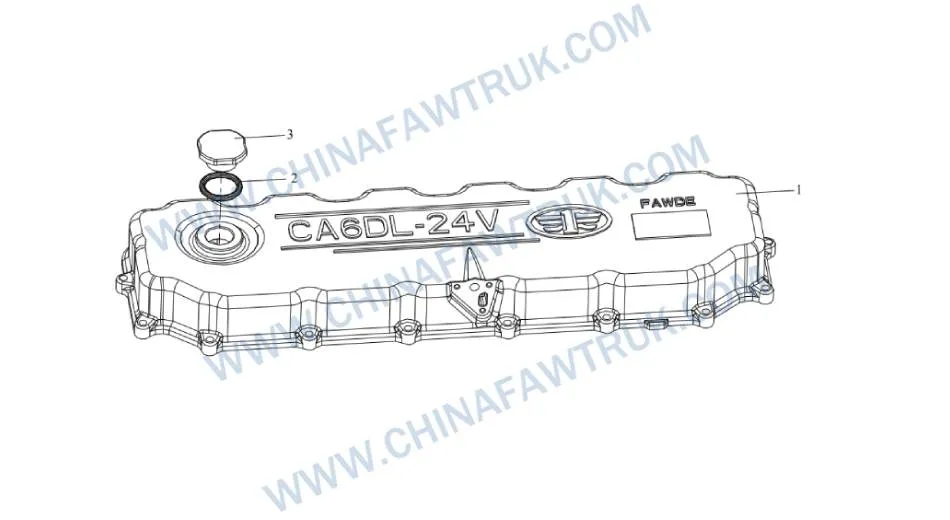

The FAW Cylinder Head Cover serves as a crucial protective component in the advanced CA3250P66K2L1T1E 6×4 dump truck engine manufactured by FAW Jiefang. This comprehensive exploded view guide provides a detailed breakdown of the cylinder head cover assembly, systematically disassembling the main housing and integrated components down to the smallest serviceable repair units. Our meticulous analysis covers the complete assembly including the oil baffle system and sealing components, enabling maintenance technicians to accurately identify, service, and replace individual parts with precision. Understanding the complete FAW Cylinder Head Cover architecture is essential for maintaining proper engine sealing, preventing oil leaks, and ensuring optimal performance in demanding heavy-duty applications where reliability is paramount for operational success.

Disassembling the FAW Cylinder Head Cover requires a systematic approach that begins with removing the main cover and progresses to internal components. The process involves carefully separating the primary housing from its integrated oil management system, ensuring each part can be individually inspected, cleaned, or replaced. Key disassembly stages include removing the hex flange bolts, accessing the oil baffle assembly, and inspecting sealing components.

The FAW Cylinder Head Cover design incorporates an integrated oil baffle system that requires specific attention during disassembly. The modular construction allows for efficient breakdown without compromising the integrity of the main cover. This approach significantly reduces repair time and costs by enabling targeted component replacement rather than complete assembly replacement.

Proper disassembly of the FAW Cylinder Head Cover ensures that critical components like sealing rings and oil baffles can be thoroughly inspected for wear or damage. Following the exploded view diagram precisely and referring to the detailed parts list guarantees accurate identification and proper handling of each component throughout the maintenance process, ensuring optimal performance after reassembly.

This comprehensive parts list for the FAW Cylinder Head Cover details every component visible in the exploded view diagram. Each part is identified by its official part number, description, and quantity required for the complete assembly. This reference enables accurate identification, ordering, and replacement of individual components during maintenance procedures.

| Reference | Part Number | Part Name | Quantity |

|---|---|---|---|

| 1 | 1003031A600-000Z | Cylinder Head Cover | 1 |

| 1 | 1003035-600-000Z | Oil Baffle Assembly | 1 |

| 1 | Q1840510 | Hex Flange Bolt | 12 |

| 2 | 1003036-29D | Sealing Ring | 1 |

| 3 | 1003037-29D | Cover Cap | 1 |

This detailed FAW Cylinder Head Cover parts list serves as an essential reference for maintenance operations. Each component is engineered to precise specifications, ensuring reliable performance under the demanding conditions typical of heavy-duty dump truck applications. When ordering replacement parts, always verify part numbers against this official list to guarantee compatibility and optimal performance of your FAW Cylinder Head Cover assembly.

