Welcome to the complete technical guide for the FAW Piston Connecting Rod Assembly, the heart of the internal combustion engine for the FAW Jiefang CA4251P66K24T1A3E5 6×4 diesel semi-trailer tractor. This is the rotating and reciprocating assembly that converts combustion pressure into torque.

This entire rotating and reciprocating group is what defines the engine’s power and durability. The FAW Piston Connecting Rod Assembly is the complete set of all six matched piston and rod groups. A failure in any part of this system is critical.

This guide is an essential resource for professional engine rebuilders, machine shops, and fleet technicians. We will deconstruct the entire FAW Piston Connecting Rod Assembly from top to bottom, breaking down each of the six assemblies into their smallest serviceable units—from the piston rings and pins to the connecting rod bearing shells.

The ‘Piston’ (1004011-81Д) is the “crown” of the FAW Piston Connecting Rod Assembly. The parts list calls for six, one for each cylinder. This component is responsible for forming the lower half of the combustion chamber and harnessing the immense force of the diesel power stroke. It is cast from a high-strength, low-expansion hypereutectic aluminum alloy, designed to be both lightweight to reduce reciprocating mass and incredibly strong to resist the high temperatures and pressures.

The design of the piston face is critical. In a direct-injection diesel, the top of the piston features a complex “bowl.” The shape of this bowl is not arbitrary; it is precisely engineered to induce “swirl” as the air is compressed, ensuring the injected fuel mixes perfectly with the hot, compressed air for a complete and efficient burn. This material and design choice is critical for the longevity of the FAW Piston Connecting Rod Assembly.

To survive in this environment, these pistons feature an internal “cooling gallery,” a hollow channel cast into the piston crown, just behind the ring lands. Oil jets in the engine block spray a continuous stream of cool oil into this gallery. This oil absorbs the intense heat from the piston crown and rings, then drains back to the sump. This cooling action is essential for preventing the piston from overheating, expanding, and seizing in the cylinder, and it is a key feature of the modern FAW Piston Connecting Rod Assembly. A failure in this cooling circuit will quickly destroy the piston, making the integrity of the entire FAW Piston Connecting Rod Assembly compromised.

The piston rings are arguably the most critical sealing components within the entire FAW Piston Connecting Rod Assembly. This parts list specifies a three-ring pack for each of the six pistons:

The ‘First Compression Ring’ is the top ring. Its sole purpose is to seal the cylinder, containing the white-hot, high-pressure combustion gases (which can exceed 2500 PSI) within the combustion chamber. It is precision-machined from high-strength ductile iron or steel and often has a “barrel” face and a corrosion-resistant coating (like plasma-moly) to survive the extreme heat and pressure. This is the primary seal for the FAW Piston Connecting Rod Assembly.

The ‘Second Compression Ring’ has a dual role. It acts as a secondary combustion seal, catching any gases that “blow by” the top ring. Однако, its primary function is oil control. It is often a “taper-faced” или “scraper” дизайн, which effectively scrapes the majority of the lubricating oil off the cylinder wall on the piston’s downstroke, preventing it from being drawn up into the combustion chamber and burned. A worn second ring on the FAW Piston Connecting Rod Assembly is a very common cause of excessive oil consumption and blue smoke.

The ‘I-profile Steel Oil Ring Assembly’ is the bottom ring and the final line of defense for oil control. This is a modern, complex, three-piece assembly. It consists of two very thin, flexible steel “rails” that ride against the cylinder wall, separated by a central “expander-spacer.” The expander pushes the two rails outward with a precise amount of tension. This design offers superior “conformability” to the cylinder wall, scraping off the final film of oil with minimal friction. This part of the FAW Piston Connecting Rod Assembly is key to the engine’s long-term efficiency and emissions control.

The health of this ring pack determines the health of the engine. A worn ring pack on any of the six FAW Piston Connecting Rod Assembly units will result in low compression (hard starting, low power), high oil consumption, and excessive crankcase “blow-by.” A full rebuild of the FAW Piston Connecting Rod Assembly always includes a new, complete set of piston rings.

