Welcome to this critical component analysis of the FAW Rear Cladding Panel Assembly (Assembly 673). This is the complete, single-piece “Noise, Vibration, and Harshness” (NVH) solution for the rear bulkhead of the FAW Jiefang CA4251P66K24T1A3E5 6×4 diesel semi-trailer tractor. This component, the ‘Rear surround sound-deadening cotton’ (5602401-B27), is a critical part of the cab’s “comfort logic.”

The “logic” of the FAW Rear Cladding Panel Assembly is to create a quiet, insulated, and premium-feeling cab environment. It is not the final, visible trim panel, but rather the high-performance “underlayment” that is installed directly against the cab’s ‘Welded Cab Assembly’ (Assembly 617) metal bulkhead. This single piece of “sound-deadening cotton” has a sophisticated, multi-function “logic” that is essential for driver comfort.

This in-depth guide is a crucial resource for cab technicians, body shop specialists, and parts managers. We will deconstruct this entire single-part FAW Rear Cladding Panel Assembly. We will analyze its “Acoustic Absorption Logic” (how it kills noise), its “Thermal Barrier Logic” (how it saves fuel), its “Anti-Rattle Logic” (how it stops squeaks), and its critical failure modes (water saturation).

The primary “logic” of the FAW Rear Cladding Panel Assembly is “sound deadening” (消音). A cab-over-engine design places the driver in a large, metal “box” (the cab) that sits directly over the engine and transmission, and is connected to a vibrating chassis. This metal box is, essentially, a giant drum.

The ‘Rear surround sound-deadening cotton’ (5602401-B27) is the MSU that “deadens” this drum. Its “logic” is two-fold: sound absorption and sound damping.

1. Absorption Logic (High-Frequency Noise):

This component is not a “sound blocker” like a dense rubber mat. It is a “sound absorber.” It is manufactured from a thick, fibrous, open-cell material (like synthetic shoddy, jute, or specialized acoustic fibers).

The “logic” is that high-frequency sound waves (like “wind whistle” from the ‘Upper Grille’ (637) or “tire hiss” from the road) are not solid forces. They are energy. When these waves penetrate the fibrous mat of the FAW Rear Cladding Panel Assembly, they are forced to travel through a “maze” of millions of tiny fibers.

With each “bounce” off a fiber, the sound wave loses energy, which is converted into a tiny, harmless amount of heat (a process called “frictional loss”). This “acoustic trap” logic is extremely effective at “soaking up” the high-frequency sounds that are most annoying and fatiguing to the human ear.

2. Damping Logic (Low-Frequency Noise):

The second “logic” is to stop “resonance.” The large, flat, metal ‘Welded Cab Assembly’ (617) rear wall has a “natural frequency.” When the engine or drivetrain vibrates at that same frequency, the wall will “resonate”—it will start to vibrate and amplify that noise, like a giant drum skin.

This FAW Rear Cladding Panel Assembly acts as a “constraining layer” or “damper.” By being “glued” (or clipped) to the metal, its mass and soft, non-resonant properties “deaden” the panel. It changes the resonant frequency of the metal and physically prevents it from vibrating. This “damping logic” is what stops the low-frequency “drone” and “boom” that is common in large, flat-paneled vehicles.

The second “logic” of the FAW Rear Cladding Panel Assembly is heat insulation (隔热). The fibrous material is, by its very nature, a “logic” insulator. Its “insulation logic” is based on “trapped air.”

The “logic” of all insulation (from a winter coat to home fiberglass) is not the material itself, but the *air* it traps. The millions of tiny air pockets trapped within the fibers of this MSU are “still air.” Still air is a very poor conductor of heat.

Summer Logic (Heat Blocking): In the summer, the sun beats down on the cab’s large, metal rear wall, turning it into a “radiator” that “soaks” heat into the sleeper. This FAW Rear Cladding Panel Assembly acts as a thermal break, preventing this radiant and conductive heat from ever reaching the cab’s interior. This “logic” of insulation drastically reduces the load on the A/C system, which in turn saves fuel.

Winter Logic (Heat Retention): In the winter, this same “logic” works in reverse. It becomes a “thermal blanket.” It traps the driver’s hard-earned “cab heat” (from the HVAC) and prevents it from escaping through the large, cold, uninsulated metal wall. This “heat retention” logic is critical for sleeper comfort and reduces heater run-time.

The final “logic” of the FAW Rear Cladding Panel Assembly (5602401-B27) is to serve as a “buffer” or “gasket.”

NVH Damping Logic: This MSU is the component that is “sandwiched” between the *structural* metal cab wall (Assembly 617) and the *cosmetic* interior plastic trim panel (sold separately).

