Welcome to this in-depth analysis of the FAW Gearshift Guard (Assembly 693). This is the complete, 3-component-type, “center console” assembly for the FAW Jiefang CA4251P66K24T1A3E5 6×4 diesel semi-trailer tractor. This component is a critical Human-Machine Interface (HMI) that serves a “dual-logic” purpose: it is the primary “aesthetic and ergonomic” hub for the driver, and it is a “functional” module that integrates storage and HVAC components.

The FAW Gearshift Guard is the main structural and cosmetic console that bridges the ‘Dashboard Components’ (Assembly 647) to the cab’s floor. Its “logic” is to provide a clean, “automotive-grade” finish that conceals the gear shift linkage, seals the cab floor, and provides mounting points for the ‘Gearshift guard storage box’ (5305021-B27) and the controls for the 2KW independent heater.

This expert guide is essential for cab technicians, parts specialists, and fleet managers. We will deconstruct the entire FAW Gearshift Guard assembly into its 3 distinct Minimum Serviceable Unit (MSU) types. We will analyze the “HMI and NVH logic” of the main ‘Guard’ (MSU 1), the “ergonomic logic” of the ‘Storage Box’ (MSU 2), and the critical “anti-vibration” logic of the ‘Combination screw’ (MSU 3) fastener system.

The ‘Gearshift guard’ (5305011-B27) is the primary MSU of the FAW Gearshift Guard assembly. This is the main “skin” or “center console” structure. Its “logic” is a complex blend of ergonomics, aesthetics, and function.

1. The “Aesthetic & HMI” Logic:

This is the “driver-facing” logic. This component is the main console that bridges the dashboard to the floor, wrapping around the gear shifter. It is a large, 3D-molded component made from a durable, scuff-resistant polymer (like ABS or TPO).

Its “logic” is to provide a clean, “automotive-grade” interior and to act as the HMI “hub.” This panel provides the main cutout for the gear shift lever boot (sold separately) and the mounting points for the ‘Gearshift guard storage box’ (MSU 2). It presents all these components to the driver in a single, ergonomic, and easy-to-reach “pod.”

2. The “NVH & Sealing” Logic:

This FAW Gearshift Guard is a critical “Noise, Vibration, and Harshness” (NVH) component. The gear shifter linkage passes through a large hole in the cab’s metal floor. This hole is a direct pathway for noise, heat, and vibration from the transmission.

This MSU’s “logic” is to act as the final “acoustic cover.” It works *with* the ‘Floor Carpet’ (Assembly 692) and ‘Soundproofing Pad’ (Assembly 623) to “cap” this hole. The rigid, “acoustically-dead” polymer, often backed with a fibrous mat, “logic” is to *absorb* in-cab noise (like the radio) and *block* low-frequency “drone” and “whine” from the transmission and driveshaft. It also acts as a “thermal break,” blocking heat from the transmission tunnel from radiating onto the driver’s legs.

3. The “Service & Sub-Model” Logic:

This component (5305011-B27) is a key MSU for service. Technicians must remove this ‘Gearshift guard’ to access the gear shift linkage, tower, air lines, and any electrical sensors on the transmission.

The assembly’s title (“…with independent heater”) is a critical “logic” clue. This specific FAW Gearshift Guard is molded with a *dedicated vent* or “cutout” for the 2KW independent heater (bunk heater) controls and hot air outlet. This “integration logic” makes it a specific part for high-spec sleeper cabs, as a base-model truck would use a different, “blank” guard.

The ‘Gearshift guard storage box’ (5305021-B27) is the second key MSU of the FAW Gearshift Guard assembly. This is the “ergonomic” part of the system.

Functional Logic: The “logic” of this component is to provide “at-hand,” convenient storage for the driver’s daily-use items. It is designed to hold logbooks, pens, sunglasses, or a phone. This “ergonomic logic” prevents the driver from having to reach for items, improving safety.

Modular Logic: This “storage box” is a separate MSU, not molded as one piece with the main ‘Guard’. This “modular logic” is for manufacturing efficiency and serviceability. It is easier to mold two simple parts than one highly complex part. It also means that if a driver breaks *only* the storage box, they can replace this single, cheaper MSU (5305021-B27) without needing to replace the entire FAW Gearshift Guard assembly.

The final MSU is the ‘Cross recessed flat round head combination screw’ (Q2360616F6). The parts list calls for three (3) of these.