The ‘Connecting Rod Assembly’ (1004020A81D) is the “arm” that connects the piston (via the piston pin) to the crankshaft. It is the namesake component of the FAW Piston Connecting Rod Assembly. This component must withstand incredible, reversing stresses: it is violently pushed down by the combustion stroke and just as violently pulled back up by the exhaust stroke.

To handle this, these rods are not cast; they are drop-forged from a single billet of high-strength steel. The forging process aligns the steel’s grain structure, giving it immense fatigue resistance. They are typically an “I-beam” cross-section, which provides the maximum possible strength and rigidity for the lowest weight. This is the standard for any heavy-duty FAW Piston Connecting Rod Assembly.

A key feature of this modern ‘Connecting Rod Assembly’ is its “fracture-split” big-end cap. The rod and its bearing cap are forged as a single piece. The main bolt holes are drilled and tapped, and then the cap is literally “cracked” или “snapped” off the rod using a hydraulic press. This creates a perfectly matched, irregular, interlocking surface that is far stronger and more resistant to shifting under load than any machined flat surface could ever be. This strength is vital to the entire FAW Piston Connecting Rod Assembly.

Because they are a matched set, a connecting rod cap can *never* be interchanged with another rod, not even one from the same engine. The entire `Connecting Rod Assembly` is a balanced and matched unit, and its integrity is fundamental to the proper operation of the FAW Piston Connecting Rod Assembly.

The ‘Piston Pin’ (1004018-81Д), often called a “wrist pin,” is the component that forms the pivot between the piston and the “small end” of the connecting rod. It’s a hollow, thick-walled tube made of extremely hard, case-hardened steel, polished to a mirror finish. This pin links the two main parts of the FAW Piston Connecting Rod Assembly.

This system uses a “full-floating” дизайн. This means the pin is not pressed into either the rod or the piston. It is free to rotate, или “float,” in both the connecting rod’s small-end bushing and the piston’s pin boss. This design allows for better load distribution and reduced wear, and it is superior for the longevity of the FAW Piston Connecting Rod Assembly.

To prevent this floating pin from sliding sideways and gouging the cylinder wall, it is secured by two ‘Piston Pin Circlips’ (1004019-81Д). The parts list calls for 12 clips, which is two per piston (one on each side). These small spring-steel clips snap into grooves inside the piston’s pin boss. These small clips are a critical, non-reusable part of the FAW Piston Connecting Rod Assembly.

The ‘Connecting Rod Upper Bearing Shell’ (1004026-81Д) and ‘Connecting Rod Lower Bearing Shell’ (1004028-81Д) are the final components of the FAW Piston Connecting Rod Assembly. These two “half-shells” come together to form the “big end” bearing that rides on the crankshaft’s rod journal.

They are not identical. The “upper” shell, which sits in the connecting rod itself, is the one that endures the colossal force of the combustion stroke. Как таковой, it is often made of a more robust, harder material than the lower shell, which only carries the “inertial” load of the FAW Piston Connecting Rod Assembly on the upstroke.

These are precision, multi-layer components with a steel backing for strength and a thin, soft, “babbitt” (tin-alloy) or similar overlay. The crankshaft does not ride on the metal; it rides on a hydrodynamic film of oil, just thousandths of an inch thick. This oil is supplied by a hole in the crankshaft. A worn bearing in the FAW Piston Connecting Rod Assembly will cause this oil clearance to become too large, resulting in a “rod knock” sound.

Measuring the oil clearance of the FAW Piston Connecting Rod Assembly with Plastigage during assembly is one of the most critical steps in an engine rebuild. The precision of these shells, along with the rod and cap, is what ensures a quiet, long-lasting engine.

