Welcome to this critical technical guide on the FAW Front Leaf Spring Assembly (Part No. 2902010A50A). This is the complete front-end suspension system for the FAW Jiefang CA4251P66K24T1A3E5 6×4 diesel semi-trailer tractor. This assembly is responsible for supporting the entire weight of the cab, engine, and transmission, while also absorbing road shock.

The FAW Front Leaf Spring Assembly is a heavy-duty, multi-leaf pack designed for durability and load-carrying capacity. Its “logic” is to provide a strong, flexible connection between the solid front axle and the truck’s frame. It must be strong enough to prevent axle movement, yet flexible enough to provide a reasonable ride quality.

This in-depth guide is an essential resource for professional suspension technicians and fleet managers. We will deconstruct the entire FAW Front Leaf Spring Assembly into its 46 serviceable components, including the main spring pack, individual leaves, U-bolts, shock absorbers, and the critical stabilizer bar.

The heart of the FAW Front Leaf Spring Assembly is the ‘Front leaf spring assembly’ (2902010A50A), of which there are two (one for the left and one for the right side). This is the main “spring pack.” It is not a single piece of steel, but a carefully engineered stack of multiple “leaves” of high-carbon spring steel.

This multi-leaf design is the core “logic” of the FAW Front Leaf Spring Assembly. It provides a “progressive” spring rate. When the truck is unladen, only the top, longer leaves flex, providing a (relatively) softer ride. As the truck is loaded, or when it hits a large bump, the load is transferred to the shorter, thicker leaves, dramatically increasing the stiffness and preventing the suspension from “bottoming out.”

This parts list breaks the pack down into its serviceable leaves, including the ‘Front leaf spring-first leaf’ (2902011A50A), ‘Front leaf spring-second leaf’ (2902012A50A), ‘Front leaf spring-third leaf’ (2902013A50A), and the ‘Hanger-rear spring eighth leaf’ (2912139-116). These leaves are all held together by the ‘Center bolt-front leaf spring’ (2902161-40A) and are kept in alignment by ‘Clips’ (2902131-50A).

The FAW Front Leaf Spring Assembly must be connected to the truck in two ways: it must be “hung” from the frame, and it must be “clamped” to the axle.

**1. Clamping (U-Bolts):** The ‘U-bolt-front leaf spring’ (2902411-56B and 2902411-92V) units are the primary fasteners. These two large, U-shaped bolts loop *over* the axle and *through* a ‘Cover-front leaf spring’ (2902406-50A). They are secured from below by the ‘Nut-fasten U-bolt’ (2902413-76A) and ‘Hex nuts’ (CQ34114, CQ35010). This “U-bolt” assembly is what rigidly clamps the middle of the FAW Front Leaf Spring Assembly to the axle, forcing the axle to move with the spring.

**2. Hanging (Shackles):** The “eyes” (ends) of the spring pack are attached to the chassis frame. The front eye bolts into a fixed “hanger” (see assembly 499). The rear eye attaches to a “shackle” (a swinging link, not fully detailed here). This “shackle” logic is what allows the FAW Front Leaf Spring Assembly to get longer and shorter as it flexes.

A spring, by itself, will “bounce” uncontrollably after hitting a bump. The “damping” logic for the FAW Front Leaf Spring Assembly is provided by the ‘Lower left support bracket assy-front shock absorber’ (2905425-2000) and the ‘Lower right support bracket assy-front shock absorber’ (2905430-2000).

These are the heavy-duty brackets that mount the *bottom* of the shock absorbers to the front axle. The shock absorber (a hydraulic piston) works against the spring: as the spring compresses and rebounds, the shock absorber provides resistance, “damping” the oscillation and forcing the tire to stay in contact with the road.

Without these brackets, the shock absorbers cannot be mounted, and the truck would be dangerously unstable, “bouncing” after every bump. A crack in one of these brackets is a critical safety failure. This sub-assembly is a key part of the FAW Front Leaf Spring Assembly‘s function.

The final “logic” of the FAW Front Leaf Spring Assembly is lateral stability, provided by the ‘Bracket-front lateral stabilizer’ (2906444-50A). These two brackets are used to mount the truck’s “stabilizer bar” (also known as an “anti-roll bar”) to the chassis.

The stabilizer bar is a long, torsion-bar spring that connects the *left* side of the axle to the *right* side of the chassis. When the truck enters a corner, “body roll” causes the outside suspension to compress and the inside suspension to extend.

The stabilizer bar’s “logic” is to resist this twisting motion. It transfers the force from the compressed (outside) spring to the extended (inside) spring, forcing the inside wheel down and “lifting” the outside of the cab. This action keeps the truck much flatter during cornering, which is a critical safety and handling feature. These brackets are the foundation for this system, making them a key part of the FAW Front Leaf Spring Assembly.

The FAW Front Leaf Spring Assembly is a high-friction, high-impact system. It relies on several “sacrificial” wear items to protect the main components.

**’Damping pad-front leaf spring’ (2902137A50A):** The parts list calls for eight of these. These are small, hard polymer or nylon pads that are inserted *between* the ends of the individual spring leaves. As the FAW Front Leaf Spring Assembly flexes, the leaves slide against each other. These pads prevent metal-on-metal “scuffing,” which would cause the springs to squeak and wear out prematurely.

**’Gasket-front leaf spring’ (2902211-50A):** The six gaskets are “insulators,” likely placed between the U-bolt’s ‘Cover’ (2902406-50A) and the spring pack, and between the axle seat and the spring pack, to provide a final layer of vibration damping and prevent metal-on-metal contact.