The “logic” of this pad is to provide a “soft” interface between these two hard surfaces. This “buffer” logic prevents the hard plastic trim from vibrating against the hard metal wall. This is the #1 cause of “dashboard squeak” or “panel buzz.” This simple pad’s anti-rattle function is a key contributor to a quiet, fatigue-free ride.

Serviceability & Failure Logic:

The ‘Rear surround sound-deadening cotton’ is a single, die-cut MSU. Its “logic” is a perfect, drop-in fit. However, it is highly susceptible to one critical failure: **water saturation**.

If the ‘Rear Window Glass’ (Assembly 635) seal fails, or the ‘Upper Grille’ (Assembly 637) seal fails, water will leak *behind* the trim and soak into this FAW Rear Cladding Panel Assembly. The fibrous material will act like a giant sponge.

Once saturated, it *cannot* be dried. It will hold this moisture against the metal cab wall, leading to catastrophic, hidden rust. It will also breed mold and mildew, ruining the air quality in the cab. The “service logic” is clear: a water-damaged pad *must* be replaced. A torn or “cut-up” pad (from a previous, lazy repair) is also useless, as it loses its acoustic and thermal “logic.”

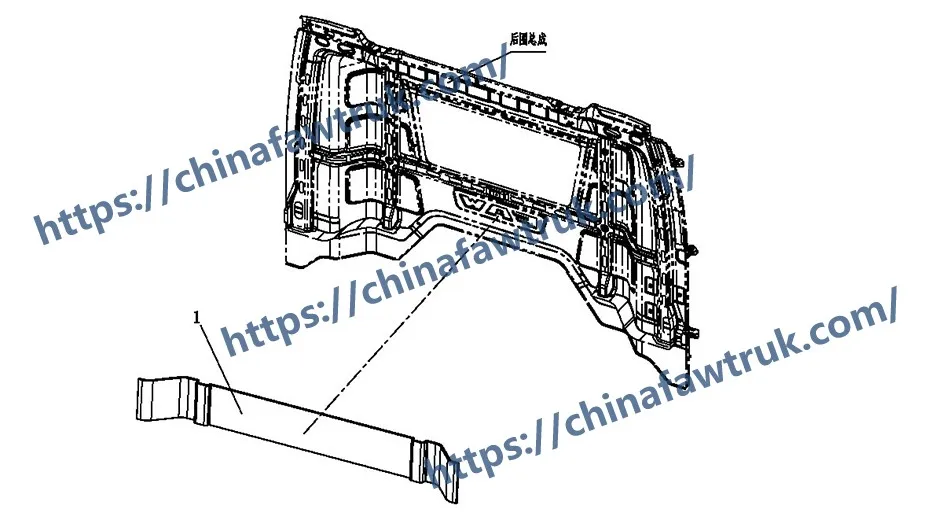

The following table provides the complete, detailed breakdown of the single component identified in the FAW Rear Cladding Panel Assembly for the FAW CA4251P66K24T1A3E5 tractor.

| Mark | Part No. | Part Name | Quantity |

|---|---|---|---|

| 1 | 5602401-B27 | Rear surround sound-deadening cotton | 1 |

The specifications for the FAW Rear Cladding Panel Assembly are defined by its function as a multi-logic NVH component for the rear cab bulkhead.

| Vehicle Application | FAW Jiefang CA4251P66K24T1A3E5 6×4 Tractor |

| Component Group | FAW Rear Cladding Panel Assembly |

| System Type | Acoustic Absorber, Thermal Insulator, and Damping Pad |

| Logic 1 (Acoustic) | High-Frequency Sound Wave Absorption (Anti-Hiss) |

| Logic 2 (Thermal) | Trapped-Air Thermal Barrier (Heat/Cold Insulation) |

| Logic 3 (NVH) | Anti-Rattle Buffer, Resonance Damping (Anti-Drone) |

| Material | Fibrous Cotton/Jute/Synthetic Mat (Open-Cell) |

| MSU 1 (Main) | ‘Rear surround sound-deadening cotton’ (5602401-B27) |

| Form Factor | Single-piece, 3D molded / Die-cut |

| Failure Mode | Water Saturation (from leaks), Tearing, Contamination |

| Serviceability | High. Single MSU, must be replaced if wet, torn, or contaminated. |

FAW parts, including the Cylinder Block Assembly, are packaged with care to ensure safe delivery. Each component is secured in protective materials to prevent damage during transit. The logistics network guarantees timely shipments worldwide, supporting efficient maintenance operations. Below is an image illustrating the standard packaging for FAW truck parts, showcasing the attention to detail in handling and storage.

This packaging approach minimizes the risk of corrosion or impact damage, ensuring that parts like the FAW Cylinder Block Assembly arrive in perfect condition. Customers can rely on FAW’s logistics for consistent quality and reliability.