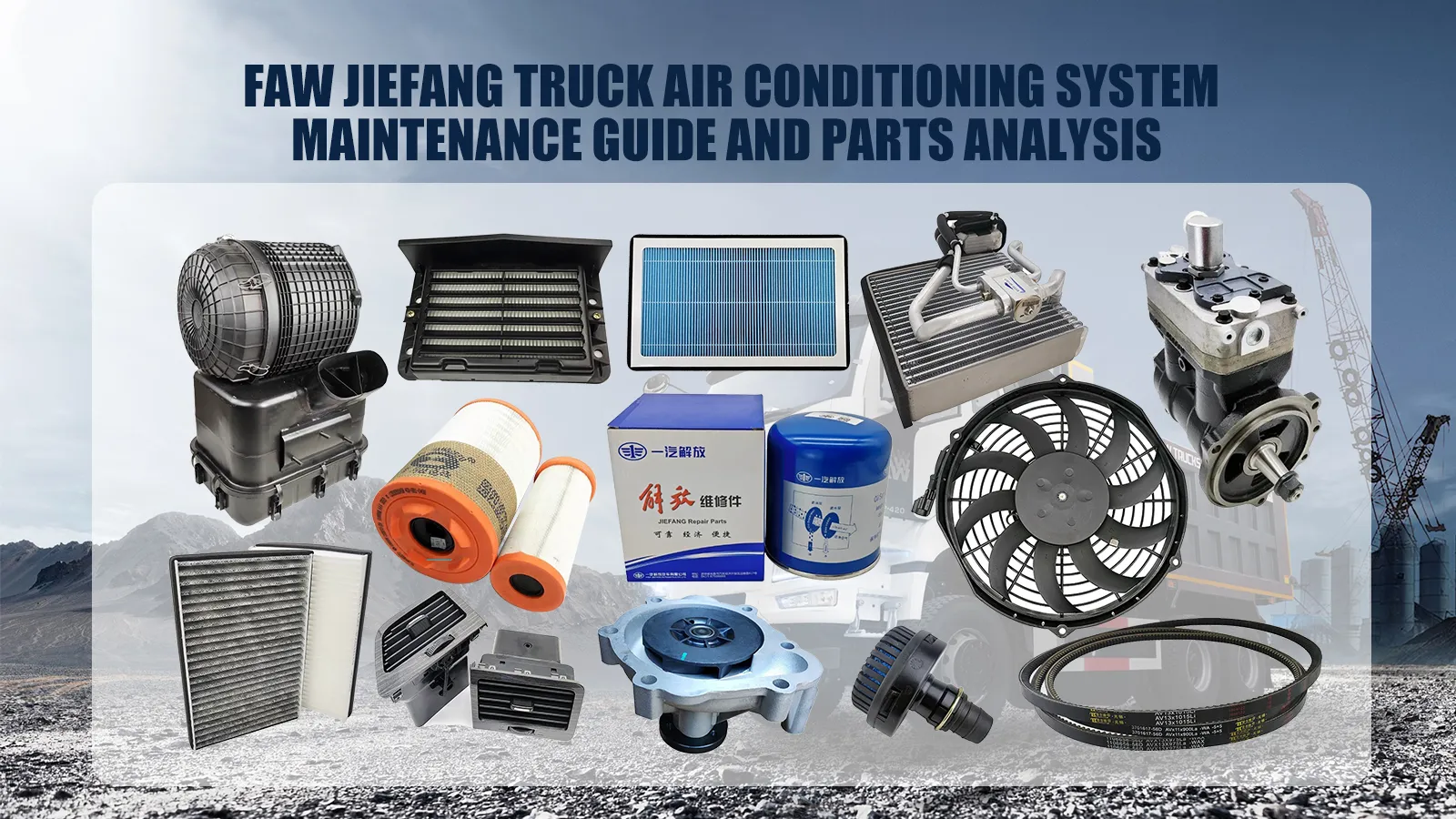

As a supplier of FAW truck parts, we are well aware of the importance of truck air conditioning system in long-distance transportation and complex working conditions. The stable operation of the air conditioning system not only affects driving comfort, but also relates to vehicle operation efficiency and cost control. The following is a comprehensive analysis and advice for customers from three aspects: maintenance items, precautions and common parts.

1.Regular replacement of air-conditioning filters

-The air conditioning filter element is the first barrier to block dust, pollen and other impurities from entering the vehicle. FAW Jiefang trucks are mostly used in dusty environments such as construction sites and mining areas, and the filter element is easy to be clogged, leading to a decrease in airflow and the breeding of odors.

-Replacement cycle: It is recommended to replace the filter every 8,000-10,000 kilometers or 3 months, and shorten it to 5,000 kilometers under adverse environment.

-Handling: The filter element is usually located in the glove compartment or under the cockpit dashboard, avoid damaging the clips when removing it. Choose a multi-layer filter (e.g. activated carbon + non-woven fabric) to combine filtration efficiency with deodorization.

2. Refrigerant inspection and replenishment

-Refrigerant (R134a) is the core medium for air-conditioning refrigeration, and its insufficiency will lead to reduced refrigeration efficiency and compressor wear.

-Detection method: through the liquid storage dryer on the visual liquid mirror observation:

-Normal state: clear without bubbles (when the compressor is running).

-Bubbles persist: refrigerant needs to be replenished; no bubbles or cloudy: possible overdose or blockage.

-Replenishment norms: special equipment must be used to avoid mixing air or impurities. It is recommended to test every 2 years. Vehicles with frequent leakage need to check the sealing of pipeline.