**’Bushing-rear leaf spring’ (2912121-03):** This is the bushing for the rear “eye” of the spring pack, where it connects to the shackle. This rubber bushing is designed to absorb the high-frequency vibrations from the road, preventing them from being transmitted into the FAW Front Leaf Spring Assembly and the chassis.

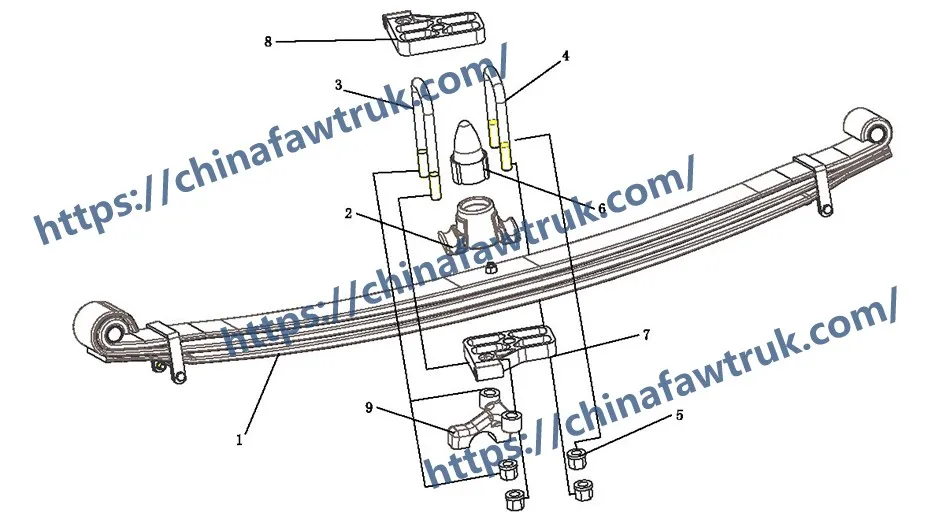

The following table provides the complete, detailed breakdown of all 46 components identified in the ‘Front Leaf Spring Assembly’ (502) diagram for the FAW CA4251P66K24T1A3E5 tractor. This FAW Front Leaf Spring Assembly is the complete front axle suspension.

| Mark | Part No. | Part Name | Quantity |

|---|---|---|---|

| 1 | 2902010A50A | Front leaf spring assembly | 2 |

| 2902011A50A | Front leaf spring-first leaf | 2 | |

| 2902012A50A | Front leaf spring-second leaf | 2 | |

| 2902013A50A | Front leaf spring-third leaf | 2 | |

| 2902105A50A | Front leaf spring first leaf & bushing assembly | 2 | |

| 2902130A50A | Front leaf spring third leaf & clip assembly | 2 | |

| 2902131-50A | Clip-front leaf spring | 4 | |

| 2902137A50A | Damping pad-front leaf spring | 8 | |

| 2902161-40A | Center bolt-front leaf spring | 2 | |

| 2902211-50A | Gasket-front leaf spring | 6 | |

| 2912121-03 | Bushing-rear leaf spring | 4 | |

| 2912139-116 | Hanger-rear spring eighth leaf (See 2912131-116) | 4 | |

| CQ1501025 | Hex head bolt | 8 | |

| CQ34114 | Hex nut | 2 | |

| CQ35010 | Hex thin nut | 8 | |

| Q4501020 | Round head rivet | 4 | |

| 2 | 2902406-50A | Cover-front leaf spring | 2 |

| 3 | 2902411-56B | U-bolt-front leaf spring | 2 |

| 4 | 2902411-92V | U-bolt-front leaf spring | 2 |

| 5 | 2902413-76A | Nut-fasten U-bolt | 8 |

| 6 | 2902432-50A | Soft pad-front leaf spring | 2 |

| 7 | 2905425-2000 | Lower left support bracket assy-front shock absorber | 1 |

| 8 | 2905430-2000 | Lower right support bracket assy-front shock absorber (symmetric with left part) | 1 |

| 9 | 2906444-50A | Bracket-front lateral stabilizer | 2 |

The specifications for the FAW Front Leaf Spring Assembly are defined by its function as a complete, heavy-duty suspension and damping system. The entire FAW Front Leaf Spring Assembly is a safety-critical system.

| Vehicle Application | FAW Jiefang CA4251P66K24T1A3E5 6×4 Tractor |

| Component Group | FAW Front Leaf Spring Assembly |

| Main Spring Assembly | 2x (Part No. 2902010A50A) |

| Spring Type | Multi-Leaf, Progressive Rate, Semi-Elliptical |

| Axle Mounting | 4x U-Bolts (2902411-56B, 2902411-92V), 2x Covers (2902406-50A) |

| Wear Items | 8x Damping Pads (2902137A50A), 6x Gaskets (2902211-50A) |

| Damping System | Shock Absorber Brackets (Left: 2905425-2000, Right: 2905430-2000) |

| Stability System | 2x Stabilizer Bar Brackets (2906444-50A) |

| Key Fasteners | 8x U-Bolt Nuts (2902413-76A), 8x Hex Thin Nuts (CQ35010) |

| Primary Function | To support the vehicle’s front-end weight, absorb road shock, and provide lateral stability. |

FAW parts, including the Cylinder Block Assembly, are packaged with care to ensure safe delivery. Each component is secured in protective materials to prevent damage during transit. The logistics network guarantees timely shipments worldwide, supporting efficient maintenance operations. Below is an image illustrating the standard packaging for FAW truck parts, showcasing the attention to detail in handling and storage.

This packaging approach minimizes the risk of corrosion or impact damage, ensuring that parts like the FAW Cylinder Block Assembly arrive in perfect condition. Customers can rely on FAW’s logistics for consistent quality and reliability.