Welcome to this critical technical guide on the FAW Transmission Mounting Logical Assembly. This is the complete, heavy-duty rear support system for the manual transmission, designed specifically for the FAW Jiefang CA4251P66K24T1A3E5 6×4 diesel semi-trailer tractor. This system is the structural “cradle” that supports the entire weight of the gearbox and isolates it from the chassis.

Le FAW Transmission Mounting Logical Assembly is not the transmission itself, but rather the set of “Gauche” (1706051A91W) et “Right” (1706052A91W) brackets that bolt to the rear of the gearbox. These brackets then rest on the chassis crossmember (see Assembly 323), providing a flexible, vibration-damped connection.

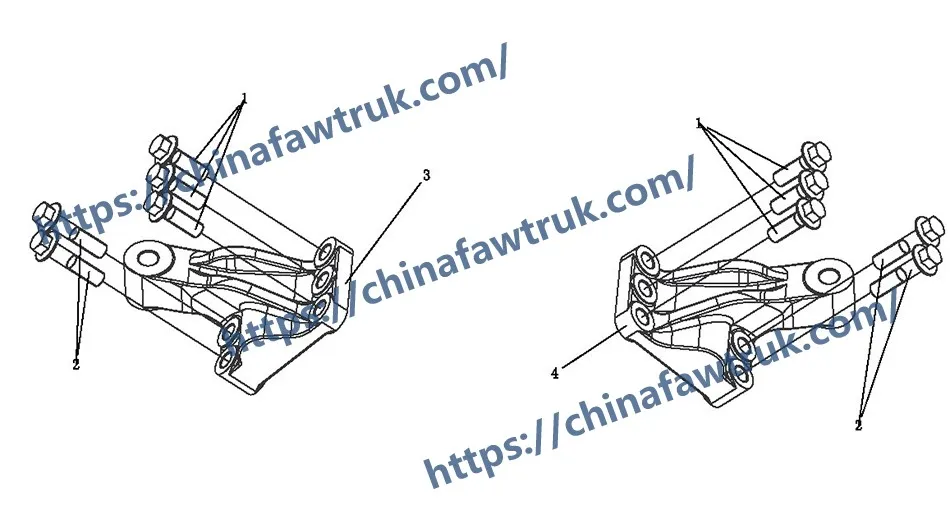

This in-depth guide is an essential resource for professional chassis technicians, fleet managers, and parts specialists. We will deconstruct the entire FAW Transmission Mounting Logical Assembly into its 4 serviceable components, explaining the function of each bracket and the critical, high-tensile flange bolts used to secure them against the immense torque and vibration of a heavy-duty powertrain.

The heart of the FAW Transmission Mounting Logical Assembly consists of a symmetrical pair of heavy-duty support brackets:

These are not simple “L” supports. They are massive, complex castings, typically made from high-strength ductile iron or fabricated steel. They are heavily ribbed and gusseted to provide maximum rigidity against “torque-twist.” Their primary function is to act as the “feet” of the transmission. They bolt directly to the sides of the transmission’s rear housing (the auxiliary “sub-box”).

Le “logic” of this FAW Transmission Mounting Logical Assembly is to provide a wide, stable platform. The flat, lower surfaces of these brackets are what rest on top of the ‘Transmission mounting flexible cushion assy’ (the large rubber mounts, detailed in Assembly 323). Ce “bracket-on-cushion” design is what isolates the powertrain from the chassis, which is the entire purpose of a modern FAW Transmission Mounting Logical Assembly.

A crack or failure in one of these brackets is a catastrophic structural failure. It would cause the entire rear of the transmission to “sag” or drop. This would immediately misalign the entire driveline, changing the driveshaft’s “U-joint angles,” which would cause severe vibration, and eventual failure of the U-joints, center support bearing, or the transmission’s output shaft bearing. The integrity of this FAW Transmission Mounting Logical Assembly is therefore critical to the entire driveline.

The final two components of the FAW Transmission Mounting Logical Assembly are the high-tensile fasteners that secure the brackets to the transmission housing. A mount is only as strong as its bolts.

The parts list calls for two different bolt sizes, totaling 10 boulons:

These are not standard hardware. Le “bride” head is an integrated washer. This is a critical design choice for mounting a steel bracket to an (often) aluminum transmission housing. The wide flange distributes the immense clamping force over a larger surface area, preventing the hard steel bolt from “digging into” ou “cracking” the softer aluminum casing.

Le “T” suffix on these bolts (Par exemple, Q1851650**T**) indicates a specific high-tensile strength class (Par exemple, 10.9) and a specialized, corrosion-resistant coating. These bolts must endure the constant, multi-axis “shear” forces from the engine’s torque. The different part numbers (-1650T vs -1670T) indicate different lengths, which are required for the different thicknesses of the transmission casing’s mounting bosses.

Using the correct, factory-specified, high-tensile flange bolts is the only way to ensure the FAW Transmission Mounting Logical Assembly remains securely attached to the gearbox. A loose or failed bolt would cause the entire transmission to become unsupported, leading to catastrophic failure. Le FAW Transmission Mounting Logical Assembly relies on this hardware.

The following table provides the complete, detailed breakdown of all 4 components identified in the ‘Transmission Mounting Logical Assembly’ diagram for the FAW CA4251P66K24T1A3E5 tractor. Ce FAW Transmission Mounting Logical Assembly is the core support structure for the gearbox.

| Mark | Partie no. | Nom de la pièce | Quantité |

|---|---|---|---|

| 1 | Q1851650T | Hex head flange bolt | 6 |

| 2 | Q1851670T | Hex head flange bolt | 4 |

| 3 | 1706051A91W | Transmission mounting left bracket | 1 |

| 4 | 1706052A91W | Transmission mounting right bracket (symmetric with left part) | 1 |

The specifications for the FAW Transmission Mounting Logical Assembly are defined by its function as the heavy-duty, torque-resisting, vibration-isolating “feet” of the gearbox. Le FAW Transmission Mounting Logical Assembly connects the transmission to the chassis.

| Vehicle Application | FAW Jiefang CA4251P66K24T1A3E5 6×4 Tracteur |

| Component Group | FAW Transmission Mounting Logical Assembly |

| Principaux composants | Support gauche (1706051A91W) & Support droit (1706052A91W) |

| Matériel (Typical) | High-Strength Cast Iron or Fabricated Steel |

| Total Fasteners | 10 (6x Q1851650T, 4x Q1851670T) |

| Fastener Type | High-Tensile Hex Head Flange Bolts |

| Mating Assembly (Châssis) | Transmission Auxiliary Mounting Crossbeam (Assemblée 323) |

| Primary Function | To connect the rear of the transmission to the flexible cushion mounts, supporting its weight and resisting torque. |

FAW parts, including the Cylinder Block Assembly, are packaged with care to ensure safe delivery. Each component is secured in protective materials to prevent damage during transit. The logistics network guarantees timely shipments worldwide, supporting efficient maintenance operations. Below is an image illustrating the standard packaging for FAW truck parts, showcasing the attention to detail in handling and storage.

This packaging approach minimizes the risk of corrosion or impact damage, ensuring that parts like the FAW Cylinder Block Assembly arrive in perfect condition. Customers can rely on FAW’s logistics for consistent quality and reliability.