3. Condenser and Evaporator Cleaning

– Condenser cleaning: Located at the front of the vehicle, it is easy to adhere to insects, mud and sand, affecting the cooling efficiency.

– Cleaning method: High-pressure water gun, low-pressure flushing (water pressure ≤ 3MPa), or soft brush with neutral cleaner.

-Recommended cycle: every 15,000 kilometers or quarterly cleaning.

-Evaporator cleaning: Due to its hidden location, the dashboard should be disassembled for deep cleaning, or foam cleaner should be injected through the air duct to kill mold and remove dirt.

4. Compressor and Belt Inspection

-Belt inspection: The belt should be properly tightened, as too loose a belt will cause slippage and too tight a belt will increase bearing wear. When adjusting the belt, press the center of the belt, the sinking amplitude should be 10-15mm.

-Condition of compressor: Observe whether there are abnormal noise and vibration when running, and check whether the electromagnetic clutch suction is normal. For vehicles that have not been used for a long time, start the compressor for 10 minutes every month to lubricate the internal parts.

5. System Leak Detection and Circuit Maintenance

-Leakage detection: Focus on checking piping joints, O-rings and compressor shaft seals, and use fluorescent leak detector or electronic leak detector to locate the leakage accurately.

-Circuit Inspection: Regularly check whether the fuse and wire insulation are aging to avoid short-circuiting and causing system failure.

1. Optimization of operating habits

-Starting sequence: Turn on the air conditioner 2-3 minutes after the vehicle is started to ensure that the engine is fully lubricated.

-Pre-shutdown processing: After turning off the air conditioning cooling, keep the blower running for 3-5 minutes to blow dry the evaporator residual moisture to prevent mold growth.

-Temperature setting: 24-26°C is recommended in summer and 18-20°C in winter to avoid extreme temperature difference to increase the compressor load.

2. Environmental Adaptation Adjustment

-High dust environment: switch to internal circulation mode to reduce filter element pollution; clean condenser surface regularly.

-High temperature working condition: avoid direct sunlight when parking, use sunshade to reduce the temperature inside the car and reduce the load of air conditioner startup.

3. Regular professional overhaul

-Annual in-depth maintenance: including refrigerant pressure test, air duct sterilization, compressor lubricant replacement, etc. It is recommended to be performed by authorized service stations.

-Emergency troubleshooting: If you find a sudden drop in cooling effect, a serious odor or a strange noise, you need to stop the machine immediately for maintenance to avoid damage to other parts.

1. Air conditioning filter element

– Recommended model: FAW original multi-effect composite filter element (Model: J6F-ACF001), suitable for Jiefang J6, JH6 and other mainstream models.

-Alternative: MAN CUK2940 (strong compatibility, filtration efficiency ≥95%).

2. Refrigerant (R134a)

– Specification: purity ≥99.9%, recommended brands: Jinleng, Juhua.

– Filling quantity: Jiefang J6 standard filling quantity is 800-1000g, need to refer to the vehicle manual for precise filling.

3. Compressor drive belt

– (Original parts: Gates 6PK2280, wear-resistant and anti-stretching, suitable for Jiefang CA6DL engine).

– Testing index: no cracks on the surface, no wear on the tooth root, length tolerance ±2mm.

4. condenser/evaporator assembly

– Material selection: all-aluminum condenser (lightweight, good heat dissipation), to avoid the problem of easy corrosion of copper-aluminum composite parts of the sub-factory.

– Repair kit: including sealing gasket, fixing clips, suitable for partial replacement scenarios.

5. Liquid storage drying tank

– Function: Filter water and impurities, maintain refrigerant stability.

– Replacement cycle: every 2 years or mandatory replacement after the system is open for maintenance.

6. Expansion valve and pressure switch

– Failure performance: uneven cooling, high pressure tube frost.

– Selection points: match the system pressure range (e.g. H-type expansion valve is suitable for large-displacement trucks).

7. Pipe joints and O-rings

-Material standard: Nitrile rubber (oil resistance, high temperature resistance), original part code: J6-ACR012.

8. Cleaner & Lubricant

– Duct Cleaner: Neutral pH (7-9) to avoid corrosion of aluminum evaporator.

– Compressor lubricant: PAG46 or POE oil, refer to compressor nameplate for filling quantity.

The maintenance of FAW Jiefang truck air conditioning system maintenance guide of FAW Jiefang trucks needs to take into account the characteristics of high load and long mileage, and emphasize on preventive maintenance and parts suitability. As a supplier, we suggest customers to establish a maintenance system of “regular inspection + replacement as needed”, and prioritize the use of OEM certified parts to ensure the reliability and economy of the system. For further technical support or spare parts supply, please contact our service team and we will provide one-stop solution.

FAW is one of China’s oldest and largest automotive manufacturers, with registered capital of RMB 35.4 billion yuan and total assets of RMB 457.83 billion yuan.

CHINA FAW GROUP CO., LTD. (short for FAW), formerly China First Automobile Works, can trace its roots back to Jul 15, 1953, when its first assembly plant started to be constructed. FAW is one of China’s oldest and largest automotive manufacturers, with registered capital of RMB 35.4 billion yuan and total assets of RMB 457.83 billion yuan.

China heavy truck sales global “five in a row”, heavy truck sales global “six in a row”, tractor sales for 16 consecutive years absolute leading industry.

{FAW}

We will contact you immediately

Hello, what VIN code for Faw J6 or J7 parts do you need?

WhatsApp Us

🟢 Online | Privacy policy

WhatsApp us