Welcome to this critical analysis of the FAW Quick-Connect Vehicle Data Terminal (P/N: 7925040-92W). This component is a vital, yet simple, “logic” assembly for the FAW Jiefang CA4251P66K24T1A3E5 6×4 diesel semi-trailer tractor. It functions as the primary, standardized interface for accessing the vehicle’s onboard computer network (CAN bus). This “plug-and-play” port is the gateway for all modern telematics and diagnostic tools.

The “logic” of the FAW Quick-Connect Vehicle Data Terminal is one of “open access.” Unlike a fully integrated telematics box (like the ‘Vehicle Information Service Terminal’), this component provides a universal socket. This “logic” allows fleet managers to adopt a “Bring Your Own Device” (BYOD) strategy, plugging in their preferred third-party telematics or fleet management hardware (e.g., Geotab, Samsara, Verizon Connect) without any complex wire splicing.

This in-depth guide is essential for fleet managers, technicians, and parts specialists. The assembly is extremely simple, consisting of only one primary Minimum Serviceable Unit (MSU). We will deconstruct the powerful “logic” of this single terminal, explaining what data it provides, how it functions for both telematics and diagnostics, and analyzing its physical construction as the sole MSU.

The FAW Quick-Connect Vehicle Data Terminal (7925040-92W) is the answer to a major problem in the fleet industry: telematics interoperability. In the past, installing a third-party telematics device was a high-risk, high-cost procedure. A technician would have to spend hours cutting, tapping, and splicing into the truck’s OEM wiring harnesses (like the CAN bus and power lines) to “listen” to the data. This process was prone to error, could void vehicle warranties, and created multiple points of potential electrical failure.

The “logic” of this assembly is to eliminate that risk entirely. The FAW Quick-Connect Vehicle Data Terminal is an OEM-installed “data tap” or “gateway.” It provides a clean, secure, and standardized socket (typically a J1939-compliant 9-pin Deutsch connector or a 16-pin OBD-II style port) that is already integrated into the vehicle’s network.

This “plug-and-play” functionality is revolutionary for fleet management. It allows a company that operates a “mixed fleet” (e.g., FAW, Volvo, Freightliner) to use a *single* telematics provider across all their trucks. The installation process is transformed from a 3-hour wiring job into a 3-minute “plug-in” task.

The “Firewall” Logic:

This component is not just a “dumb” extension cord. The FAW Quick-Connect Vehicle Data Terminal often contains its own minimal logic board that acts as a secure “firewall.” This is a critical safety feature. It allows third-party devices to “read” (listen to) the vehicle’s broadcast data (like speed, RPM, fuel, etc.) but *prevents* them from “writing” (sending) commands back onto the CAN bus.

This “read-only” gateway logic is essential. It prevents a malfunctioning or poorly designed third-party telematics device from accidentally interfering with critical vehicle functions, such as sending a stray command that could confuse the ABS, transmission, or engine ECUs. The FAW Quick-Connect Vehicle Data Terminal ensures the safety and integrity of the truck’s core operating system.

The “Dual-Purpose” Logic:

This port serves two masters. While its primary design may be for telematics, it is also the *exact same port* a technician uses for service and diagnostics. When a truck pulls into a service bay, the technician connects their diagnostic laptop (running FAW-specific software) to this very `FAW Quick-Connect Vehicle Data Terminal`.

This dual-purpose “logic” means the port must be robust and reliable. It is the single point of entry for reading fault codes (DTCs), viewing live sensor data, and performing advanced service functions like “forced” DPF regeneration or recalibrating sensors.

When a device is plugged into the FAW Quick-Connect Vehicle Data Terminal, it gains immediate access to the rich data stream broadcast on the truck’s J1939 CAN bus. This data is the “logic” behind all modern fleet management.

