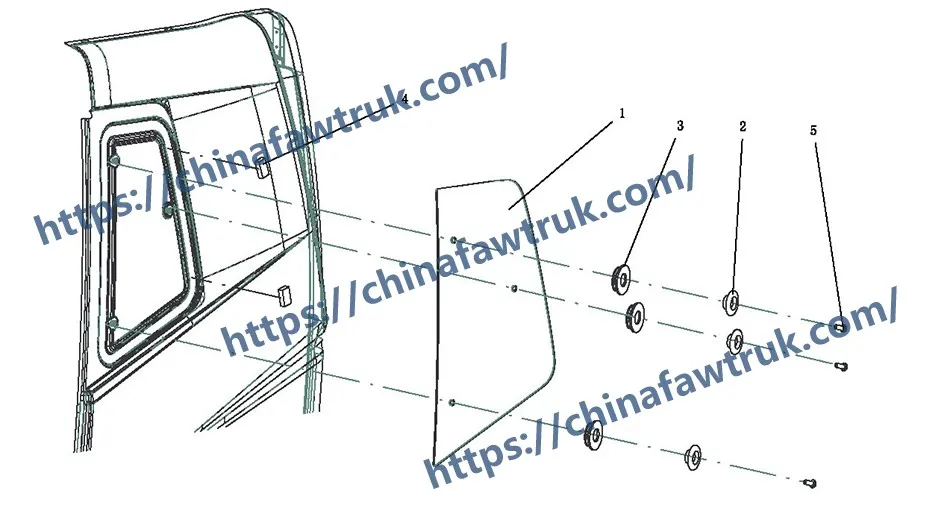

Bienvenidos a este análisis técnico en profundidad del Ventana lateral FAW asamblea. este es el completo, 5-tipo de componente, fixed-glass assembly for the rear quarter or sleeper area of the FAW Jiefang CA4251P66K24T1A3E5 6×4 tractor semirremolque diésel. Esto no es un “roll-down” ventana; es un critico “lógica” assembly designed as a fixed, sealed part of the cab’s structural integrity and safety cell.

El “lógica” del Ventana lateral FAW system is threefold. Primero, it provides critical visibility for the driver’s “punto ciego” (checking for vehicles when turning or changing lanes). Segundo, it functions as a security barrier. Tercero, y lo más importante, actúa como un “triple sello” sistema (using gaskets and limiters) to protect the cab from water leaks, ruido del viento, and dust ingress, which is vital for driver comfort and cab longevity.

This expert guide is essential for collision repair specialists, cab technicians, y gerentes de repuestos. Deconstruiremos todo Ventana lateral FAW montaje en su 5 unidad mínima útil distinta (Universidad Estatal de Michigan) tipos. Analizaremos el “Lógica de seguridad templada” of the glass itself, el “Dual Gasket Logic” of the sealing system, y el “Lógica de ajuste de precisión” of the installation hardware.

This section covers the primary MSUs of the Ventana lateral FAW: the ‘Left side window glass’ (5403041AA01) and the ‘Right side window glass’ (5403042AA01). Estos son los “ojos” de la asamblea, but their “lógica” is far more complex than just visibility.

Unlike the ‘Front Windscreen’ (Asamblea 630), which is *laminated*, this side glass is **tempered safety glass**. This is a deliberate, crítico “lógica” elección.

1. El “templado” Lógica (Fortaleza & Seguridad):

“templado” Es un proceso industrial en el que el vidrio cortado se calienta a más de 600°C y luego “apagado” (enfriado rápidamente) con aire a alta presión. Este “lógica” of rapid cooling causes the outer surfaces of the glass to cool faster than the center.

This creates a state of “internal tension,” where the surfaces are in high compression and the core is in tension. This makes the final Ventana lateral FAW 4 a 5 veces más fuerte que el vidrio estándar, allowing it to withstand severe road vibration, high-speed impacts from small debris, and thermal shock (P.EJ., hot water on a frozen window).

El “lógica de seguridad” es aún más importante. If a force is strong enough to break the glass, la tensión interna se libera, y el panel *completo* se rompe instantáneamente en miles de pequeños, en forma de cubo, relativamente inofensivo “guijarros.” Este es el “lógica” of *dicing*, which prevents the large, afilado como una navaja “dagas” of glass that are formed when standard or laminated glass breaks. This is essential for driver safety in a side impact or rollover.

2. El “Frito” Lógica (Vinculación & UV Shield):

The black border (solid and dotted) seen on every Ventana lateral FAW is called a “frit.” This is a baked-on ceramic paint. It is not just decorative; it has a critical engineering “lógica”:

3. El “Acústico” Lógica (Nvh):

This thick, heavy pane of tempered glass is a key component of the cab’s Noise, Vibración, y dureza (Nvh) paquete. Its sheer mass makes it an excellent “acoustic barrier,” reflecting and blocking high-frequency wind noise and tire “hiss.” Una alta calidad Ventana lateral FAW is a primary factor in a quiet, comfortable cab.

Este grupo de MSU es el “burlete” para el Ventana lateral FAW. The parts list calls for two different “juntas” con 6 pieces each, indicating a “lógica” of a primary structural seal and a secondary finishing seal.

