Welcome to this comprehensive technical guide on the Termostato y bomba de agua FAW sistema, the complete thermal management assembly for the FAW Jiefang CA4251P66K24T1A3E5 6×4 diesel semi-trailer tractor. This system is the heart and brain of the engine’s cooling circuit.

El Termostato y bomba de agua FAW assembly is a dual-function system. The ‘Water Pump Assembly’ (1307010-81D) is the “heart,” a high-volume pump that circulates coolant, while the ‘Thermostat Assembly’ (1306010-81D) is the “brain,” a set of valves that regulates the engine’s temperature.

This guide is an essential resource for professional technicians and fleet managers. We will deconstruct the entire Termostato y bomba de agua FAW system into its smallest serviceable units, from the pump and its bracket to the dual-thermostat housing, bypass pipe, and all associated seals and fasteners.

The most significant moving part of the Termostato y bomba de agua FAW system is the ‘Water Pump Assembly’ (1307010-81D). This is a high-volume, belt-driven pump that serves as the heart of the cooling system. Its sole function is to circulate the engine’s entire coolant supply (many gallons) under pressure.

This pump is a centrifugal-type design. A pulley (driven by the engine’s main serpentine belt) spins a central shaft. On the other end of this shaft, inside the sealed pump housing, is a precisely shaped “impeller.” As this impeller spins at high speed, it draws coolant in from its center “eye” and slings it outward by centrifugal force. This action creates the pressure (típicamente 15-20 PSI) that forces the coolant through the engine block, into the cylinder head, through the Enfriador de aceite del motor FAW, and finally to the radiator.

The ‘Water Pump Assembly’ is a high-wear component. Its shaft spins on a heavy-duty, permanently-sealed bearing. Behind this bearing is a “mechanical seal” (or weep hole), which is a spring-loaded carbon and ceramic seal that prevents coolant from leaking out. A failure of either the bearing (causing a grinding noise) or the seal (causing a coolant leak from the weep hole) requires the replacement of the entire ‘Water Pump Assembly’.

This heavy pump is not bolted directly to the engine’s timing cover. It is held in place by the robust ‘Water Pump Bracket’ (1307046-81D). This bracket provides a rigid, vibration-free mounting point. The pump is secured to this bracket with its dedicated ‘Bolt-for Water Pump’ (1307019-81D). This entire sub-assembly is a key part of the Termostato y bomba de agua FAW sistema.

El “logic” of the Termostato y bomba de agua FAW system lies in its ‘Thermostat Assembly’ (1306010-81D). This parts list specifies a quantity of **two**. This indicates a dual-thermostat system, a superior design for a heavy-duty engine. Using two thermostats provides a “fail-safe” (it is highly unlikely both would fail simultaneously) and provides a much larger opening for high-volume coolant flow when the engine is hot.

A thermostat is a simple, self-contained, mechanical-thermal valve. It contains a small cylinder filled with a special wax pellet. This wax is engineered to have a precise melting point (P.EJ., 82°C / 180° F). Cuando el motor está frío, the wax is solid, and a spring holds the valve shut. This forces the water pump to circulate coolant *only* within the engine block via the ‘Small Loop Connection Pipe’ (1306023-53D). Este “bypass” loop allows the engine to warm up very quickly, reducing wear and improving emissions.

As the engine reaches its operating temperature, the wax inside the Termostato y bomba de agua FAW‘s thermostat pellets begins to melt and expand. This expansion pushes a small piston, which overcomes the spring pressure and opens the main valve. This action closes the bypass loop and simultaneously opens the “main loop,” allowing the hot coolant to flow out of the engine and to the radiator to be cooled. This constant, automatic modulation of coolant flow is what keeps the engine at its perfect operating temperature.

The dual ‘Thermostat Assembly’ units are housed in a large, central casting. The parts list identifies this as two main pieces: the ‘Thermostat Seat’ (1306021-51B) and the ‘Thermostat Upper Cover’ (1306013-81D). El “Asiento” is the main housing that bolts to the engine head and contains the passages for the bypass and radiator loops. The two thermostats (1306010-81D) are dropped into this seat, each sealed by its own ‘Seal Ring-Thermostat’ (1306011-29D).

The ‘Thermostat Upper Cover’ then bolts on top, sealing the thermostats inside. This cover is the main “outlet” of the Termostato y bomba de agua FAW sistema, where the large radiator hose attaches. This cover is sealed to the ‘Thermostat Seat’ by a large O-ring or gasket (not explicitly listed but part of the assembly).

The ‘Small Loop Connection Pipe’ (1306023-53D) is the external bypass hose mentioned earlier. This pipe connects the thermostat housing directly back to the inlet side of the ‘Water Pump Assembly’ (1307010-81D). This is the path the coolant takes when the engine is cold. The ‘Hex Head Tapered Screw Plug’ (CQ61801) is used to seal a diagnostic or drain port on this housing. The entire housing of the Termostato y bomba de agua FAW is a complex, multi-part component.

The entire Termostato y bomba de agua FAW system manages hot, pressurized coolant, making its seals and fasteners critical. The parts list calls for several ‘Hydraulic pneumatic O-ring rubber seals’ (CQ7343412C, CQ343530C, CQ345462C). These are high-temperature, glycol-resistant O-rings used to seal the various pipe connections and plugs, such as the ‘Small Loop Connection Pipe’.

The ‘Seal Ring-Thermostat’ (1306011-29D) is a specialized rubber ring that fits around the rim of the thermostat itself, forcing all coolant to pass *through* the valve, not around it. A failure of this small seal will cause the engine to warm up very slowly.

