Welcome to this expert technical guide on the FAW Drain Valve Logic Assembly, a critical service component for the cooling system of the FAW Jiefang CA4251P66K24T1A3E5 6×4 diesel semi-trailer tractor. This assembly is the primary interface for safely servicing the engine’s coolant.

The function of the FAW Drain Valve Logic Assembly is to provide a clean, remote-operated, and accessible drain point for the engine’s radiator. On modern, complex trucks, the radiator’s low point is often inaccessible. This “logic assembly” relocates the *control* of the drain to an easy-to-reach spot, typically via a handle and bracket.

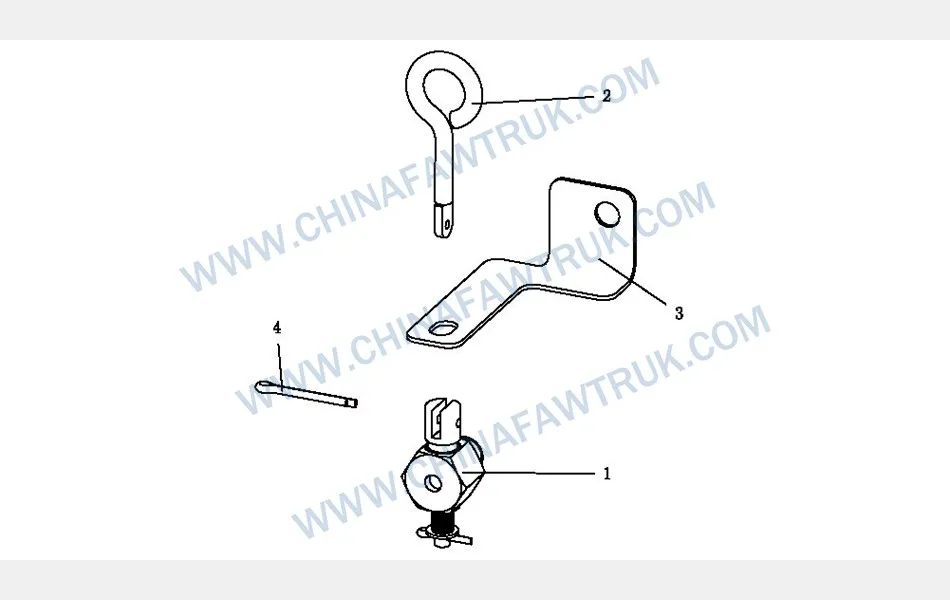

This guide is an essential resource for professional technicians, fleet maintenance managers, and parts specialists. We will deconstruct the entire FAW Drain Valve Logic Assembly (Part No. 1305010-29D) into its smallest serviceable units, including the valve itself, the remote handle, the mounting bracket, and the simple-but-critical cotter pin.

The core of the FAW Drain Valve Logic Assembly is the ‘Drain Valve Assembly’ (1305010-29D) itself. This is the “petcock” or tap that is physically threaded into the lowest point of the radiator, or an associated coolant pipe. This is the component that holds back the entire cooling system’s volume of hot, pressurized antifreeze.

This is not a simple plumbing fixture. It must be engineered from materials that will not corrode or degrade when exposed to engine coolant (a mix of glycol and anti-corrosion additives) and extreme temperatures that can range from -40°C to over 120°C. It is typically made of a high-strength brass body or a reinforced, heat-resistant polymer.

The sealing mechanism is critical. The valve uses high-temperature O-rings or a precision-lapped “gate” to create a perfect, drip-free seal, even when under 15-20 PSI of cooling system pressure. A failure of this component is a major issue. If the FAW Drain Valve Logic Assembly fails in the “closed” position (seizes), it makes servicing the coolant a difficult and messy job, requiring a technician to pull a large radiator hose. If it fails in the “open” position (leaks), it is a catastrophic failure that will drain the engine of coolant, leading to overheating and severe engine damage. The reliability of the FAW Drain Valve Logic Assembly is therefore a critical safety factor.

What truly defines this as a FAW Drain Valve Logic Assembly is the remote actuation system. On a large tractor, the radiator drain plug is often impossible to reach without removing shrouds, skid plates, or grilles. This “logic” system relocates the point of operation to an accessible, safe location.

The ‘Drain Valve Handle’ (1305013-29D) is the technician’s interface. It is an ergonomic T-handle or lever designed for easy, tool-free operation. It is typically mounted on the ‘Drain Valve Bracket’ (1305031-29D). This bracket is a rigid, stamped-steel component that bolts to a secure part of the chassis or radiator support, ensuring the handle is held firmly in place and does not bend or flex during use.

