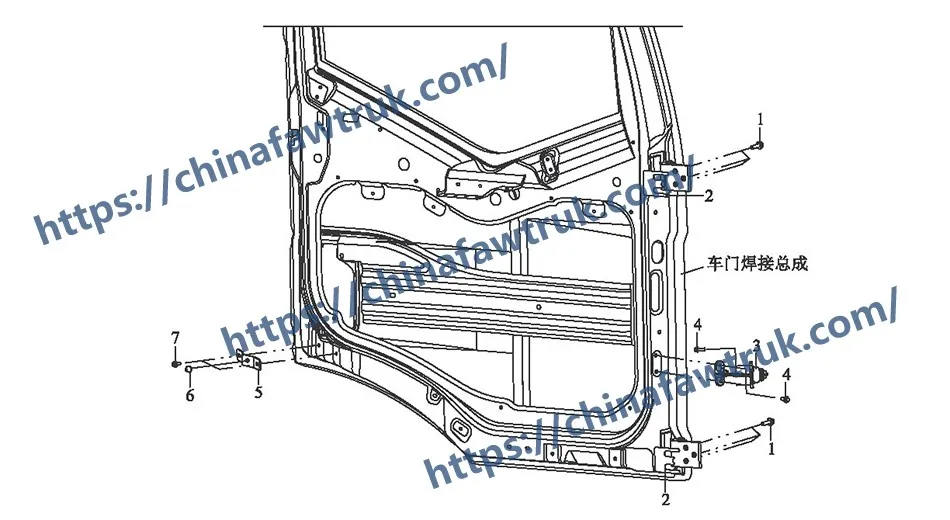

Welcome to this critical safety analysis of the FAW Door Stop assembly (Assembly 690). This is the complete, 7-component-type, heavy-duty “door check” and “limiter” system for the ‘FAW Front Door’ (Assembly 683) on the FAW Jiefang CA4251P66K24T1A3E5 6×4 diesel semi-trailer tractor. This is not a simple strap; it is a critical “logic” assembly with a dual safety function:

1. “Detent” Logic: It holds the heavy cab door *open* at a pre-set angle, preventing it from slamming shut on the driver.

2. “Limiter” Logic: It provides a “hard stop” to prevent the door from “over-extending,” which is critical for preventing catastrophic wind damage.

The FAW Door Stop (or “door check”) is the unsung hero of the cab. A failure of this component can lead to a “free-swinging” door that can be caught by the wind, swinging it open with enough force to bend the ‘Welded Cab Assembly’ (617) A-pillar, shatter the ‘Side Window’ (634), and destroy the door hinges. This small assembly prevents thousands in collision damage.

This in-depth guide is essential for body shop technicians and parts managers. We will deconstruct the entire FAW Door Stop system into its 7 distinct Minimum Serviceable Unit (MSU) types. We will analyze the “detent” logic of the main ‘Stop Assy’ (MSU 3), the “anchor” logic of the brackets (MSU 5), the “damping” logic of the rubber blocks (MSU 6), and the critical “anti-vibration” fastener logic (MSUs 1, 4, 7).

The ‘Front door stop assy’ (6106035-A01) is the heart of the FAW Door Stop system. The list calls for two (2), one for each door. This MSU is a heavy-duty mechanical arm, and it performs two “logic” functions simultaneously.

1. The “Detent” Logic (Hold-Open):

This is the “door check” or “hold-open” logic. This MSU is not just a flat strap. It is a thick steel arm with a precisely shaped profile (with “valleys” and “peaks” stamped into it). Inside the ‘Mounting Bracket’ (MSU 5), which this arm slides through, are a set of powerful spring-loaded rollers or pins.

As the door opens, these rollers “ride” along the arm. When they fall into one of the “valleys” (the detent), the spring pressure “locks” them in place. This is the “click” you feel. This “detent logic” is strong enough to hold the heavy FAW Front Door (683) open, preventing it from swinging shut on the driver’s legs as they climb in or out.

2. The “Limiter” Logic (Anti-Hyperextension):

This is the critical “anti-damage” logic. The FAW Door Stop arm (MSU 3) has a “hard stop” built into its end. This “logic” of a fixed limit physically *prevents* the door from opening too far.

This is arguably the most valuable function of the FAW Door Stop. A heavy truck door, caught by a sudden, strong gust of wind, becomes a “sail.” Without this limiter, the wind would slam the door “open” with incredible force. This force would hyperextend the door hinges, “peeling” the door from the A-pillar, bending the ‘Welded Cab Assembly’ (617) frame, and destroying the door.

This MSU is the “sacrificial” component. It is designed so that, in a catastrophic wind-gust event, this *limiter* will break *before* the cab’s A-pillar does. Replacing a $50 FAW Door Stop is infinitely preferable to a $5,000 structural cab repair.