The system is held together by a specific set of fasteners. ‘Bolt-for Thermostat’ (1306062-81D and 1306063-81D) are used to secure the ‘Thermostat Upper Cover’ to the ‘Thermostat Seat’. ‘Hex flange bolts’ (Q1840820, Q1841065) and ‘Combination Bolts’ (CQ1461025, CQ1461055) are used to secure the ‘Water Pump Bracket’ and the ‘Thermostat Seat’ to the engine block itself. Using the correct length and grade of these Termostato y bomba de agua FAW fasteners is essential to prevent cracking the aluminum housings or failing to achieve a proper gasket seal.

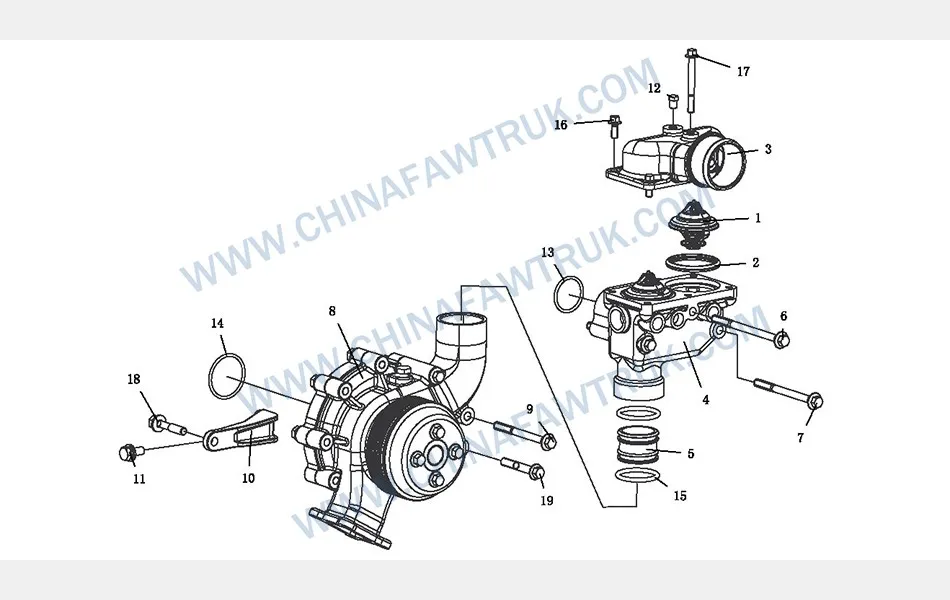

The following table provides the complete, detailed breakdown of all components identified in the ‘Thermostat and Water Pump’ diagram for the FAW CA4251P66K24T1A3E5 tractor. A complete service of the Termostato y bomba de agua FAW requires replacing all seals and O-rings.

| Mark | Número de pieza. | Nombre de la pieza | Cantidad |

|---|---|---|---|

| 1 | 1306010-81D | Ensamblaje del termostato | 2 |

| 2 | 1306011-29D | Seal Ring-Thermostat | 2 |

| 3 | 1306013-81D | Thermostat Upper Cover | 1 |

| 4 | 1306021-51B | Thermostat Seat | 1 |

| 5 | 1306023-53D | Small Loop Connection Pipe | 1 |

| 6 | 1306062-81D | Bolt-for Thermostat | 1 |

| 7 | 1306063-81D | Bolt-for Thermostat | 2 |

| 8 | 1307010-81D | Water Pump Assembly | 1 |

| 9 | 1307019-81D | Bolt-for Water Pump | 2 |

| 10 | 1307046-81D | Water Pump Bracket | 1 |

| 11 | CQ1461025 | Perno combinado | 1 |

| 12 | CQ61801 | Hex Head Tapered Screw Plug | 1 |

| 13 | CQ7343412C | Hydraulic pneumatic O-ring rubber seal | 2 |

| 14 | CQ343530C | Hydraulic pneumatic O-ring rubber seal | 1 |

| 15 | CQ345462C | Hydraulic pneumatic O-ring rubber seal | 2 |

| 16 | Q1840820 | Hex flange bolt, coarse rod (Tipo estándar) | 5 |

| 17 | CQ1461055 | Perno combinado | 1 |

| 18 | Q1841065 | Hex flange bolt, coarse rod (Tipo estándar) | 2 |

The specifications for the Termostato y bomba de agua FAW are defined by its dual-system design, which provides both high-volume circulation (pump) and precise thermal regulation (termostato). The entire Termostato y bomba de agua FAW system is essential for engine health.

| Vehicle Application | FAW Jiefang CA4251P66K24T1A3E5 6×4 Tractor |

| Component Group | Termostato y bomba de agua FAW |

| Water Pump Assembly | 1incógnita (Número de pieza. 1307010-81D), Centrifugal Type |

| Water Pump Mount | 1x Water Pump Bracket (1307046-81D) |

| Thermostat System | Dual Thermostat Assembly (2x 1306010-81D) |

| Thermostat Housing | Comprised of Seat (1306021-51B) and Upper Cover (1306013-81D) |

| Bypass Circuit | 1x Small Loop Connection Pipe (1306023-53D) |

| Main Thermostat Seals | 2x Seal Ring-Thermostat (1306011-29D) |

| Pipe Seals | 5x O-rings (CQ734-series) |

| Primary Function | To circulate coolant (pump) and maintain optimal engine operating temperature (termostato). |

FAW parts, including the Cylinder Block Assembly, are packaged with care to ensure safe delivery. Each component is secured in protective materials to prevent damage during transit. The logistics network guarantees timely shipments worldwide, supporting efficient maintenance operations. Below is an image illustrating the standard packaging for FAW truck parts, showcasing the attention to detail in handling and storage.

This packaging approach minimizes the risk of corrosion or impact damage, ensuring that parts like the FAW Cylinder Block Assembly arrive in perfect condition. Customers can rely on FAW’s logistics for consistent quality and reliability.