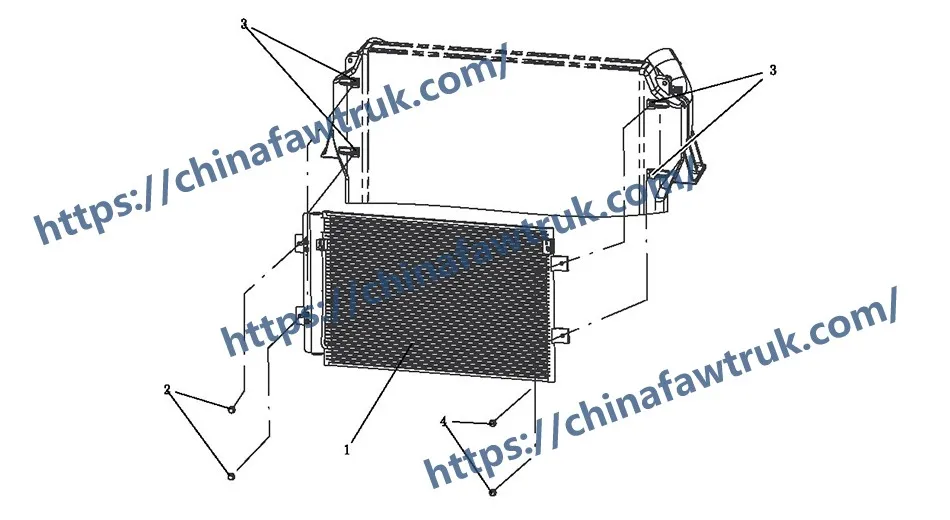

Welcome to this in-depth analysis of the FAW Condenser Unit Logic Assembly (Assembly 714). This is the complete, 4-component-type, “heat exchange” system for the ‘Automatic Air Conditioning’ (Assembly 710) on the FAW Jiefang CA4251P66K24T1A3E5 6×4 diesel semi-trailer tractor. This assembly is the “hot side” of the A/C, a critical “logic” component that is solely responsible for releasing the heat that has been *removed* from the cab.

The “logic” of the FAW Condenser Unit Logic Assembly is to function as a “refrigerant-to-air” radiator. It receives high-pressure, *hot gas* refrigerant from the A/C compressor. As air from the ‘FAW Fan’ (Assembly 711) passes through its fins, it “logic” is to radiate this heat into the atmosphere, causing the refrigerant inside to “condense” into a *cool liquid*. This “phase change” logic is the key to the entire air conditioning cycle.

This expert guide is essential for HVAC technicians and parts managers. We will deconstruct the entire FAW Condenser Unit Logic Assembly into its 4 distinct serviceable component types. We will analyze the “micro-channel” logic of the ‘Condenser assy’ (Component 1) itself, and the critical, 8-piece “dual-lock” fastener system (Components 2, 3, 4) that provides a rock-solid, anti-vibration mount.

The ‘Condenser assy’ (8105010-13A-C00) is the “heart” of the FAW Condenser Unit Logic Assembly. It is the primary serviceable unit and a high-tech “heat exchanger.” Its “logic” is to perform the critical “phase change” of the refrigerant.

1. The “Phase Change” Logic (Gas to Liquid):

The A/C compressor (on the engine) compresses the refrigerant, turning it into a very hot (e.g., 80°C / 176°F), high-pressure *gas*. This hot gas is then piped *into* the ‘Condenser assy’.

The “logic” of the condenser is to act as a “radiator.” As the ‘FAW Fan’ (711) pulls cool, ambient air through the condenser’s fins, this heat is “radiated” away. This “cooling” logic is what causes the high-pressure gas *inside* the condenser tubes to “condense” into a high-pressure, *cool liquid*.

This “phase change” from gas to liquid is the *only* way the A/C system can work. This liquid is then sent to the ‘Evaporator’ (709), where it “expands” back into a gas, becoming intensely cold. Therefore, the “logic” of the FAW Condenser Unit Logic Assembly is to be the “hot side” that makes the “cold side” possible.

2. The “Material & Construction” Logic:

This component is a masterpiece of thermal “logic.” It is constructed entirely from **aluminum**. This “material logic” is chosen because aluminum is lightweight (for fuel economy) and has *extremely high* thermal conductivity (it transfers heat very fast).

The “construction logic” is “micro-channel.” Older condensers used round tubes. This modern FAW Condenser Unit Logic Assembly uses flat, multi-channel “micro-tubes” (like a stack of thin, flat straws).