Key data points provided by this interface include:

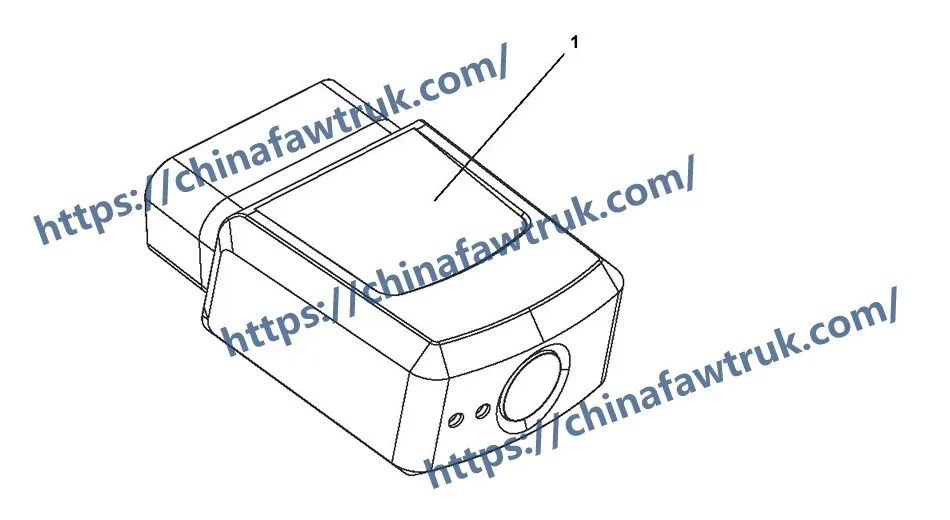

The assembly itself, the ‘Quick-connect vehicle data terminal assy’ (7925040-92W), is the single Minimum Serviceable Unit (MSU). This part is not just the port visible on the dashboard; it is a complete assembly that includes the port, a mounting bracket, and a short wiring pigtail with a connector on the back.

Construction: The port is made from high-grade, impact-resistant ABS polymer. It is designed with a specific “keying” (the shape of the port) to ensure that only the correct J1939/OBD-II connector can be inserted, and only in the correct orientation. The pins inside are high-quality, often gold-plated, to ensure a perfect, corrosion-free electrical connection over tens of thousands of insertion/removal cycles.

Failure Modes & Serviceability:

As the primary MSU of the FAW Quick-Connect Vehicle Data Terminal, failures are almost always physical.

Service is simple. A technician will unbolt the damaged FAW Quick-Connect Vehicle Data Terminal from under the dashboard, unplug its pigtail from the main cab harness, and install the new MSU. No wiring is required.

The following table provides the complete, detailed breakdown of the single component type identified in the FAW Quick-Connect Vehicle Data Terminal diagram for the FAW CA4251P66K24T1A3E5 tractor.

| Mark | Part No. | Part Name | Quantity |

|---|---|---|---|

| 1 | 7925040-92W | Quick-connect vehicle data terminal assy | 1 |

The specifications for the FAW Quick-Connect Vehicle Data Terminal are defined by its role as a universal, “plug-and-play” access port for the vehicle’s internal data network.

| Vehicle Application | FAW Jiefang CA4251P66K24T1A3E5 6×4 Tractor |

| Component Group | FAW Quick-Connect Vehicle Data Terminal |

| Main Assembly P/N | 7925040-92W |

| System Type | Telematics Gateway / Diagnostic Port (OBD/J1939) |

| Interface “Logic” | “Plug-and-Play” for 3rd-Party Telematics (BYOD) |

| Data Protocol | J1939 (CAN Bus) |

| Key Functions | Fleet Management Data, Service Diagnostics, DTC Reading |

| Security Logic | Read-Only Data “Firewall” (Typical) |

| Physical Connector | J1939 9-Pin or 16-Pin OBD-II style |

| Minimum Serviceable Unit | ‘Quick-connect vehicle data terminal assy’ (7925040-92W) |

FAW parts, including the Cylinder Block Assembly, are packaged with care to ensure safe delivery. Each component is secured in protective materials to prevent damage during transit. The logistics network guarantees timely shipments worldwide, supporting efficient maintenance operations. Below is an image illustrating the standard packaging for FAW truck parts, showcasing the attention to detail in handling and storage.

This packaging approach minimizes the risk of corrosion or impact damage, ensuring that parts like the FAW Cylinder Block Assembly arrive in perfect condition. Customers can rely on FAW’s logistics for consistent quality and reliability.