Fastening Logic: This is the “fastening logic” for the assembly. The small quantity (3) means these are *not* the only fasteners; the main guard (MSU 1) is certainly held to the floor by other clips and bolts. The “logic” of these *three* screws is to *combine* the two main MSUs: they are used to secure the ‘Storage Box’ (MSU 2) to the ‘Gearshift guard’ (MSU 1).

Combination “Logic”: The most critical “logic” is the word “Combination” (组合). This is not a standard screw. It is an MSU that has a *captive, pre-attached lock washer* (e.g., a serrated or spring washer) under its head.

A dashboard/console is the #1 source of cab rattles. A standard screw *will* vibrate loose. This “anti-vibration” logic is essential. The lock washer provides constant tension, “biting” into the mounting brackets and guaranteeing a silent, rattle-free installation for the life of the FAW Gearshift Guard.

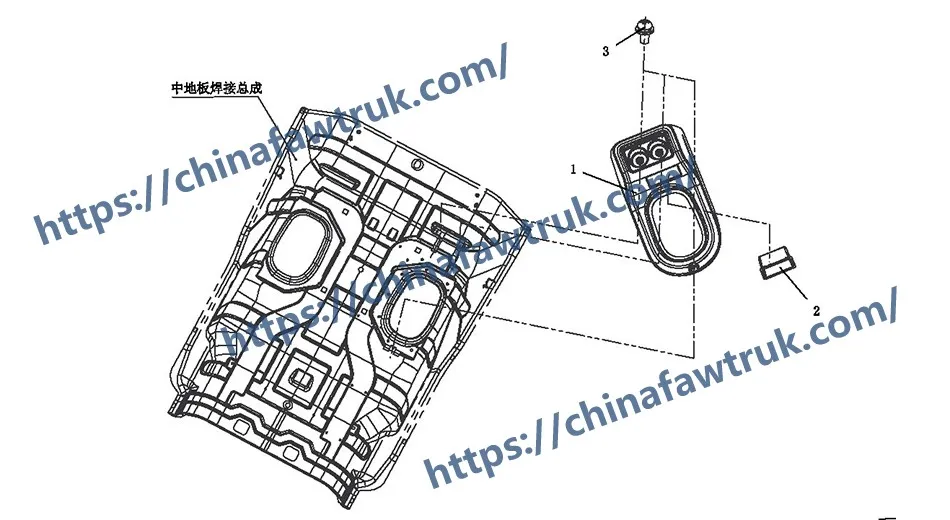

The following table provides the complete, detailed breakdown of all 3 component types identified in the FAW Gearshift Guard assembly for the FAW CA4251P66K24T1A3E5 tractor.

| Mark | Part No. | Part Name | Quantity |

|---|---|---|---|

| 1 | 5305011-B27 | Gearshift guard | 1 |

| 2 | 5305021-B27 | Gearshift guard storage box | 1 |

| 3 | Q2360616F6 | Cross recessed flat round head combination screw | 3 |

The specifications for the FAW Gearshift Guard are defined by its function as a modular, multi-functional interior console for the cab.

| Vehicle Application | FAW Jiefang CA4251P66K24T1A3E5 6×4 Tractor |

| Component Group | FAW Gearshift Guard |

| System Type | Center Console / Shifter Bezel Assembly |

| Primary Logic | HMI (Driver Interface), Aesthetic (Finishing) |

| Secondary Logic | NVH (Acoustic/Thermal/Vibration Damping) |

| Function | Covers shift linkage, integrates storage & heater controls |

| Material | High-Impact, Textured Polymer (ABS/TPO) |

| MSU 1 (Guard) | ‘Gearshift guard’ (5305011-B27) |

| MSU 2 (Storage) | ‘Gearshift guard storage box’ (5305021-B27) |

| MSU 3 (Fasteners) | ‘…combination screw’ (Q2360616F6) – Qty 3 |

| Fastener Logic | Anti-Vibration (Captive Lock Washer) for modular assembly. |

FAW parts, including the Cylinder Block Assembly, are packaged with care to ensure safe delivery. Each component is secured in protective materials to prevent damage during transit. The logistics network guarantees timely shipments worldwide, supporting efficient maintenance operations. Below is an image illustrating the standard packaging for FAW truck parts, showcasing the attention to detail in handling and storage.

This packaging approach minimizes the risk of corrosion or impact damage, ensuring that parts like the FAW Cylinder Block Assembly arrive in perfect condition. Customers can rely on FAW’s logistics for consistent quality and reliability.