This “logic” is for efficiency. It creates a *massive* internal surface area for the refrigerant, allowing it to “condense” much faster in a much smaller, lighter package. The “fins” (the wavy aluminum strips) are the “radiation logic,” providing the external surface area for the air to pull the heat away.

3. The “Location & Failure” Logic:

The “logic” of the condenser’s *location* is also its biggest *weakness*. It is mounted *in front of* the main engine radiator. This “logic” ensures it gets the “first hit” of the coldest, fastest-moving air from the grille.

This also means it is the *first* component to be hit by rocks, gravel, insects, and road debris. The #1 failure “logic” for any FAW Condenser Unit Logic Assembly is a *puncture* from a small stone, which allows all the refrigerant to leak out, killing the A/C system.

The second failure “logic” is “clogging.” If the “fins” get “caked” with dirt, leaves, and insects, air cannot pass through. This “clogged” logic prevents the heat from being removed. The pressure inside the A/C system will skyrocket, leading to a “blown” hose or a failed compressor.

As a serviceable part, the ‘Condenser assy’ is a single, non-repairable, sealed unit. It cannot be “patched” (due to high pressure). It must be replaced as a single component.

This group of components is the “installation logic” for the FAW Condenser Unit Logic Assembly. A condenser is a sensitive, lightweight aluminum part, yet it lives in the highest-vibration zone of the truck. The fastener “logic” is designed to create a “dual-lock,” anti-vibration system.

This is an 8-piece system (4 bolts + 4 nuts).

Components 2 & 4: ‘Combination bolt’ (CQ1460820 / CQ1460825) – Qty 4 total

This is the “first lock” logic. A “Combination” (组合) bolt has a *captive, pre-attached lock washer* (e.g., a serrated or spring washer). This “logic” is the primary “anti-vibration” defense. The lock washer “bites” into the condenser’s mounting bracket, providing constant tension that prevents the bolt from backing out.

Component 3: ‘Hexagon nut’ (CQ34008) – Qty 4

This is the “second lock” logic. These are not standard nuts; they are “Nyloc” (nylon insert) or “prevailing-torque” lock nuts. The nylon insert “grips” the threads of the bolt.

This “dual-lock” (a lock washer on the bolt + a lock nut on the end) is a “failsafe” logic. It is an engineering “belt-and-suspenders” approach to ensure that the FAW Condenser Unit Logic Assembly *cannot* vibrate loose, which would cause it to “rattle” against the radiator, leading to a puncture and failure of both components. These fasteners are critical, “single-use” serviceable parts.

The following table provides the complete, detailed breakdown of all 4 component types identified in the FAW Condenser Unit Logic Assembly for the FAW CA4251P66K24T1A3E5 tractor.

| Mark | Part No. | Part Name | Quantity |

|---|---|---|---|

| 1 | 8105010-13A-C00 | Condenser assy | 1 |

| 2 | CQ1460820 | Combination bolt | 2 |

| 3 | CQ34008 | Hexagon nut | 4 |

| 4 | CQ1460825 | Combination bolt | 2 |

The specifications for the FAW Condenser Unit Logic Assembly are defined by its function as the primary “hot-side” heat exchanger for the cab’s A/C system.

| Vehicle Application | FAW Jiefang CA4251P66K24T1A3E5 6×4 Tractor |

| Component Group | FAW Condenser Unit Logic Assembly |

| System Type | A/C Refrigerant-to-Air Heat Exchanger |

| Primary Logic | “Phase Change” (Condensation) of Hot Gas Refrigerant to Cool Liquid |

| Construction | Aluminum “Micro-Channel” Tubes and Fins |

| Location | Front of Radiator / Cooling Stack |

| Component 1 (Core) | ‘Condenser assy’ (8105010-13A-C00) |

| Component 2 (Bolts) | ‘Combination bolt’ (CQ1460820 / CQ1460825) – 4 Total |

| Component 3 (Nuts) | ‘Hexagon nut’ (CQ34008) – 4 Total |

| Fastener Logic | “Dual-Lock” Anti-Vibration (Combination Bolt + Lock Nut) |

| Serviceability | Condenser is a single sealed component. All fasteners are single-use. |

FAW parts, including the Cylinder Block Assembly, are packaged with care to ensure safe delivery. Each component is secured in protective materials to prevent damage during transit. The logistics network guarantees timely shipments worldwide, supporting efficient maintenance operations. Below is an image illustrating the standard packaging for FAW truck parts, showcasing the attention to detail in handling and storage.

This packaging approach minimizes the risk of corrosion or impact damage, ensuring that parts like the FAW Cylinder Block Assembly arrive in perfect condition. Customers can rely on FAW’s logistics for consistent quality and reliability.