt | 1 |

| 9 | Q40208 | Large washer | 1 |

| 10 | CQ34008 | Hexagon nut | 1 |

| 11 | T67427946 | Plastic retaining strap | 6 |

| 12 | 8115561-62U | Fuel pipe A | 1 |

The specifications for the FAW Logic Assembly for Independent Air-Heated Heating System are defined by its function as a precision, “no-idle” fuel delivery system.

| Vehicle Application | FAW Jiefang CA4251P66K24T1A3E5 6×4 Tractor |

| Component Group | FAW Logic Assembly for Independent Air-Heated Heating System |

| System Type | Independent Heater Fuel Delivery System |

| Primary Logic | Pulsed “Dosing” of Diesel Fuel for No-Idle Heat |

| Secondary Logic | NVH (Pump Isolation), Anti-Chafe (Routing), Anti-Leak (Clamps) |

| Component 1 (Pump) | ‘Fuel pump assy’ (8115580-81U) |

| Component 2 (Pipes) | ‘Fuel pipe A’ (8115561-62U) & ‘Fuel pipe B’ (8115562-96S) |

| Component 3 (Mounts) | ‘Fuel pump fixing hoop assy’ (8115585-81U) |

| Component 4 (Harness) | ‘Fuel pump harness assy’ (8115640-96S) |

| Sealing System | 4x ‘Soft connection’, 8x ‘Clamps’ |

| Routing System | 6x ‘Plastic retaining strap’ (T67427946) |

FAW parts, including the Cylinder Block Assembly, are packaged with care to ensure safe delivery. Each component is secured in protective materials to prevent damage during transit. The logistics network guarantees timely shipments worldwide, supporting efficient maintenance operations. Below is an image illustrating the standard packaging for FAW truck parts, showcasing the attention to detail in handling and storage.

This packaging approach minimizes the risk of corrosion or impact damage, ensuring that parts like the FAW Cylinder Block Assembly arrive in perfect condition. Customers can rely on FAW’s logistics for consistent quality and reliability.