Welcome to this critical technical guide on the FAW One-Shaft Assembly (also known as the transmission input shaft). This is a core component group for the manual transmission in the FAW Jiefang CA4251P66K24T1A3E5 6×4 diesel semi-trailer tractor. This assembly is the primary torque-input for the entire gearbox.

Le FAW One-Shaft Assembly is the bridge between the engine’s clutch and the transmission’s gearset. Its splined “nose” receives 100% of the engine’s power from the clutch disc, and its “input gear” (1701121-A7G) transfers that power to the counter-shaft, setting the entire gear train in motion.

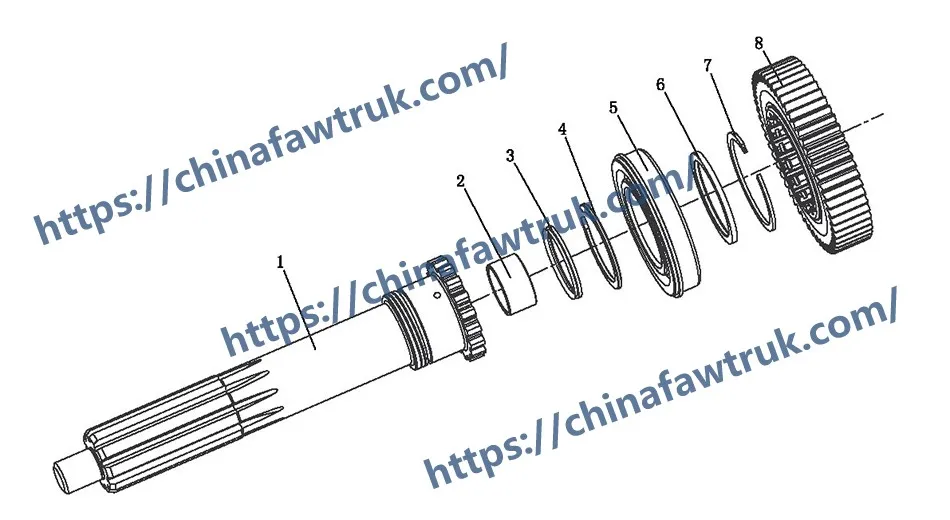

This in-depth guide is an essential resource for professional transmission technicians and parts specialists. We will deconstruct the entire FAW One-Shaft Assembly into its 8 serviceable components, including the main shaft, the ‘Input gear’, the main bearing, and the critical seals and circlips that ensure its precise alignment.

At the heart of the FAW One-Shaft Assembly are its two namesake components. The ‘First shaft – transmission’ (1701112-A7G) is the main input shaft. It is a single, robust component forged from high-carbon steel, precision-ground, and case-hardened. Its front section, ou “nose,” is precision-cut with splines. These splines slide into the hub of the clutch disc, creating the mechanical lock that receives the engine’s power.

The ‘Input gear – first shaft’ (1701121-A7G) is the main drive gear for the entire gearbox. It is fixed (splined or press-fit) onto the rear of the ‘First shaft’. This gear is in permanent, constant mesh with the main counter-shaft gear. Ce “constant mesh” design is the foundation of a heavy-duty transmission. When the engine is on and the clutch is engaged, this gear is always spinning and driving the counter-shaft. A chipped tooth on this gear, often from a severe driveline shock, is a catastrophic failure for the FAW One-Shaft Assembly.

The helical (angled) cut of the gear teeth is a critical design feature. It allows the teeth to engage gradually, which is significantly quieter than “spur” (straight-cut) engrenages. This design also allows more than one tooth to be in contact at any given time, spreading the immense torque load over a wider surface area and providing superior strength for the FAW One-Shaft Assembly.

The entire FAW One-Shaft Assembly is supported and located by the ‘Deep groove ball bearing with stop ring’ (1701105-A2V-C00). This is the main bearing for the input shaft. It is a large, heavy-duty ball bearing that is pressed onto the ‘First shaft’ (1701112-A7G). Its outer race is then secured in a precision bore in the transmission’s ‘Front Housing Assembly’ (bell housing).

A deep-groove ball bearing is used here because it is exceptionally good at handling **Radial Loads** (the sideways force from the helical gear mesh). It is also capable of handling the **Axial Loads** (le “push/pull” force) that are transmitted to the FAW One-Shaft Assembly every time the driver presses the clutch pedal.

Le “stop ring” (ou “snap ring”) on the bearing’s outer race is a critical feature. This ring fits into a groove in the transmission housing, locking the bearing (and thus the entire FAW One-Shaft Assembly) in its precise fore-and-aft position. This is a vital function for maintaining the perfect gear mesh inside the transmission. A failing bearing here will be heard as a “whine” ou “rumble” when the clutch is engaged in neutral.

This module details the two most critical “sealing” components of the FAW One-Shaft Assembly, which are responsible for connecting it to the rest of the transmission and protecting it from leaks.