The FAW Cylinder Head Cover for the CA3250P66K2L1T1E model incorporates advanced engineering features designed specifically for heavy-duty applications. The following technical parameters provide essential information for proper installation, maintenance, and compatibility verification. These specifications ensure the FAW Cylinder Head Cover meets the rigorous demands of construction and mining operations where reliability is paramount.

| Parameter | Specification |

|---|---|

| Vehicle Model | CA3250P66K2L1T1E |

| Cover Material | High-Strength Aluminum Alloy |

| Baffle Material | Stainless Steel |

| Sealing Ring Material | High-Temperature Rubber Compound |

| Bolt Type | Hex Flange Bolts |

| Number of Bolts | 12 |

| Bolt Torque Specification | 25-30 Nm |

| Weight | Approximately 8.5 kg |

| Oil Baffle Function | Prevents Oil Splashing |

| Temperature Resistance | -40°C to 180°C |

| Cover Finish | Powder Coated Black |

These technical specifications demonstrate the robust construction and engineering excellence of the FAW Cylinder Head Cover. Designed to withstand extreme operating conditions and high engine temperatures, the FAW Cylinder Head Cover ensures reliable performance throughout its service life. Regular maintenance according to these parameters will maximize durability and prevent oil leaks in your FAW truck operations.

Proper maintenance of the FAW Cylinder Head Cover is essential for ensuring optimal engine performance and preventing oil leaks in your CA3250P66K2L1T1E dump truck. Begin with regular visual inspections checking for cracks, warpage, or surface damage, particularly around sealing surfaces and bolt holes. Use the exploded view diagram as a reference during disassembly to ensure proper component identification and handling.

When servicing the FAW Cylinder Head Cover, pay special attention to the sealing ring and oil baffle assembly, which require careful installation to ensure proper oil management and prevent leaks. The hex flange bolts must be torqued to manufacturer specifications using the correct sequence to maintain even pressure distribution across the sealing surface. Always clean the mating surfaces thoroughly before reinstalling the FAW Cylinder Head Cover to ensure optimal sealing performance.

Regular inspection and replacement of the sealing ring is crucial for maintaining the integrity of the FAW Cylinder Head Cover assembly. The oil baffle should be checked for proper positioning and cleaned of any sludge buildup during maintenance intervals. Always use genuine FAW replacement parts and follow manufacturer torque specifications during reassembly to maintain the structural integrity and performance of your FAW Cylinder Head Cover system.

The FAW Cylinder Head Cover offers numerous advantages that contribute to the overall reliability and efficiency of FAW trucks. Its robust construction using high-strength aluminum alloy provides excellent durability while maintaining relatively light weight. The integrated oil baffle system effectively prevents oil splashing and ensures proper lubrication management within the valve train area.

The precision-engineered sealing system of the FAW Cylinder Head Cover ensures reliable performance under varying temperature conditions and engine vibrations. The high-temperature resistant sealing ring maintains its elasticity and sealing properties throughout the operational temperature range, preventing oil leaks and contamination of engine components. This careful engineering translates to reduced maintenance costs and extended service intervals.

The thoughtful design of the FAW Cylinder Head Cover facilitates easy access for valve adjustments and inspections while providing comprehensive protection for internal engine components. The powder-coated finish provides excellent corrosion resistance and maintains appearance over the long term. These features make the FAW Cylinder Head Cover an excellent choice for fleet operators seeking reliability, ease of maintenance, and cost-effective operation in demanding heavy-duty applications.