Welcome to this critical technical guide on the FAW Sleeper Lighting Logic Assembly (Assembly 564). This is the complete, multi-function, interior illumination system for the sleeper berth of the FAW Jiefang CA4251P66K24T1A3E5 6×4 diesel semi-trailer tractor. This assembly is a critical component for driver comfort, safety, and operational-readiness.

The FAW Sleeper Lighting Logic Assembly is a “logic” system designed to provide effective, low-power illumination for the driver’s off-duty rest period. Its “logic” is to provide both bright, area-wide illumination and focused, low-level reading light, all while minimizing power draw from the truck’s batteries. This system consists of two ‘Sleeper lighting assembly’ (3714020-91W-C00) units.

This in-depth guide is an essential resource for professional technicians, fleet managers, and parts specialists. We will deconstruct the entire FAW Sleeper Lighting Logic Assembly into its 2 core component types (a total of 6 pieces). We will analyze the critical “logic” of the lamp units, their likely LED construction, their integration with the cab’s electrical system, and the specific, vibration-proof ‘Self-tapping screw’ (CQ2714216F6) fasteners used to mount them.

The heart of the FAW Sleeper Lighting Logic Assembly is the ‘Sleeper lighting assembly’ (3714020-91W-C00). The parts list calls for two of these, which are typically mounted on the left and right sides of the sleeper berth to provide complete, overlapping coverage.

This component is a sealed, integrated lamp unit. Its “logic” is to provide two modes of light, both essential for a driver’s comfort and utility:

**Construction and “Logic” of Illumination:** The FAW Sleeper Lighting Logic Assembly is almost certainly an **LED (Light Emitting Diode)** unit. This is a critical “logic” choice for several reasons:

* **Power Consumption (The Primary Logic):** This is the most important factor. A driver runs these lights for hours with the engine *off*, relying solely on the truck’s batteries (see Assembly 556). A traditional incandescent bulb draws a high amount of amperage, which can easily drain the batteries overnight, leading to a “no-start” situation and a costly service call. The FAW Sleeper Lighting Logic Assembly, by using low-draw LEDs, provides hours of light for a fraction of the power, protecting the batteries and ensuring the truck will start in the morning. * **Vibration Resistance:** The cab of a truck is a high-vibration environment. The fragile filament of an incandescent bulb would constantly break, leading to high maintenance. An LED is a solid-state, “shock-proof” device with no filament, making it virtually immune to vibration. * **Heat:** An incandescent bulb gets dangerously hot, creating a significant fire risk in a confined sleeper cab filled with bedding, curtains, and paper. The FAW Sleeper Lighting Logic Assembly, using cool-running LEDs, produces almost no heat, making it infinitely safer. * **Lifespan:** The LED light source is designed to last for tens of thousands of hours, often the entire life of the truck, making this a “fit-and-forget” maintenance component.

The second component of the FAW Sleeper Lighting Logic Assembly is the hardware that mounts it: the ‘Cross recessed pan head self-tapping screw’ (CQ2714216F6). The parts list calls for four of these, which is a pair of screws for each of the two ‘Sleeper lighting assembly’ units.

This is not a random choice; this fastener is a key part of the installation “logic” for the FAW Sleeper Lighting Logic Assembly.

**1. Self-Tapping “Logic”:** The “self-tapping” (自攻螺钉) design is a critical manufacturing and service feature. These screws are designed to be driven directly into an unthreaded hole in the truck’s “headliner” (the interior cab roof panel) or its underlying composite/metal support structure. The screw’s hardened threads cut (or “tap”) their own mating threads as they are installed. This “logic” creates an extremely tight, precise, and vibration-resistant fit without requiring a separate nut or pre-threaded boss, which would be impossible to access.

**2. Pan Head “Logic”:** The “pan head” (盘头) design is also a specific “logic” choice. This type of screw head is flat on the bottom with a wide diameter. When tightened, it distributes the clamping force over a wide area of the FAW Sleeper Lighting Logic Assembly‘s plastic mounting flange. A “countersunk” (tapered) screw would act as a wedge and instantly crack the plastic housing. This “pan head” logic prevents stress fractures and ensures the lamp is held *snug* against the headliner, preventing any annoying “buzzes” or “rattles” while the driver is trying to sleep.

A failure of these simple fasteners would cause the FAW Sleeper Lighting Logic Assembly to vibrate, eventually leading to a broken wire or the lamp detaching from the ceiling. Therefore, using the correct OEM-specified fastener is essential for a long-lasting, quiet, and reliable repair.

While not explicitly detailed in this parts list, the FAW Sleeper Lighting Logic Assembly is part of a wider “logic” network within the cab’s electrical system. The ‘Sleeper lighting assembly’ (3714020-91W-C00) does not function in isolation.