**1. The ‘Bushing’ (1701111-A7G):** This is the “pilot bushing” for the transmission’s *main shaft* (ou “deuxième arbre”). The rear of the ‘First shaft’ (1701112-A7G) is hollowed out. Le “nose” ou “tip” of the transmission’s main shaft (the one with all the sliding gears) fits *inside* this hollowed-out section. This bronze bushing is pressed into this hole. It provides the front support for the entire main shaft, ensuring it is perfectly concentric with the FAW One-Shaft Assembly. A worn bushing here will cause the main shaft to “wobble,” leading to vibration, grinding shifts, and can destroy the synchronizers. It’s a tiny, but vital, part of the FAW One-Shaft Assembly.

**2. The ‘Oil seal – first shaft’ (1701135-A7G):** This is the main “input shaft seal.” It is a high-temperature, radial lip seal that is pressed into the front of the transmission’s bell housing. Its flexible, spring-loaded rubber lip rides on a polished journal of the ‘First shaft’. Its *only* job is to keep the transmission’s gear oil *inside* the transmission case.

A failure of this seal is a critical failure of the FAW One-Shaft Assembly system. It allows gear oil to leak forward into the *dry* clutch housing. This oil will immediately saturate the clutch friction disc, making it unable to grip the flywheel. The symptoms are severe clutch slip (engine revs, truck doesn’t move) and a total loss of power. This seal is a mandatory replacement item during any clutch or transmission service on the FAW One-Shaft Assembly.

Le FAW One-Shaft Assembly requires incredibly precise “end-play” (the amount of in-and-out movement). This is controlled by a “selective fit” system of circlips and a gasket.

The ‘Circlip – Premier roulement arrière d'arbre’ (1701131-A7G) and its three listed sub-parts (1701132-A7G, 1701133-A7G, 1701134-A7G) are the core of this system. This is not one part, but a *set* of circlips of minutely different thicknesses.

During a rebuild, a technician measures the “end-play” and then selects the *one* correct-thickness circlip from this set that will set the bearing “preload” to the perfect factory specification. The ‘Gasket – Premier roulement arrière d'arbre’ (1701123-A7G) is also part of this calculation, as its compressed thickness affects the final dimension.

Also listed is the ‘Circlip – marche arrière’ (1701314-A7G). This is a different part, used to locate the reverse idler gear on its own shaft (a component that meshes with the main gearset). This entire alignment system is critical to the logic of the FAW One-Shaft Assembly.

The following table provides the complete, detailed breakdown of all 8 primary components identified in the ‘One-Shaft Assembly’ (Input Shaft) diagram for the FAW CA4251P66K24T1A3E5 tractor. A rebuild of the FAW One-Shaft Assembly requires careful selection of the correct circlips.

| Mark | Partie no. | Nom de la pièce | Quantité |

|---|---|---|---|

| 1 | 1701135-A7G | Oil seal – first shaft | 1 |

| 2 | 1701131-A7G | Circlips – Premier roulement arrière d'arbre | 1 |

| 1701132-A7G | Circlips – Premier roulement arrière d'arbre (See 1701131-A7G) | 1 | |

| 1701133-A7G | Circlips – Premier roulement arrière d'arbre (See 1701131-A7G) | 1 | |

| 1701134-A7G | Circlips – Premier roulement arrière d'arbre (See 1701131-A7G) | 1 | |

| 3 | 1701105-A2V-C00 | Deep groove ball bearing with stop ring | 1 |

| 4 | 1701123-A7G | Joint – Premier roulement arrière d'arbre | 1 |

| 5 | 1701314-A7G | Circlips – marche arrière | 1 |

| 6 | 1701112-A7G | First shaft – transmission | 1 |

| 7 | 1701111-A7G | Bague | 1 |

| 8 | 1701121-A7G | Input gear – first shaft | 1 |

The specifications for the FAW One-Shaft Assembly are defined by its function as the primary torque input for the transmission. Ce FAW One-Shaft Assembly is a precision-balanced, high-strength assembly.

| Vehicle Application | FAW Jiefang CA4251P66K24T1A3E5 6×4 Tracteur |

| Component Group | FAW One-Shaft Assembly |

| Common Name | Transmission Input Shaft Assembly |

| Main Shaft P/N | 1701112-A7G |

| Main Gear P/N | 1701121-A7G (Helical-Cut) |

| Main Bearing P/N | 1701105-A2V-C00 (Ball Bearing w/ Stop Ring) |

| Main Seal P/N | 1701135-A7G (Radial Oil Seal) |

| Pilot Bushing P/N | 1701111-A7G (For Main Shaft Nose) |

| End-Play Control | Selective-fit Circlips (1701131/2/3/4-A7G) & Joint (1701123-A7G) |

| Primary Function | To transmit 100% of engine torque from the clutch disc to the transmission’s counter-shaft. |

FAW parts, including the Cylinder Block Assembly, are packaged with care to ensure safe delivery. Each component is secured in protective materials to prevent damage during transit. The logistics network guarantees timely shipments worldwide, supporting efficient maintenance operations. Below is an image illustrating the standard packaging for FAW truck parts, showcasing the attention to detail in handling and storage.

This packaging approach minimizes the risk of corrosion or impact damage, ensuring that parts like the FAW Cylinder Block Assembly arrive in perfect condition. Customers can rely on FAW’s logistics for consistent quality and reliability.