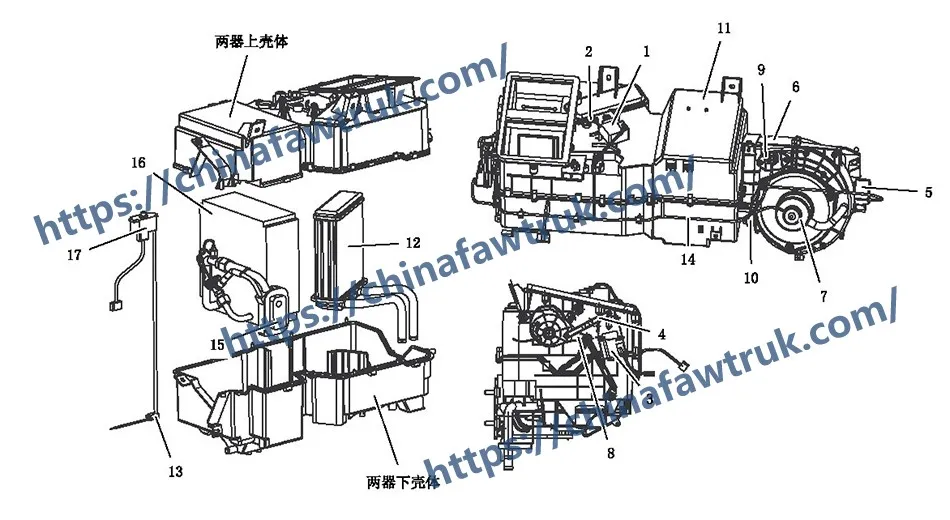

Welcome to this in-depth technical analysis of the FAW Automatic Air Conditioning With Dual-Zone Climate Control (Assembly 709). This is the complete, 17-component-type, “dual-zone” HVAC (Heating, Ventilation, and Air Conditioning) system for the FAW Jiefang CA4251P66K24T1A3E5 6×4 tractor. This is the “logic” core of the cab’s comfort, providing automated climate management for both the driver and the passenger/sleeper areas.

The “dual-zone” logic of the FAW Automatic Air Conditioning With Dual-Zone Climate Control means it is not one simple system. It is a “two-box” (两箱) assembly. This includes the ‘Evaporator assy’ (the “cold” box) and the ‘Heater core assy’ (the “hot” box). Its “automatic” logic comes from a network of sensors (like the ‘In-cab temp sensor’) and modules that automatically blend hot and cold air to maintain a pre-set temperature.

This expert guide is essential for HVAC technicians and parts managers. We will deconstruct the entire FAW Automatic Air Conditioning With Dual-Zone Climate Control system into its 17 serviceable component types. We will analyze the “brain” (the modules/sensors), the “air handlers” (blower/doors), the “cold side” (evaporator), the “hot side” (heater core), and the “nervous system” (the harness).

This is the “brain” and “hands” of the FAW Automatic Air Conditioning With Dual-Zone Climate Control. This group is the “logic” of command and execution, translating the driver’s request into a physical action.

The “Command” Components (HMI):

These are the serviceable parts the driver physically touches. Their “logic” is to send an electrical signal to the “brain” (Component 9).

The “Brain” & “Muscles” (Actuators):

Component 9: ‘Speed control module’ (8101080-A65-C00): This is the “brain” or “resistor pack.” Its “logic” is to manage the speed of the ‘Blower’ (Component 6) fan. In “Auto” mode, this module (not the driver) decides how fast the fan needs to run.

Component 8: ‘Central drive’ (8101051-A65-C00): This is the “muscle.” It is an electric “servo” motor. Its “logic” is to physically move the ‘Cold/warm air door’ (Component 4). When the driver turns the temp dial, this motor is what *blends* the air from the “hot” and “cold” boxes.

Component 4: ‘Cold/warm air door’ (8101025-A65-C00): This is the key “blending” door, a serviceable part that can fail, leading to the system being “stuck on hot” or “stuck on cold.”

This group of components is the “lungs” of the FAW Automatic Air Conditioning With Dual-Zone Climate Control. Its “logic” is to move the air.

Component 6: ‘Blower assy’ (8101040-A65-C00): This is the main “fan” assembly. It is a serviceable unit that contains the motor and the “squirrel cage” fan. Its “logic” is to draw air (either from outside via the ‘Upper Grille’ (637) or from inside the cab) and *force* it through the “cold” and “hot” boxes.

Component 7: ‘Motor with belt wheel assy’ (8101045-A65-C00): This is the motor *for* the blower. A “belt wheel” (pulley) “logic” suggests this is a heavy-duty, belt-driven blower, rather than a direct-drive motor. A common failure point is worn motor “brushes” or a seized bearing, leading to a “dead” or “squealing” fan.

This is the “Air Conditioning” half of the FAW Automatic Air Conditioning With Dual-Zone Climate Control.

Component 16: ‘Evaporator assy’ (8107030-A65-C00): This is the “cold” core. Its “logic” is to be a radiator-in-reverse. Cold, liquid refrigerant is “expanded” inside it, causing it to flash-boil and become *extremely cold*. The ‘Blower’ (Component 6) forces hot cab air *through* this core, and the heat is “sucked” out of the air. This process also *dehumidifies* the air, which is the “anti-fog” logic for the windscreen.