**1. Power Source:** The FAW Sleeper Lighting Logic Assembly is wired into the truck’s 24V “body” circuit, which is powered by the ‘Battery And Mounting Bracket Assembly’ (Assembly 556). It is a “constant-hot” circuit, meaning it has power even when the truck’s ignition key (the ‘FAW Start Switch’, Assembly 558) is in the “OFF” position. This is the “logic” that allows a driver to use the lights while resting in the sleeper.

**2. Control Interface:** The “logic” of control is multi-faceted. The lamp assembly itself contains an integrated “local” switch (e.g., a push-button or a rocker switch) that allows the driver to operate it from the sleeper berth.

**3. Courtesy Light Integration:** This FAW Sleeper Lighting Logic Assembly is also “logically” tied to the ‘Door Open Alarm Light Logic Assembly’ (Assembly 563). When the cab door is opened, the door’s plunger switch completes a ground circuit. This signal is sent to the Body Control Module (BCM), which then activates *all* interior “courtesy” lights, including this sleeper lamp. This “logic” provides a “welcome” feature, illuminating the entire cab interior so the driver can safely enter and see, before they even get to the switch on the FAW Sleeper Lighting Logic Assembly itself.

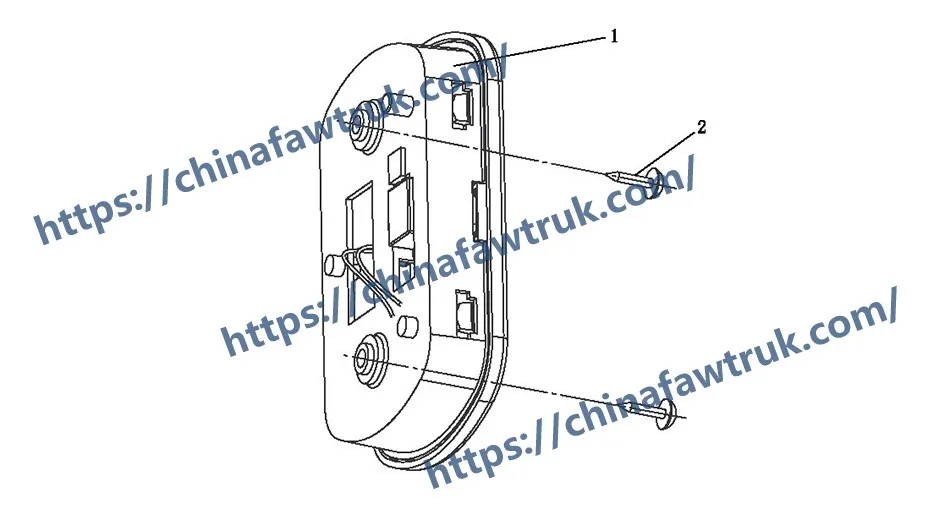

The following table provides the complete, detailed breakdown of all 4 component types identified in the ‘Sleeper Lighting Logic Assembly’ (564) diagram for the FAW CA4251P66K24T1A3E5 tractor.

| Mark | Part No. | Part Name | Quantity |

|---|---|---|---|

| 1 | 3714020-91W-C00 | Sleeper lighting assembly | 2 |

| 2 | CQ2714216F6 | Cross recessed pan head self-tapping screw | 4 |

The specifications for the FAW Sleeper Lighting Logic Assembly are defined by its function as a low-power, high-reliability, multi-mode interior illumination system. The FAW Sleeper Lighting Logic Assembly is a key component for driver comfort and safety.

| Vehicle Application | FAW Jiefang CA4251P66K24T1A3E5 6×4 Tractor |

| Component Group | FAW Sleeper Lighting Logic Assembly |

| Main Lamp P/N | 3714020-91W-C00 |

| Total Lamp Quantity | 2 |

| Common Name | Sleeper Berth Light / Interior Dome Light |

| System Voltage | 24V DC |

| Light Source (Typical) | LED (Low-power, High-vibration resistance) |

| Control Logic | Integrated switch (local) and Courtesy Light circuit (remote) |

| Mounting Hardware | 4x ‘Cross recessed pan head self-tapping screw’ (CQ2714216F6) |

| Primary Function | To provide safe, reliable, and low-power illumination for the cab’s sleeper berth. |

FAW parts, including the Cylinder Block Assembly, are packaged with care to ensure safe delivery. Each component is secured in protective materials to prevent damage during transit. The logistics network guarantees timely shipments worldwide, supporting efficient maintenance operations. Below is an image illustrating the standard packaging for FAW truck parts, showcasing the attention to detail in handling and storage.

This packaging approach minimizes the risk of corrosion or impact damage, ensuring that parts like the FAW Cylinder Block Assembly arrive in perfect condition. Customers can rely on FAW’s logistics for consistent quality and reliability.