Universidad Estatal de Michigan 3: ‘Rubber gasket-side window’ (5403062-A01) – Cantidad 6

This is the **Primary Seal**. This is the main EPDM rubber gasket. Es “lógica” is to create the 100% waterproof and airtight seal. es un “U-channel” empaquetadora. el vaso (Universidad Estatal de Michigan 1) sits in one channel, and the cab’s sheet metal “pinch weld” sits in the other.

Este componente “lógica” is compression. The ‘Limiter blocks’ (Universidad Estatal de Michigan 4) and ‘Screws’ (Universidad Estatal de Michigan 5) apply pressure, “squeezing” this gasket to create a 360-degree, positive seal. This is what stops all water, wind, y ruido.

Universidad Estatal de Michigan 2: ‘Decorative gasket-side window’ (5403066AA01) – Cantidad 6

This is the **Secondary Seal** or “finishing trim.” El “lógica” of this component is purely aesthetic and protective. It is the outer trim piece that covers the “seam” between the ‘Rubber gasket’ and the cab’s exterior paint. Proporciona una limpieza, “finished factory” look and also acts as a “lógica” blindaje, protecting the primary rubber gasket from direct UV exposure, which extends its life.

This final group of MSUs for the Ventana lateral FAW is the installation hardware. Es “lógica” is to ensure a perfect, vibration-proof fit that properly compresses the gasket without cracking the glass.

Universidad Estatal de Michigan 4: ‘Limiter block-side window’ (5403071-A02) – Cantidad 4

These four blocks are the key “lógica de instalación” componentes. A gasket-set window is “flotante,” not bonded. Its seal depends on *perfect* and *even* compression.

El “lógica” de estos “limiters” is to act as stand-offs. They are fastened to the inner cab frame. The installer presses the glass/gasket assembly into the opening *until* the glass makes contact with these blocks. Este “se detiene” the glass at the precise, factory-designed depth. This prevents the technician from over-tightening the fasteners and “pinching” the glass, which would lead to a stress crack.

Universidad Estatal de Michigan 5: 'Tornillo de cabeza plana empotrado en cruz’ (Q2560616F6) – Cantidad 6

These six screws are the “clamping logic.” They are used to fasten the ‘Limiter blocks’ (4) and likely a final interior retaining ring or the ‘Decorative gasket’ (Universidad Estatal de Michigan 2) en su lugar. This mechanical fastening “lógica” is what provides the clamping force for the entire Ventana lateral FAW asamblea, ensuring the gasket is compressed and the entire unit is held securely against the cab’s body, preventing all rattles and vibrations.

La siguiente tabla proporciona la información completa, desglose detallado de todos 5 tipos de componentes identificados en el Ventana lateral FAW Conjunto para el tractor FAW CA4251P66K24T1A3E5..

| Marca | Número de pieza. | Nombre de la pieza | Cantidad |

|---|---|---|---|

| 1 | 5403041AA01 | Left side window glass (see 5403041-A01) | 1 |

| 5403042AA01 | Right side window glass (see 5403041-A01) | 1 | |

| 2 | 5403066AA01 | Decorative gasket-side window | 6 |

| 3 | 5403062-A01 | Rubber gasket-side window | 6 |

| 4 | 5403071-A02 | Limiter block-side window | 4 |

| 5 | Q2560616F6 | Tornillo de cabeza plana empotrado en cruz | 6 |

Las especificaciones para el Ventana lateral FAW are defined by its function as a fixed, sellado, safety-glass component of the cab structure.

| Solicitud de vehículo | FAW Jiefang CA4251P66K24T1A3E5 6×4 Tractor |

| Grupo de componentes | Ventana lateral FAW |

| Tipo de sistema | Fixed, Gasket-Set Tempered Safety Glass |

| Lógica de vidrio | Templado (Dicing) para la seguridad, Frit-Bordered for Bonding/UV Shield |

| Lógica de sellado | Dual-Gasket (Primary EPDM Rubber + Secondary Decorative) |

| Lógica de instalación | ‘Limiter blocks’ (Universidad Estatal de Michigan 4) for precise compression depth. |

| Universidad Estatal de Michigan 1 (Vaso) | ‘Left/Right side window glass’ (5403041AA01 / 5403042AA01) |

| Universidad Estatal de Michigan 2 (Sellos) | ‘Decorative gasket’ (5403066AA01), ‘Rubber gasket’ (5403062-A01) |

| Universidad Estatal de Michigan 3 (Hardware) | ‘Limiter block’ (5403071-A02), ‘Cross… tornillo’ (Q2560616F6) |

piezas FAW, incluido el conjunto del bloque de cilindros, Se empaquetan con cuidado para garantizar una entrega segura.. Cada componente está asegurado con materiales protectores para evitar daños durante el transporte.. La red logística garantiza envíos puntuales en todo el mundo., apoyando operaciones de mantenimiento eficientes. A continuación se muestra una imagen que ilustra el embalaje estándar de las piezas de camiones FAW., mostrando la atención al detalle en el manejo y almacenamiento.

Este enfoque de embalaje minimiza el riesgo de corrosión o daños por impacto., asegurando que piezas como el conjunto de bloque de cilindros FAW lleguen en perfectas condiciones. Los clientes pueden confiar en la logística de FAW para obtener calidad y confiabilidad constantes.