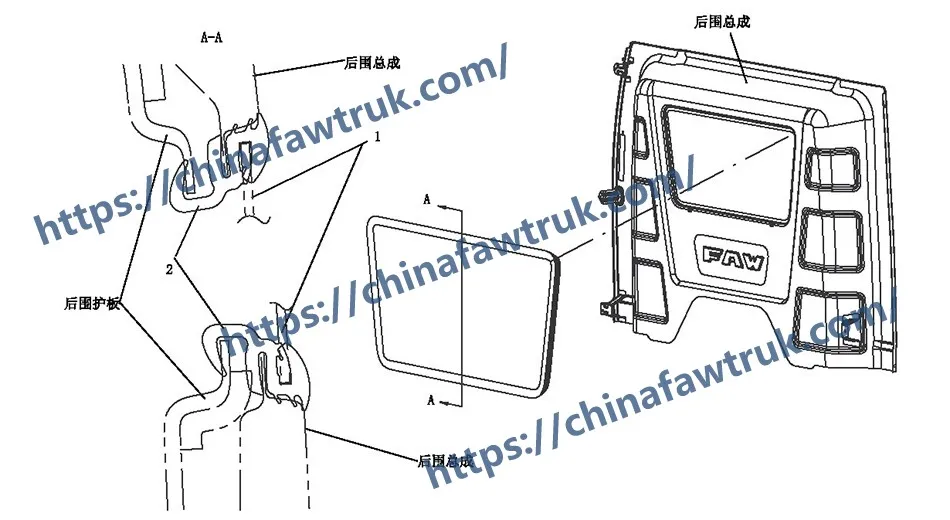

Welcome to this in-depth technical guide to the FAW Rear Window Glass assembly. This is the complete, two-component “gasket-set” window system for the rear bulkhead of the FAW Jiefang CA4251P66K24T1A3E5 6×4 diesel semi-trailer tractor. This assembly is a critical component of the cab’s “safety cell,” providing the driver with essential rearward visibility while simultaneously creating an acoustic, thermal, and weatherproof seal.

The “logic” of the FAW Rear Window Glass system is one of “floating” security. Unlike the bonded front windscreen, this assembly uses a heavy-duty, one-piece ‘Sealing strip’ (5603038-A86-C00) that both holds the ‘Rear window glass’ (5603026-A86) in place and seals it against the cab’s metal frame. This “logic” provides excellent durability against chassis flex and makes field replacement simpler.

This expert analysis is an essential resource for cab technicians, collision repair specialists, and parts managers. We will deconstruct the entire FAW Rear Window Glass assembly by analyzing its two critical Minimum Serviceable Units (MSUs). We will explore the “Tempered Safety Logic” of the glass itself and the “Triple-Seal Logic” of its all-important EPDM rubber weatherstrip.

The ‘Rear window glass’ (5603026-A86) is the primary component of the FAW Rear Window Glass system. This MSU is not just a simple pane of glass; it is a high-tech “Tempered Safety Glass” component, and its “logic” is entirely different from the *laminated* glass used in the front windscreen.

1. The “Tempering” Logic (Strength & Safety):

“Tempering” is an industrial process where the cut glass is heated to over 600°C and then “quenched” (rapidly cooled) with high-pressure air. This “logic” of thermal shock causes the outer surfaces of the glass to cool faster than the center, creating a state of high compression on the surface, balanced by high tension in the core.

This internal stress makes the FAW Rear Window Glass 4 to 5 times stronger than standard glass. This “strength logic” is essential for a truck, allowing the glass to easily withstand severe cab vibrations, thermal shock (like a hot sleeper on a cold night), and minor impacts from debris.

The “safety logic” is even more important. If the glass *does* break, the internal tension is released, and the *entire* pane instantly shatters into thousands of small, cube-like, relatively harmless “pebbles.” This is a “dicing” fracture. This “logic” is a deliberate choice for rear and side windows, as it prevents the large, razor-sharp “daggers” that are created when normal or laminated glass shatters, which could be fatal to a driver in a rollover or impact.

2. The “Visibility” Logic (Operation):

The FAW Rear Window Glass is an essential tool for the driver. Its “logic” is to provide a clear, distortion-free view of the trailer’s “kingpin” and the “fifth wheel.” This visibility is critical for safely and efficiently hooking up to a trailer, a task a driver may do multiple times per day.