The handle is connected to the ‘Drain Valve Assembly’ (1305010-29D) via a long, rigid linkage rod (not pictured, but implied). When the technician pulls or turns the handle, this motion is transferred directly to the valve’s actuator, opening the drain. This “logic” is what makes the FAW Drain Valve Logic Assembly a key feature for serviceability. It allows a technician to drain hot coolant safely, from a distance, without having to put their arms near a hot engine or radiator.

The entire remote system is held together by the smallest component in the FAW Drain Valve Logic Assembly: the ‘Cotter Pin’ (Q5003025). This is a simple, “split pin” made of soft steel.

Its function is to act as a lynchpin. It is inserted through a pre-drilled hole in the handle (1305013-29D) and the linkage rod that connects to the valve. The two “legs” of the pin are then bent over, locking the handle to the rod and preventing it from falling off due to vibration.

This pin is a critical, single-use item. During any service that requires disconnecting the handle, this pin must be replaced with a new one. Re-using a fatigued cotter pin is a major risk; if it fails and falls out, the remote handle will become disconnected, rendering the entire FAW Drain Valve Logic Assembly inoperable. This small pin is the key to the system’s reliability.

The FAW Drain Valve Logic Assembly is a component that is rarely thought of until it is needed, at which point its function is critical. The primary purpose of the cooling system is to maintain the engine at its optimal operating temperature (approx. 85-95°C). However, this system must be periodically drained for several reasons:

Before the existence of the FAW Drain Valve Logic Assembly, the standard procedure was to place a wide pan under the radiator and pull off the main lower hose. This resulted in an uncontrolled, high-volume gush of hot, toxic coolant, spilling over the technician, the floor, and the truck’s subframe. It was messy, dangerous, and environmentally irresponsible.

The FAW Drain Valve Logic Assembly solves all these problems. The technician can first attach a small drain hose to the valve’s outlet, directing the flow cleanly into a container. By using the remote handle, they can then open the valve slowly, controlling the flow and preventing any splashing or burns. This is a massive improvement in both service efficiency and technician safety. The “logic” of the FAW Drain Valve Logic Assembly is therefore a logic of safety and cleanliness.

The following table provides the complete, detailed breakdown of all components identified in the ‘Drain Valve Logic Assembly’ diagram for the FAW CA4251P66K24T1A3E5 tractor. This FAW Drain Valve Logic Assembly is key to safe coolant service.

| Mark | Part No. | Part Name | Quantity |

|---|---|---|---|

| 1 | 1305010-29D | Drain Valve Assembly | 1 |

| 2 | 1305013-29D | Drain Valve Handle | 1 |

| 3 | 1305031-29D | Drain Valve Bracket | 1 |

| 4 | Q5003025 | Cotter Pin | 1 |

The specifications for the FAW Drain Valve Logic Assembly are defined by its function as a manual, remote-operated drain for the engine’s high-temperature cooling system. The FAW Drain Valve Logic Assembly must be serviced with care.

| Vehicle Application | FAW Jiefang CA4251P66K24T1A3E5 6×4 Tractor |

| Component Group | FAW Drain Valve Logic Assembly |

| System Type | Remote-Operated Petcock / Drain Valve |

| Main Valve Assembly | 1x (Part No. 1305010-29D) |

| Actuation Method | Manual (Remote Handle) |

| User Interface | 1x Drain Valve Handle (1305013-29D) |

| Mounting System | 1x Drain Valve Bracket (1305031-29D) |

| Linkage Fastener | 1x Cotter Pin (Q5003025) |

| Associated Fluid | Engine Coolant / Antifreeze |

| Primary Function | To provide a safe, clean, and remote-accessible drain for servicing the cooling system. |

FAW parts, including the Cylinder Block Assembly, are packaged with care to ensure safe delivery. Each component is secured in protective materials to prevent damage during transit. The logistics network guarantees timely shipments worldwide, supporting efficient maintenance operations. Below is an image illustrating the standard packaging for FAW truck parts, showcasing the attention to detail in handling and storage.

This packaging approach minimizes the risk of corrosion or impact damage, ensuring that parts like the FAW Cylinder Block Assembly arrive in perfect condition. Customers can rely on FAW’s logistics for consistent quality and reliability.