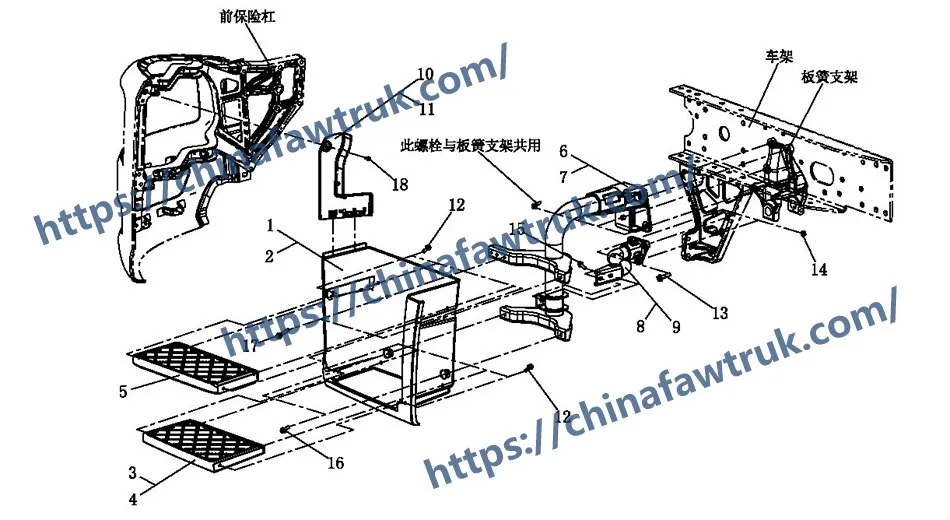

Welcome to this in-depth analysis of the FAW First And Second Step Assemblies With Decorative Covers (Assembly 705). This is the complete, 18-component-type, “ingress/egress” system for the FAW Jiefang CA4251P66K24T1A3E5 6×4 diesel semi-trailer tractor. This is a primary driver safety and ergonomic assembly. Its “logic” is to provide a robust, non-slip, and multi-level “staircase” for safe cab access, while also serving as an aerodynamic and aesthetic body panel.

The FAW First And Second Step Assemblies With Decorative Covers system is a “dual-logic” design. Its first “logic” is structural: a set of heavy-duty ‘Support Arm’ components (5103225-91W, etc.) bolt directly to the cab’s ‘Welded Assembly’ (617) to provide a load-bearing foundation. Its second “logic” is a modular, “sacrificial” design. The ‘Step Panels’ (5103031-91W, etc.) and ‘Decorative Covers’ (5103021-91W, etc.) are individual, replaceable polymer parts.

This modular “logic” is critical for reducing repair costs. This in-depth guide is an essential resource for collision repair specialists and parts managers. We will deconstruct the entire FAW First And Second Step Assemblies With Decorative Covers system into its 18 distinct serviceable component types. We will analyze the “structural logic” of the 4 support arms, the “safety logic” of the step panels, the “aero logic” of the trim, and the 7-type “anti-vibration” fastener system.

The foundation of the FAW First And Second Step Assemblies With Decorative Covers is its “skeleton.” This is a set of four (4) massive, load-bearing support arms that act as the structural “chassis” for the entire system.

1. The “Logic” of the Main Arms (Components 6 & 7):

The ‘Left/Right step panel support arm assy’ (5103225-91W / 5103230-91W) are the primary structural components. Their “logic” is to be the main load-bearing cantilevers.

These are not simple brackets; they are heavy-duty, fabricated (welded) steel assemblies, designed to withstand the entire weight of a driver (plus gear) bouncing on the steps. This “load-bearing” logic is critical for driver safety. These arms bolt directly to the ‘Welded Cab Assembly’ (617) structural frame and serve as the main, rigid foundation for the ‘Second-level step panel’ (Component 5).

2. The “Logic” of the Front Arms (Components 8 & 9):

The ‘Left/Right step panel front support arm assy’ (5103325-91W / 5103330-91W) are the secondary structural components. Their “logic” is “stabilization.”

While the main arms (6 & 7) provide the primary vertical support, these “front” arms provide the “anti-twist” (torsional) rigidity. They create a “triangulated” support system, preventing the ‘First-level step panel’ (Component 3 & 4) from flexing, vibrating, or “flapping” at highway speeds. This “anti-vibration” logic is key to the system’s longevity and “rattle-free” performance.

These four arms form the complete “sub-frame” for the FAW First And Second Step Assemblies With Decorative Covers. In a collision, these are the primary serviceable parts that are inspected for bends or cracked welds.

This group of components is the “user-facing” part of the FAW First And Second Step Assemblies With Decorative Covers. This is the “staircase” for the driver.

Components 3 & 4: ‘Left/Right first-level step panel’ (5103031-91W / 5103032-91W)

Component 5: ‘Second-level step panel’ (5103033-91W) – Qty 2

The “logic” of these 3 parts (totaling 4 pieces) is “Safety & Durability.” They are molded from a heavy-duty, high-impact, UV-stabilized polymer.

Non-Slip Logic: The “safety logic” is the aggressive, raised “tread” pattern on the surface. This is not for looks; it is an “anti-slip” design. This tread is engineered to provide maximum boot grip, even when covered in mud, snow, ice, or diesel fuel. This is the #1 design feature for preventing driver slips and falls.