It also provides a vital “blind spot” check, allowing the driver to glance back and ensure the trailer is tracking correctly, or to get a visual on the cab’s “headache rack” and the load. For this reason, the MSU must be OEM-quality optical-grade glass.

3. The “Frit” Logic (UV Protection):

Like the front windscreen, the FAW Rear Window Glass features a “frit” – the baked-on, black ceramic border. This frit is not decorative; it is a critical “logic” element.

Its primary function is to act as a UV light shield. The EPDM rubber ‘Sealing strip’ (MSU 2) that holds it in place is vulnerable to long-term sun exposure. This black ceramic band “logic” completely blocks sunlight from hitting the “inner lip” of the gasket, preventing it from drying out, cracking, and shrinking, which would cause a leak.

The ‘Sealing strip-rear window glass’ (5603038-A86-C00) is the second half of the FAW Rear Window Glass system. This is a one-piece, molded EPDM rubber gasket, and it is the “logic” behind the entire “gasket-set” installation.

Material Logic (EPDM): This MSU is made from EPDM (Ethylene Propylene Diene Monomer) rubber. This material “logic” is chosen for its superior resistance to:

The “Triple-Seal” Logic: This single gasket provides three critical sealing functions for the FAW Rear Window Glass.

The FAW Rear Window Glass and its seal are a “matched set.” The “logic” of their design dictates their installation method, which is completely different from the bonded front windscreen.

Installation “Logic” (Rope-In): This assembly uses a classic “rope-in” method.

Failure “Logic” & Serviceability:

The glass (MSU 1) fails from impact. The seal (MSU 2) fails from age. Over 7-10 years, the EPDM rubber will slowly shrink, dry out, and harden.

This “shrinkage logic” is the #1 cause of leaks. The seal will pull apart at the corners, creating a visible “gap,” or it will lose its “compression set,” allowing water to seep between the rubber and the glass.

Service Logic: Both components are individual MSUs. However, the best practice “logic” is to *always* replace them as a set. The labor to remove and reinstall the glass is the same. Trying to re-use an old, hardened ‘Sealing strip’ is a false economy that will almost certainly result in a leak. Likewise, trying to install old, rigid, tempered glass into a new, tight rubber seal places immense stress on the glass, risking a stress fracture. The FAW Rear Window Glass assembly is designed to be replaced as a 2-part kit.

The following table provides the complete, detailed breakdown of all 2 component types identified in the FAW Rear Window Glass assembly for the FAW CA4251P66K24T1A3E5 tractor.

| Mark | Part No. | Part Name | Quantity |

|---|---|---|---|

| 1 | 5603026-A86 | Rear window glass | 1 |

| 2 | 5603038-A86-C00 | Sealing strip-rear window glass | 1 |

The specifications for the FAW Rear Window Glass assembly are defined by its function as a gasket-set, structural safety-glass component for the rear cab bulkhead.

| Vehicle Application | FAW Jiefang CA4251P66K24T1A3E5 6×4 Tractor |

| Component Group | FAW Rear Window Glass |

| System Type | Gasket-Set (non-bonded), Tempered Safety Glass |

| Installation Logic | “Rope-In” method with 1-piece sealing strip. |

| MSU 1 (Glass) | ‘Rear window glass’ (5603026-A86) |

| Glass Logic | Tempered (dicing) for safety, Frit border for UV seal protection. |

| MSU 2 (Seal) | ‘Sealing strip-rear window glass’ (5603038-A86-C00) |

| Seal Logic | “Triple-Seal” (Water, Noise, Fume) via EPDM rubber. |

| Serviceability | High. Both components are MSUs, recommended for replacement as a 2-part set. |

FAW parts, including the Cylinder Block Assembly, are packaged with care to ensure safe delivery. Each component is secured in protective materials to prevent damage during transit. The logistics network guarantees timely shipments worldwide, supporting efficient maintenance operations. Below is an image illustrating the standard packaging for FAW truck parts, showcasing the attention to detail in handling and storage.

This packaging approach minimizes the risk of corrosion or impact damage, ensuring that parts like the FAW Cylinder Block Assembly arrive in perfect condition. Customers can rely on FAW’s logistics for consistent quality and reliability.