Serviceability: This MSU is a high-wear item. The detent “valleys” wear down over time, resulting in a “weak” door that won’t stay open. It is a sealed unit (pre-greased) and is replaced as a single assembly.

This group of MSUs forms the “chassis-side” interface for the FAW Door Stop.

MSU 5: ‘…Door Stop Mounting Bracket’ (6101543-A01 / 6101544-A01): This is the “anchor” logic. These are the heavy-duty, fabricated steel brackets (Left & Right) that are securely bolted to the *inside* of the cab’s A-pillar.

The ‘Front Door Stop Assy’ (MSU 3) passes *through* this bracket. This MSU is what contains the “detent” rollers and springs mentioned earlier. Its “logic” is to be the immovable “anchor” that withstands 100% of the pulling force from the door.

MSU 6: ‘…Door Stop Damper Block’ (6101541-A01) – Qty 2: This is the “NVH” (Noise, Vibration, Harshness) logic. These two dense rubber blocks are the “bump stops.”

Their “logic” is to provide a “soft stop.” When the FAW Door Stop (MSU 3) reaches its “limit,” it makes contact with this rubber block. This prevents a harsh, loud “CLANK” of metal-on-metal impact, eliminating noise and reducing the “shock load” on the cab’s frame. A missing damper block will result in a noisy door and will eventually cause the limiter pin to fail.

This final group of MSUs is the hardware. The “logic” of this kit is about “alignment” and “anti-vibration,” which are essential for a functional FAW Door Stop.

MSU 2: ‘Adjustment shim-hinge’ (6106061-A01) – Qty 1: This is the “alignment logic.” This single, thin, precision-cut shim is a critical MSU. Its “logic” is to be placed *between* the ‘Mounting Bracket’ (MSU 5) and the cab’s A-pillar. This allows a body shop technician to minutely “push” or “pull” the bracket’s alignment, changing the angle of the FAW Door Stop. This is essential for ensuring the door opens to the *exact* correct angle and seals perfectly.

MSUs 1, 4, 7 (Bolts): This is the “fastener logic.” The system uses 24 total high-tensile bolts, of two types: ‘Hexagon flange bolts’ (12 total) and ‘Combination bolts’ (12 total).

The “logic” is 100% “anti-vibration.”

Both of these designs provide constant tension on the bolt head. A “door check” is one of the highest-vibration, highest-impact parts on a truck. A standard bolt would shake loose. This “locking fastener” logic is what ensures the FAW Door Stop remains rigidly attached to the cab, providing safe and silent operation.

The following table provides the complete, detailed breakdown of all 7 component types identified in the FAW Door Stop assembly for the FAW CA4251P66K24T1A3E5 tractor.

| Mark | Part No. | Part Name | Quantity |

|---|---|---|---|

| 1 | CQ1461035 | Combination bolt | 12 |

| 2 | 6106061-A01 | Adjustment shim-hinge | 1 |

| 3 | 6106035-A01 | Front door stop assy | 2 |

| 4 | Q1840616F6 | Hexagon flange bolt, coarse thread (standard type) | 8 |

| 5 | 6101543-A01 | Left front door stop mounting bracket | 1 |

| 6101544-A01 | Right front door stop mounting bracket (see 6101543-A01) | 1 | |

| 6 | 6101541-A01 | Front door stop damper block | 2 |

| 7 | Q1840612F6 | Hexagon flange bolt, coarse thread (standard type) | 4 |

The specifications for the FAW Door Stop are defined by its function as a safety-critical, dual-logic door check and limiter system.

| Vehicle Application | FAW Jiefang CA4251P66K24T1A3E5 6×4 Tractor |

| Component Group | FAW Door Stop |

| System Type | Mechanical Door Check (Detent) & Limiter |

| Primary Logic | Damage Prevention (Anti-Hyperextension / Limiter) |

| Secondary Logic | Safety (Hold-Open Detent), NVH (Damper Block) |

| MSU 3 (Arm) | ‘Front door stop assy’ (6106035-A01) – Qty 2 |

| MSU 5 (Anchor) | ‘…Mounting Bracket’ (6101543-A01 / 6101544-A01) |

| MSU 6 (Damper) | ‘…Damper block’ (6101541-A01) – Qty 2 |

| MSU 2 (Align) | ‘Adjustment shim-hinge’ (6106061-A01) – Qty 1 |

| Fastener Logic | Anti-Vibration (Combination & Flange Bolts) |

FAW parts, including the Cylinder Block Assembly, are packaged with care to ensure safe delivery. Each component is secured in protective materials to prevent damage during transit. The logistics network guarantees timely shipments worldwide, supporting efficient maintenance operations. Below is an image illustrating the standard packaging for FAW truck parts, showcasing the attention to detail in handling and storage.

This packaging approach minimizes the risk of corrosion or impact damage, ensuring that parts like the FAW Cylinder Block Assembly arrive in perfect condition. Customers can rely on FAW’s logistics for consistent quality and reliability.