Welcome to this comprehensive technical guide on the FAW Air Brake Module Assembly (Assembly 542). This is the complete, chassis-mounted pneumatic control and air storage system for the FAW Jiefang CA4251P66K24T1A3E5 6×4 diesel semi-trailer tractor. This assembly is the “power pack” for the truck’s entire braking system.

The FAW Air Brake Module Assembly is a “logic” system that integrates multiple components. Its function is to safely store the high-pressure air generated by the compressor in the ‘Air storage tank assembly’ (3513055-91W) and to house the vehicle’s batteries on a single, secure, chassis-mounted bracket.

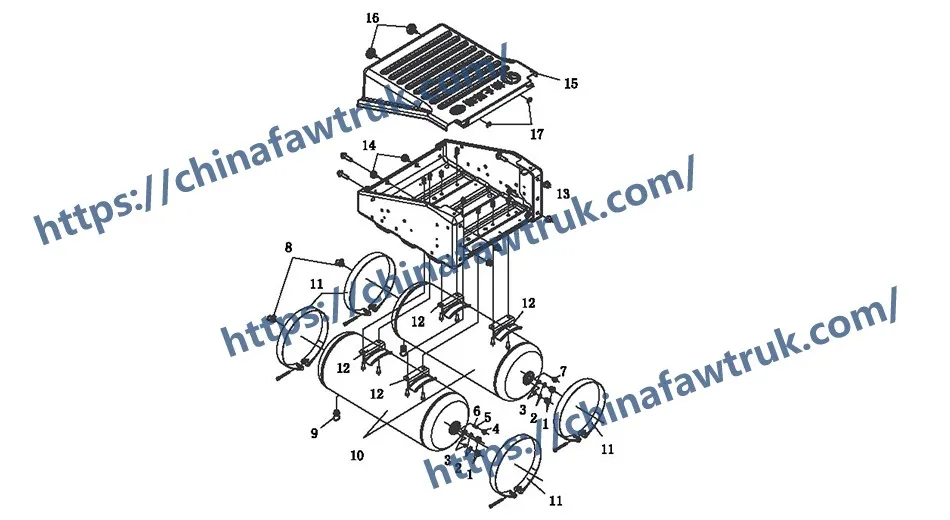

This in-depth guide is an essential resource for professional chassis technicians and fleet managers. We will deconstruct the entire FAW Air Brake Module Assembly into its 17 serviceable component types, including the air tanks, the main ‘Air storage tank & battery bracket assy’ (3513800-91W), the ‘Drain valve’, and all the critical fittings and high-tensile fasteners that make this system safe and reliable.

The heart of the FAW Air Brake Module Assembly is the ‘Air storage tank assembly’ (3513055-91W), also known as the “air reservoir” or “air tank.” The parts list calls for two of these. These are heavy-duty, steel-walled cylinders designed to safely store compressed air at pressures exceeding 120 PSI (8.3 bar).

This is the “power supply” for the entire brake system. The “logic” of a pneumatic FAW Air Brake Module Assembly is to have a large volume of pre-compressed air ready at all times. When the driver hits the brake pedal, it’s not their foot pressure doing the work; they are simply opening a valve that releases this massive, stored energy to the brake chambers.

These tanks must be in perfect condition. Over time, moisture from the air system can settle in the bottom, causing internal rust. This rust can flake off, travel down the FAW Air Brake Module Assembly, and clog the sensitive brake valves. A heavily-rusted tank can, in a worst-case scenario, rupture under pressure, leading to a catastrophic and total loss of all braking power.

The “logic” of the FAW Air Brake Module Assembly is its integrated design. The ‘Air storage tank & battery bracket assy’ (3513800-91W) is the main “skeleton” of the assembly. This is a complex, heavy-duty fabricated steel bracket that serves two purposes:

This “logic” of combining the air tanks and battery box into one module saves space on the chassis rail, a critical commodity on a modern tractor. The ‘Air storage tank bracket’ (3513081-91W) units are the individual mounts that are part of this main assembly.

The most important service “logic” on the FAW Air Brake Module Assembly is the ‘Drain valve assembly’ (3513100-1500). There are two of these, one for each tank. Air from the compressor inevitably contains some moisture. This moisture condenses and settles at the bottom of the air tanks. The “logic” of the drain valve is to provide a simple, manual way to “drain” this corrosive water from the system daily, protecting the entire FAW Air Brake Module Assembly from internal rust and freeze-up in cold weather.

The FAW Air Brake Module Assembly is a sealed, high-pressure system that relies on a complex array of “fittings” (grommets) and service ports. The parts list calls for a large quantity of these:

These are the “ports” where the high-pressure nylon air lines (from Assembly 539) connect to the air tanks. The “grommet” design is a “push-to-connect” fitting, sealed with ‘Special-shaped sealing rings’ (3513403-1500, 3506403-1500) and held in place by ‘Circlips’ (3513407-1500, 3506407-1500). This “logic” allows for a fast, reliable, and field-serviceable connection. A failure of one of these O-rings or ‘Gasket rings’ (3513839-91W) will result in a “slow leak,” causing the air compressor to cycle constantly and potentially draining the FAW Air Brake Module Assembly overnight.