Component 15: ‘Expansion bladder’ (8106010-A65-C00): This is the “logic” valve (also called a TXV or orifice tube) that *causes* the expansion mentioned above. A failure of this component will stop all cooling.

Component 17: ‘Evaporator temp sensor’ (8107080-A65-C00): A critical “logic” sensor. Its job is to tell the “brain” the temperature of the evaporator. If it gets *too cold* (below 0°C), the moisture pulled from the air will *freeze* solid, turning the core into a block of ice and stopping all airflow. This sensor’s “anti-icing” logic tells the A/C compressor to cycle off *before* this freezing happens.

This is the “Heating” and “Sensor” half of the FAW Automatic Air Conditioning With Dual-Zone Climate Control.

Component 12: ‘Heater core assy’ (8101210-A65-C00): This is the “hot” core. Its “logic” is simple: it is a small radiator, plumbed into the engine’s hot coolant (antifreeze) system. Hot coolant flows through it, and the ‘Blower’ (Component 6) forces air through it, transferring the engine’s waste heat into the cab.

The “Logic” Sensors (Components 10, 11, 13): These are the “nerves” of the “Automatic” system.

The final component is the ‘A/C electric harness assy’ (3724090AD04). This is the “nervous system” logic of the FAW Automatic Air Conditioning With Dual-Zone Climate Control.

This single, complex harness is the “logic” that connects all the other components. It is a “plug-and-play” serviceable part that provides the wiring for:

A failure in this harness (a “pinched” wire or a “corroded” connector) can cause “ghost” failures in the FAW Automatic Air Conditioning With Dual-Zone Climate Control system that are notoriously hard to diagnose.

The following table provides the complete, detailed breakdown of all 17 component types identified in the FAW Automatic Air Conditioning With Dual-Zone Climate Control assembly for the FAW CA4251P66K24T1A3E5 tractor.

| Mark | Part No. | Part Name | Quantity |

|---|---|---|---|

| 1 | 8101010-A65-C00 | State switch with lever assy (see 8100015-A65-C00) | 1 |

| 2 | 8101015-A65-C00 | Mode switch with lever (see 8100015-A65-C00) | 1 |

| 3 | 8101020-A65-C00 | Temp switch with lever assy (see 8100015-A65-C00) | 1 |

| 4 | 8101025-A65-C00 | Cold/warm air door (see 8100015-A65-C00) | 1 |

| 5 | 8101030-A65-C00 | Recirculating switch with lever assy (see 8100015-A65-C00) | 1 |

| 6 | 8101040-A65-C00 | Blower assy (see 8100015-A65-C00) | 1 |

| 7 | 8101045-A65-C00 | Motor with belt wheel assy (see 8100015-A65-C00) | 1 |

| 8 | 8101051-A65-C00 | Central drive (see 8100015-A65-C00) | 1 |

| 9 | 8101080-A65-C00 | Speed control module (see 8100015-A65-C00) | 1 |

| 10 | 8101091-A65-C00 | In-cab temp sensor (see 8100015-A65-C00) | 1 |

| 11 | 8101110-A65-C00 | Blower assy (see 8100015-A65-C00) | 1 |

| 12 | 8101210-A65-C00 | Heater core assy (see 8100015-A65-C00) | 1 |

| 13 | 8101241-A65-C00 | Freeze temp sensor (see 8100015-A65-C00) | 2 |

| 14 | 3724090AD04 | A/C electric harness assy | 1 |

| 15 | 8106010-A65-C00 | Expansion bladder assy (see 8100015-A65-C00) | 1 |

| 16 | 8107030-A65-C00 | Evaporator assy (see 8100015-A65-C00) | 1 |

| 17 | 8107080-A65-C00 | Evaporator temp sensor (see 8100015-A65-C00) | 1 |

The specifications for the FAW Automatic Air Conditioning With Dual-Zone Climate Control are defined by its function as a multi-part, sensor-driven, automatic HVAC system.

| Vehicle Application | FAW Jiefang CA4251P66K24T1A3E5 6×4 Tractor |

| Component Group | FAW Automatic Air Conditioning With Dual-Zone Climate Control |

| System Type | “Dual-Box” Automatic Climate Control (HVAC) |

| Logic | Sensor-Driven, Automatic Temperature Blending |

| Component 1 (Cold) | ‘Evaporator assy’ (8107030-A65-C00) |

| Component 2 (Hot) | ‘Heater core assy’ (8101210-A65-C00) |

| Component 3 (Air) | ‘Blower assy’ (8101040-A65-C00) |

| Component 4 (Brain) | ‘Speed control module’ (8101080-A65-C00) |

| Component 5 (Nerves) | ‘A/C electric harness assy’ (3724090AD04) |

| Sensors | In-Cab Temp, Evaporator Temp, Freeze Temp |

| Actuators | ‘Central drive’ (8101051-A65-C00), ‘Cold/warm air door’ (8101025-A65-C00) |

FAW parts, including the Cylinder Block Assembly, are packaged with care to ensure safe delivery. Each component is secured in protective materials to prevent damage during transit. The logistics network guarantees timely shipments worldwide, supporting efficient maintenance operations. Below is an image illustrating the standard packaging for FAW truck parts, showcasing the attention to detail in handling and storage.

This packaging approach minimizes the risk of corrosion or impact damage, ensuring that parts like the FAW Cylinder Block Assembly arrive in perfect condition. Customers can rely on FAW’s logistics for consistent quality and reliability.