Welcome to this advanced technical guide for the Conjunto de colector de escape y colector de admisión FAW, a critical system for the FAW Jiefang CA4251P66K24T1A3E5 6×4 tractor semirremolque diésel. This assembly is responsible for the engine’s entire “respiración” proceso, from routing clean air in to expelling hot exhaust gases out.

Este Conjunto de colector de escape y colector de admisión FAW is a high-performance system designed to withstand extreme temperatures and pressures. It manages the flow of pressurized air from the turbocharger into the engine and simultaneously collects superheated exhaust gases to drive the turbo.

This guide is an essential resource for engine technicians, administradores de flotas, y especialistas en repuestos. Deconstruiremos todo Conjunto de colector de escape y colector de admisión FAW, including all gaskets, heat shields, sujetadores, and connecting pipes, breaking it down to the smallest serviceable unit to ensure accurate diagnostics and repairs.

El corazón de la “escape” lado de la Conjunto de colector de escape y colector de admisión FAW is a two-piece manifold. The parts list calls for two units of ‘Exhaust Manifold (I)’ (1008041-81D) and one unit of ‘Exhaust Manifold (II)’ (1008042-91W.). Para un motor de seis cilindros, this indicates a “dividir” manifold design. This is a common and critical engineering feature on heavy-duty diesel engines.

This design, likely splitting the manifold into two three-cylinder sections, is essential for managing thermal expansion. A cast-iron manifold can reach temperatures exceeding 700°C (1300° F). un solo, long manifold for six cylinders would expand and contract so much that it would warp, grieta, or shear its own mounting bolts.

By splitting the manifold, each section can expand and contract independently, dramatically reducing metal fatigue and stress. These sections are typically joined by a flexible joint or a slip-fit connection (using the ‘Exhaust pipe sealing ring’ 1008043-29D) before they enter the turbocharger. The material is a high-silicon, ductile cast iron, designed to withstand thousands of extreme heat cycles without failing.

El “consumo” portion of the Conjunto de colector de escape y colector de admisión FAW is represented by the ‘Intake Connecting Pipe’ (1008023-81D). This single component is the main artery for all the clean, pressurized air that enters the engine.

This pipe is located on the “lado frio” del motor. It is *not* the intake manifold itself, but the rigid pipe that connects the intercooler’s outlet to the engine’s intake plenum. It is typically made of cast aluminum or high-strength molded composite to be lightweight and to help keep the intake air charge cool.

The integrity of this pipe and its seals (often large O-rings, no listado) es critico. Any leak in this pipe, known as a “fuga de refuerzo,” will cause the turbocharger to work harder to produce the same pressure, leading to a severe loss of power, alto consumo de combustible, and black smoke from the exhaust. Ensuring this pipe is secure is a key diagnostic step for any low-power complaint related to the Conjunto de colector de escape y colector de admisión FAW.

The single most important serviceable part of the Conjunto de colector de escape y colector de admisión FAW is its sealing system. The parts list calls for six units of ‘Gasket – tubo de escape’ (1008044-81D). This corresponds to the six exhaust ports on the cylinder head, uno para cada cilindro.

These are not standard paper gaskets. They must be Multi-Layer Steel (MLS) juntas, composed of multiple embossed layers of stainless steel. These layers are designed to act like springs, compressing slightly when tightened. This spring-like action allows them to maintain a positive seal even as the cast-iron manifold and aluminum or iron head expand and contract at different rates.

A failure of one of these gaskets is a common issue on high-mileage engines. The primary symptom is a loud “tictac” o “puffing” sonido, especially when the engine is cold (before the metal expands). This leak is not just noisy; it is dangerous. It can vent hot, toxic exhaust fumes into the engine bay, and by allowing fresh air to be pulled *into* the manifold, it can disrupt the air-fuel ratio and cause the turbocharger to spin at an incorrect speed.