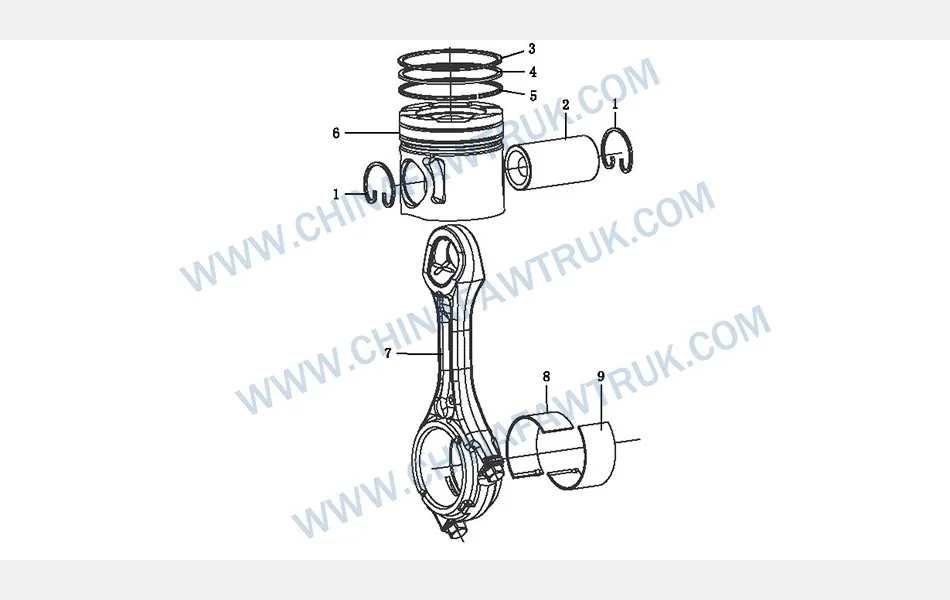

The following table provides the complete, detailed breakdown of all components identified in the ‘Piston Connecting Rod Assembly’ diagram for the FAW CA4251P66K24T1A3E5 tractor. Using genuine parts for your FAW Piston Connecting Rod Assembly is crucial for ensuring proper balance, fit, and engine longevity.

| Mark | Часть №. | Наименование | Количество |

|---|---|---|---|

| 1 | 1004019-81Д | Piston Pin Circlip | 12 |

| 2 | 1004018-81Д | Поршневая булавка | 6 |

| 3 | 1004012-81Д | First Compression Ring | 6 |

| 4 | 1004013-81Д | Second Compression Ring | 6 |

| 5 | 1004030-81Д | I-profile Steel Oil Ring Assembly | 6 |

| 6 | 1004011-81Д | Поршень | 6 |

| 7 | 1004020A81D | Шатун в сборе | 6 |

| 8 | 1004026-81Д | Connecting Rod Upper Bearing Shell | 6 |

| 9 | 1004028-81Д | Connecting Rod Lower Bearing Shell | 6 |

The specifications for the FAW Piston Connecting Rod Assembly are defined by its matched, balanced design for a 6-cylinder diesel engine. Each FAW Piston Connecting Rod Assembly is a precision-matched set.

| Vehicle Application | FAW Jiefang CA4251P66K24T1A3E5 6×4 Tractor |

| Component Group | FAW Piston Connecting Rod Assembly |

| Quantity per Engine | 6 complete assemblies |

| Piston Type | Hypereutectic Aluminum w/ Cooling Gallery (1004011-81Д) |

| Connecting Rod Type | Forged Steel, Fracture-Split Cap (1004020A81D) |

| Piston Pin Type | Full-Floating (1004018-81Д) w/ 2 Circlips (1004019-81Д) |

| Ring Pack | 3-Кольцо: 1x Compression (1004012-81Д), 1x Scraper (1004013-81Д), 1x Oil Control (1004030-81Д) | Two

| Rod Bearings | Multi-Layer Shells: 1x Upper (1004026-81Д), 1x Lower (1004028-81Д) |

| Primary Function | Converts linear force of combustion into rotational force at the crankshaft. |

FAW parts, including the Cylinder Block Assembly, are packaged with care to ensure safe delivery. Each component is secured in protective materials to prevent damage during transit. The logistics network guarantees timely shipments worldwide, supporting efficient maintenance operations. Below is an image illustrating the standard packaging for FAW truck parts, showcasing the attention to detail in handling and storage.

This packaging approach minimizes the risk of corrosion or impact damage, ensuring that parts like the FAW Cylinder Block Assembly arrive in perfect condition. Customers can rely on FAW’s logistics for consistent quality and reliability.