Welcome to this critical technical guide on the FAW Front Combination Lamp Logic Assembly (Assembly 560). This is the complete, multi-part, serviceable headlight and signaling unit for the FAW Jiefang CA4251P66K24T1A3E5 6×4 diesel semi-trailer tractor. This assembly is the “face” of the vehicle, defining its aesthetics and providing all critical forward-facing illumination.

The FAW Front Combination Lamp Logic Assembly is a “logic” system with two main purposes: “to see” and “to be seen.” It is not a single bulb, but a complex, integrated housing that combines multiple light sources, precision-engineered reflectors or projectors, and a durable, aerodynamic lens. Its logic is to provide optimal, legally-compliant illumination for low beams, high beams, and turn signals in one sealed unit.

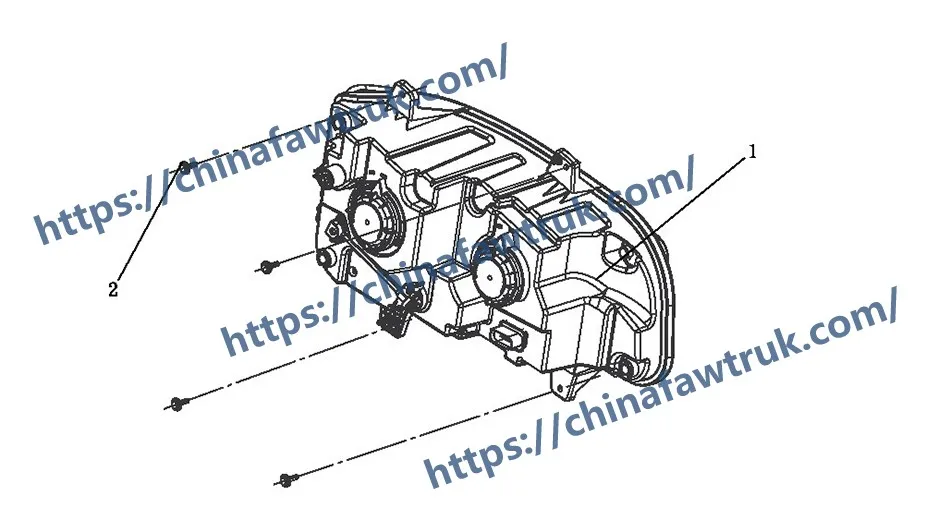

This in-depth guide is an essential resource for professional technicians, fleet managers, and parts specialists. We will deconstruct the entire FAW Front Combination Lamp Logic Assembly into its 3 core serviceable components as listed: the ‘Left front combination lamp assembly’ (3711015-91W-C00), the ‘Right front combination lamp assembly’ (3711020-91W-C00), and the ‘Combination bolt’ (CQ1460625) fasteners that secure them.

The main components of this system are the ‘Left front combination lamp assembly’ (3711015-91W-C00) and the ‘Right front combination lamp assembly’ (3711020-91W-C00). These are the two complete “headlight” units. They are designed as mirror images of each other and are the most prominent feature of the truck’s front end.

The “combination” logic is the key design feature. In older vehicles, each function (headlight, turn signal, parking light) was a separate, individual lamp. The modern FAW Front Combination Lamp Logic Assembly integrates all of these functions into a single, aerodynamically efficient, and sealed unit. This simplifies manufacturing, reduces drag, and provides a clean, modern aesthetic.

Each of these assemblies contains several distinct “logic” circuits:

These assemblies are built to be durable. The outer “lens” is not glass, but a high-impact, shatter-resistant polycarbonate. This lens is “hard-coated” to resist scratches and UV-coated to prevent the “yellowing” and “fogging” that plagued older plastic headlights. The entire unit is hermetically sealed with a butyl rubber sealant to prevent any moisture or dust from entering. A “foggy” or water-filled headlight assembly is a failed assembly.

The “logic” inside the FAW Front Combination Lamp Logic Assembly is a marvel of optical engineering. A simple bulb (like an H4 or H7 halogen bulb) blasts light in 360 degrees. This is useless for driving. The assembly’s “logic” is to capture and focus this light.

This is done using a **complex-surface reflector**. The “chrome” bowl behind the bulb is not a simple-parabolic shape. It is a series of dozens of small, computer-designed facets, each one calculated to catch a specific ray of light and direct it to a precise spot on the road. This is what creates the sharp “cut-off” for the low beam.

The most critical “logic” for any headlight replacement is **aiming**. A new headlight assembly is not “plug-and-play.” It must be aimed. If it is aimed too low, the driver will not be able to see far enough ahead. If it is aimed too high, it will blind oncoming drivers, creating a severe safety hazard. The FAW Front Combination Lamp Logic Assembly is equipped with (unlisted, but integral) adjustment screws. These screws allow a technician to precisely adjust the vertical (up/down) and horizontal (left/right) aim of the beam, ensuring it meets all legal and safety requirements.

The final component of the FAW Front Combination Lamp Logic Assembly is the ‘Combination Bolt’ (CQ1460625). The parts list calls for eight of these (four for each headlight assembly). These are the critical fasteners that secure the entire assembly to the truck’s body or radiator support structure.

The “logic” of a **”Combination Bolt” (组合螺栓)** is a key feature for both manufacturing speed and service reliability. This is not just a standard bolt. It is a pre-assembled fastener that has a captive (non-removable) spring washer and a captive flat washer already attached to its shaft.

This design is critical for two reasons:

These eight bolts provide the rigid, three-point (or four-point) mounting that the headlight needs to maintain its precise aim, even after thousands of miles on rough roads.

The following table provides the complete, detailed breakdown of all 3 components identified in the ‘Front Combination Lamp Logic Assembly’ (560) diagram for the FAW CA4251P66K24T1A3E5 tractor.

| Mark | Part No. | Part Name | Quantity |

|---|---|---|---|

| 1 | 3711015-91W-C00 | Left front combination lamp assembly | 1 |

| 3711020-91W-C00 | Right front combination lamp assembly | 1 | |

| 2 | CQ1460625 | Combination Bolt | 8 |

The specifications for the FAW Front Combination Lamp Logic Assembly are defined by its function as a multi-light, sealed, and aimable unit. The FAW Front Combination Lamp Logic Assembly is a key safety and compliance component.

| Vehicle Application | FAW Jiefang CA4251P66K24T1A3E5 6×4 Tractor |

| Component Group | FAW Front Combination Lamp Logic Assembly |

| Main Assembly P/N (Left) | 3711015-91W-C00 |

| Main Assembly P/N (Right) | 3711020-91W-C00 |

| System Type | Multi-function “Combination” Light |

| Main Functions | Low Beam Headlight, High Beam Headlight, Turn Signal, Position Lamp |

| Optical Logic | High-precision Complex-Surface Reflector or Projector |

| Lens Material | Polycarbonate (UV and scratch-resistant) |

| Sealing | Hermetically sealed (water and dust-proof) | Example

| Mounting Hardware | 8x ‘Combination Bolts’ (CQ1460625) with captive lock washers |

FAW parts, including the Cylinder Block Assembly, are packaged with care to ensure safe delivery. Each component is secured in protective materials to prevent damage during transit. The logistics network guarantees timely shipments worldwide, supporting efficient maintenance operations. Below is an image illustrating the standard packaging for FAW truck parts, showcasing the attention to detail in handling and storage.

This packaging approach minimizes the risk of corrosion or impact damage, ensuring that parts like the FAW Cylinder Block Assembly arrive in perfect condition. Customers can rely on FAW’s logistics for consistent quality and reliability.