The ‘Quick-connect test connector’ (T833) is a diagnostic “logic” port. It allows a technician to quickly connect a pressure gauge to the FAW Air Brake Module Assembly to test the system pressure without having to disconnect a main line.

The FAW Air Brake Module Assembly holds hundreds of pounds of steel (tanks and batteries) and is subjected to constant road vibration. Its fastener system is critical to its safety and function.

**Chassis Mounts:** The main ‘Air storage tank & battery bracket assy’ (3513800-91W) is secured to the truck’s frame with four ‘Hex head flange lock nuts’ (CQ32614) and four ‘Hex flange bolts’ (Q1841445T). The “flange” and “lock nut” design is a “logic” choice to prevent loosening under vibration.

**Tank Mounts:** The ‘Air storage tank brackets’ (3513081-91W) are secured with ‘Hex head bolts’ (CQ1501025), ‘Hex nuts’ (CQ34010), and ‘Spring gaskets’ (Q40310). The ‘Tank strap assembly’ (3513095-91W) is tightened with ‘Inner hex socket head cap screws’ (CQ2180870Q).

**Battery Mounts:** The ‘Battery cover plate’ (3513801-91W) is secured by ‘Locking clamps’ (3513837-91W, 3513837-2000), which are locked down with ‘Cotter pins’ (3513839-91W). This “pin” logic is a quick-release, yet positive-locking, mechanism that allows for battery service while ensuring the heavy batteries cannot escape. This entire hardware set is essential to the integrity of the FAW Air Brake Module Assembly.

The following table provides the complete, detailed breakdown of all 17 component types identified in the ‘Air Brake Module Assembly’ (542) diagram for the FAW CA4251P66K24T1A3E5 tractor.

| Mark | Part No. | Part Name | Quantity |

|---|---|---|---|

| 1 | 3513410-1500 | Grommet (M22) with sealing ring assy | 4 |

| 2 | 3513407-1500 | Circlip (Ф12) | 4 |

| 3 | 3513403-1500 | Special-shaped sealing ring (Ф15.2) | 4 |

| 4 | 3506410-1500 | Grommet (M16) with sealing ring assy | 1 |

| 5 | 3506407-1500 | Plug (Ф10) | 1 |

| 6 | 3506403-1500 | Special-shaped sealing ring (Ф9.7) | 1 |

| 7 | 3506415-1500 | Plug chamber (M16) with sealing ring assy | 1 |

| 8 | T833 | Quick-connect test connector | 1 |

| 9 | 3513100-1500 | Drain valve assembly | 2 |

| 10 | 3513055-91W | Air storage tank assembly | 2 |

| 11 | 3513095-91W | Tank strap assembly | 4 |

| CQ2180870Q | Inner hex socket head cap screw | 4 | |

| 12 | 3513081-91W | Air storage tank bracket | 4 |

| CQ1501025 | Hex head bolt | 8 | |

| CQ34010 | Hex nut | 8 | |

| Q40310 | Spring gasket | 8 | |

| 13 | 3513800-91W | Air storage tank & battery bracket assy | 1 |

| CQ32614 | Hex head flange lock nut | 4 | |

| Q1841445T | Hex flange bolt, coarse rod (Standard Type) | 4 | |

| 14 | 3513837-91W | Locking clamp | 2 |

| 15 | 3513801-91W | Battery cover plate | 1 |

| 16 | 3513837-2000 | Locking clamp | 2 |

| 17 | 3513839-91W | Cotter pin | 2 |

The specifications for the FAW Air Brake Module Assembly are defined by its function as an integrated, chassis-mounted air storage and battery housing. The FAW Air Brake Module Assembly is a critical, space-saving component.

| Vehicle Application | FAW Jiefang CA4251P66K24T1A3E5 6×4 Tractor |

| Component Group | FAW Air Brake Module Assembly |

| Main Bracket P/N | 3513800-91W |

| System Function 1 | Air Storage (Reservoir) |

| System Function 2 | Battery Box / Housing |

| Air Tanks | 2x ‘Air storage tank assembly’ (3513055-91W) |

| Air Tank Straps | 4x ‘Tank strap assembly’ (3513095-91W) |

| Battery Securement | ‘Battery cover plate’ (3513801-91W) & ‘Locking clamps’ (3513837-91W) |

| Service Logic | 2x ‘Drain valve assembly’ (3513100-1500) |

| Primary Function | To securely house the air reservoirs and batteries, protecting them and saving chassis space. |

FAW parts, including the Cylinder Block Assembly, are packaged with care to ensure safe delivery. Each component is secured in protective materials to prevent damage during transit. The logistics network guarantees timely shipments worldwide, supporting efficient maintenance operations. Below is an image illustrating the standard packaging for FAW truck parts, showcasing the attention to detail in handling and storage.

This packaging approach minimizes the risk of corrosion or impact damage, ensuring that parts like the FAW Cylinder Block Assembly arrive in perfect condition. Customers can rely on FAW’s logistics for consistent quality and reliability.