The list also specifies four ‘Exhaust pipe sealing ring’ (1008043-29D). These are not for the head-to-manifold connection. Estos son de alta temperatura “doughnut” juntas, often made of graphite composite or wire mesh. They are used to seal the slip-joints between the two manifold halves and at the final connection flange that leads to the turbocharger. They are designed to allow for slight movement and misalignment while still preventing any leaks of the high-pressure, pre-turbo exhaust gas. Replacing all six gaskets and all four rings is mandatory when servicing the Conjunto de colector de escape y colector de admisión FAW.

Asegurar el Conjunto de colector de escape y colector de admisión FAW requires a complex assortment of specialized, high-temperature fasteners. The list includes ‘Exhaust pipe long fastening bolt’ (1008051-2000), ‘Exhaust pipe fastening bolt’ (1008049-53D), and an ‘Exhaust pipe stud’ (1008049-2000) with its ‘Hex head flange lock nut’ (CQ32610).

This mix of studs and bolts is intentional. Studs are often preferred for high-heat applications because they are threaded into the “frío” cylinder head only once. This prevents wear and tear on the delicate threads in the head. The manifold then slides onto the studs, and a nut is used to apply clamping force. This is a more reliable and serviceable design.

críticamente, the list also includes two types of sleeves: ‘Exhaust pipe bolt sleeve’ (1008048-2000) and ‘Exhaust manifold long bolt sleeve’ (1008048-29D). These are not optional. These sleeves act as precision spacers, ensuring the bolt or stud can apply the correct clamping force. They also act as a heat shield for the bolt, preventing the bolt itself from getting as hot as the manifold. This is vital for preventing the bolts from stretching, loosening, or snapping, which is a common failure point in improperly serviced exhaust systems. These sleeves are a key part of the Ford Conjunto de colector de escape y colector de admisión FAW‘s robust design.

The final two components are for heat management and structural support. The ‘Exhaust pipe cover’ (1008061-81D) is a stamped metal heat shield. Its sole function is to sit on top of the manifold, creating a barrier of air. This barrier prevents the manifold’s intense radiant heat from cooking nearby components like wiring harnesses, fuel lines, or the plastic cylinder head cover. A missing heat shield will invariably lead to other, seemingly unrelated failures.

The ‘Support assembly – tubo de conexión’ (1203070-2000) is a structural brace. The heavy turbocharger and exhaust piping cannot be left to hang solely off the manifold; the vibration and weight would crack the manifold in short order. This support bracket bolts to a rigid point on the engine block and to the connecting pipe or turbo, providing the essential support needed to handle the vibration and shock loads of a heavy-duty truck. This brace is essential to the longevity of the entire Conjunto de colector de escape y colector de admisión FAW.