“Pass-Through” Logic: The tread is often an “open-grid” design. This “logic” allows mud, snow, and gravel to “pass through” the step, rather than building up and creating a slippery hazard.

Modular Logic: The “logic” of this being three separate part numbers is “serviceability.” These panels are the highest-wear, highest-impact items. If a driver damages the ‘Left first-level step’, they only need to replace that single, “sacrificial” component, not the entire FAW First And Second Step Assemblies With Decorative Covers.

This group of MSUs from the FAW First And Second Step Assemblies With Decorative Covers provides the final “fit and finish.”

Components 1 & 2: ‘Left/Right step panel decorative cover’ (5103021-91W / 5103022-91W)

These are the “A-panels,” the main cosmetic “skins” that are visible from the side. Their “logic” is to hide the ‘Support Arms’ (6-9) and fasteners, providing a smooth, “automotive-grade” finish. This “aero logic” also reduces wind drag and noise.

Components 10 & 11: ‘Step panel left/right upper trim’ (5103061-91W / 5103062-91W)

This is the “finishing” logic. These trim pieces are the “gaskets” or “seals” that “logic” is to bridge the gap between the ‘Step Panel’ (3-5) and the cab’s metal body. They provide a clean, finished edge and block “wind whistle” (NVH).

This final group is the “logic” of anti-vibration, essential for the FAW First And Second Step Assemblies With Decorative Covers. This system uses a massive 38-piece, 7-type fastener kit.

Components 12, 13, 15, 16, 17 (‘Combination bolt’): The “logic” of these 34 bolts is “anti-vibration.” They *all* have a pre-attached, captive *lock washer*. This “logic” provides constant tension, guaranteeing that the 4 structural arms and 4 step panels *cannot* vibrate loose.

Component 14 (‘Hexagon nut’): These 6 nuts are the “anchor logic,” used to secure the bolts that pass *through* the chassis frame.

Component 18 (‘…screw, spring washer and plain washer assy’): This 2-piece set is the “polymer-safe” logic. It is a “combination” screw *and* a “plain washer.” This “logic” is used to fasten the ‘Decorative Trim’ (10 & 11) to the plastic panels, using the washer to distribute the load and prevent cracking.

The following table provides the complete, detailed breakdown of all 18 component types identified in the FAW First And Second Step Assemblies With Decorative Covers for the FAW CA4251P66K24T1A3E5 tractor.

| Mark | Part No. | Part Name | Quantity |

|---|---|---|---|

| 1 | 5103021-91W | Left step panel decorative cover | 1 |

| 2 | 5103022-91W | Right step panel decorative cover | 1 |

| 3 | 5103031-91W | Left first-level step panel | 1 |

| 4 | 5103032-91W | Right first-level step panel | 1 |

| 5 | 5103033-91W | Second-level step panel | 2 |

| 6 | 5103225-91W | Left step panel support arm assy | 1 |

| 7 | 5103230-91W | Right step panel support arm assy | 1 |

| 8 | 5103325-91W | Left step panel front support arm assy | 1 |

| 9 | 5103330-91W | Right step panel front support arm assy | 1 |

| 10 | 5103061-91W | Step panel left upper trim | 1 |

| 11 | 5103062-91W | Step panel right upper trim | 1 |

| 12 | CQ1460825F6B | Combination bolt | 16 |

| 13 | CQ1461045 | Combination bolt | 6 |

| 14 | CQ34010 | Hexagon nut | 6 |

| 15 | CQ1460820 | Combination bolt | 4 |

| 16 | CQ1460820F6B | Combination bolt | 4 |

| 17 | CQ1460845F6B | Combination bolt | 4 |

| 18 | Q2360620F6B | Cross recessed pan head screw, spring washer and plain washer assy | 2 |

The specifications for the FAW First And Second Step Assemblies With Decorative Covers are defined by its function as a multi-component, structural, and ergonomic driver access system.

| Vehicle Application | FAW Jiefang CA4251P66K24T1A3E5 6×4 Tractor |

| Component Group | FAW First And Second Step Assemblies With Decorative Covers |

| System Type | Modular Cab Access Step & Trim System |

| Primary Logic | Driver Safety (3-Point Contact, Non-Slip) |

| Secondary Logic | Structural Support, Aerodynamic Fairing, NVH (Anti-Rattle) |

| Component 1 (Frame) | 4x Welded Steel Support Arms (Left/Right, Main/Front) |

| Component 2 (Steps) | 4x Polymer Step Panels (Level 1 L/R, Level 2 x2) |

| Component 3 (Trim) | 4x Polymer Decorative Covers/Trims (L/R) |

| Fastener System | 38-Piece, 7-Type Anti-Vibration Kit (Combination Bolts, Nuts) |

| Serviceability | High: All 18 component types are individual serviceable parts. |

FAW parts, including the Cylinder Block Assembly, are packaged with care to ensure safe delivery. Each component is secured in protective materials to prevent damage during transit. The logistics network guarantees timely shipments worldwide, supporting efficient maintenance operations. Below is an image illustrating the standard packaging for FAW truck parts, showcasing the attention to detail in handling and storage.

This packaging approach minimizes the risk of corrosion or impact damage, ensuring that parts like the FAW Cylinder Block Assembly arrive in perfect condition. Customers can rely on FAW’s logistics for consistent quality and reliability.