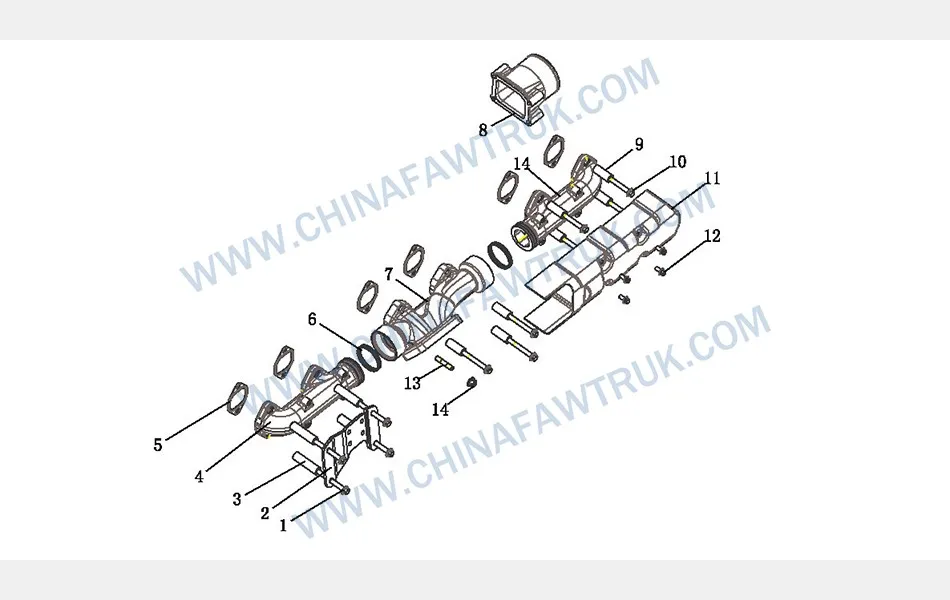

La siguiente tabla proporciona la información completa, detailed breakdown of all components identified in the ‘Exhaust Manifold and Intake Connecting Pipe Assembly’ diagrama para el tractor FAW CA4251P66K24T1A3E5.

| Marca | Número de pieza. | Nombre de la pieza | Cantidad |

|---|---|---|---|

| 1 | 1008051-2000 | Exhaust pipe long fastening bolt | 4 |

| 2 | 1203070-2000 | Support assembly – tubo de conexión | 1 |

| 3 | 1008048-2000 | Exhaust pipe bolt sleeve | 2 |

| 4 | 1008041-81D | Colector de escape (I) | 2 |

| 5 | 1008044-81D | Empaquetadora – tubo de escape | 6 |

| 6 | 1008043-29D | Exhaust pipe sealing ring | 4 |

| 7 | 1008042-91W. | Colector de escape (II) | 1 |

| 8 | 1008023-81D | Intake connecting pipe | 1 |

| 9 | 1008048-29D | Exhaust manifold long bolt sleeve | 7 |

| 10 | 1008049-53D | Exhaust pipe fastening bolt | 7 |

| 11 | 1008061-81D | Cubierta del tubo de escape | 1 |

| 12 | Q1840816 | Perno de brida hexagonal, varilla gruesa (Tipo estándar) | 4 |

| 13 | 1008049-2000 | Exhaust pipe stud | 1 |

| 14 | CQ32610 | Tuerca de seguridad con brida de cabeza hexagonal | 1 |

Las especificaciones para el Conjunto de colector de escape y colector de admisión FAW are defined by its dual role in handling both pressurized, cold intake air and superheated, pre-turbo exhaust gas.

| Solicitud de vehículo | FAW Jiefang CA4251P66K24T1A3E5 6×4 Tractor |

| Grupo de componentes | Conjunto de colector de escape y colector de admisión FAW |

| Exhaust Manifold Type | Two-Piece Split Manifold (1008041-81D, 1008042-91W.) |

| Material (Escape) | High-Silicon Cast Iron |

| Intake Pipe Type | Tubería de conexión de admisión (1008023-81D) |

| Exhaust Head Gaskets | 6x Multi-Layer Steel (MLS) Juntas (1008044-81D) |

| Exhaust Joint Seals | 4x Sealing Rings (1008043-29D) |

| Característica clave | Bolt and Stud Sleeves (1008048-xxxx) for thermal management |

| Sistema de soporte | 1x Support Assembly (1203070-2000) |

| Heat Management | 1x Exhaust Pipe Cover (1008061-81D) | Dos

piezas FAW, incluido el conjunto del bloque de cilindros, Se empaquetan con cuidado para garantizar una entrega segura.. Cada componente está asegurado con materiales protectores para evitar daños durante el transporte.. La red logística garantiza envíos puntuales en todo el mundo., apoyando operaciones de mantenimiento eficientes. A continuación se muestra una imagen que ilustra el embalaje estándar de las piezas de camiones FAW., mostrando la atención al detalle en el manejo y almacenamiento.

Este enfoque de embalaje minimiza el riesgo de corrosión o daños por impacto., asegurando que piezas como el conjunto de bloque de cilindros FAW lleguen en perfectas condiciones. Los clientes pueden confiar en la logística de FAW para obtener calidad y confiabilidad constantes.