Welcome to this critical technical guide on the FAW Oil Filter asamblea (Número de pieza. 1012010-54W.). This is one of the most vital, life-preserving components for the high-performance diesel engine in the FAW Jiefang CA4251P66K24T1A3E5 6×4 semi-trailer tractor.

The function of the FAW Oil Filter is to continuously “clean” the engine’s lifeblood—its oil. As the engine runs, the oil becomes contaminated with abrasive metal particles from wear, soot from combustion, and sludge from oil breakdown. El FAW Oil Filter is designed to trap and remove these contaminants, preventing them from destroying the engine’s precision-tolerance bearings and components.

This guide is an essential resource for professional technicians, fleet maintenance managers, and parts specialists. The parts list for this assembly is deceptively simple, but it represents a complex system. We will deconstruct the function, diseño, and critical importance of the FAW Oil Filter assembly to ensure every service is performed to exact factory standards.

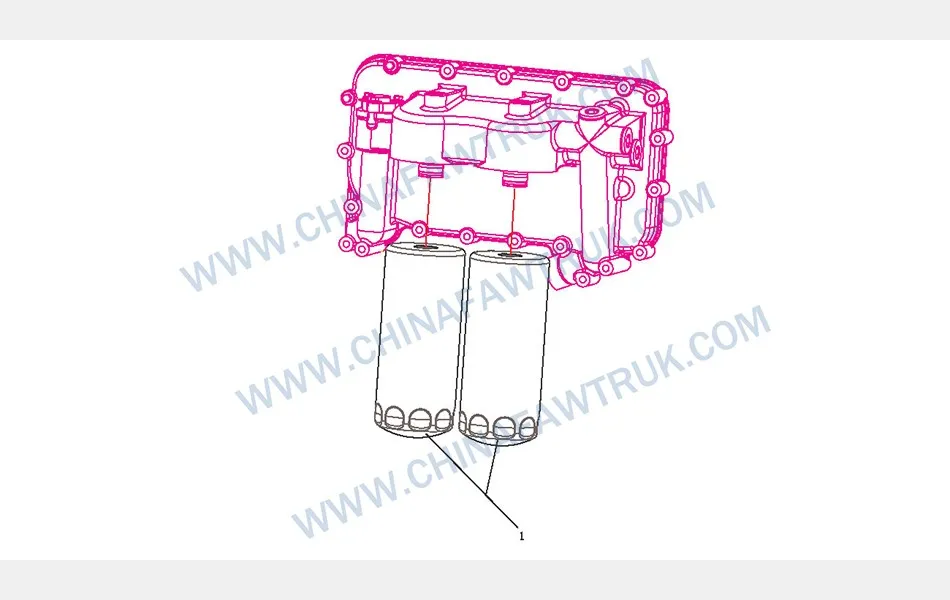

The parts list for the FAW Oil Filter specifies a quantity of two. This is not for a single oil change with a spare; this engine requires **two** filters to be installed simultaneously. This dual-filter setup is a hallmark of a heavy-duty diesel engine and is critical for two reasons: flow rate and filtration capacity.

A large diesel engine like this one has a very high-volume oil pump, circulating 30-40 liters of oil (or more) many times per minute. A single, standard-sized FAW Oil Filter would create too much restriction, o “pressure drop,” for this high flow rate. By using two filters in a parallel circuit, the oil pump can push the same volume of oil through the system with half the effort, ensuring full oil pressure and flow reaches the bearings even on a cold start when the oil is thick.

This dual setup also doubles the filtration capacity. Diesel engine oil must handle a massive amount of soot from combustion. The dual FAW Oil Filter system provides twice the media surface area to trap and hold this soot, which is the key to achieving the long oil-change intervals required for a commercial tractor.

In many heavy-duty dual-filter systems, the two filters are not identical in function. The system often operates on a “full-flow” y “bypass” logic. The first FAW Oil Filter is the **full-flow filter**. 100% of the oil from the oil pump is forced through this filter. Its job is to catch all large, damaging particles (P.EJ., 25-40 microns) without creating too much restriction.

The second FAW Oil Filter is often a **bypass filter**. This filter is on a separate, parallel circuit and receives only a small percentage (perhaps 10%) of the total oil flow. Because it handles a low volume, its filter media can be incredibly dense, allowing it to filter out extremely fine particles (P.EJ., 5-10 microns). This bypass FAW Oil Filter is specifically designed to remove fine soot and sludge that the main full-flow filter cannot.

This dual-logic system provides the best of both worlds: 100% of the oil is cleaned of large, dangerous debris (full-flow), while a portion of the oil is “polished” to an ultra-clean state (bypass). This combination is what keeps the entire oil volume clean and extends its service life, making the FAW Oil Filter system far more advanced than a simple, single-filter setup.

While the FAW Oil Filter (1012010-54W.) is listed as a single part, this “asamblea” is a complex system of five key components working in unison inside a steel canister.

**1. The Steel Canister and Base Plate:** The outer housing is a thick-walled steel canister designed to withstand oil pressures that can exceed 150 PSI. The heavy steel base plate is where the mounting threads and the gasket are located. This is the structural backbone of the FAW Oil Filter.

**2. The Filter Media:** This is the heart of the FAW Oil Filter. It is not paper, but a high-efficiency synthetic blend or “micro-glass” media. This media is precisely pleated to maximize the total surface area, allowing it to hold a large volume of soot and debris before it becomes restrictive.

**3. The Anti-Drainback Valve:** This is a nitrile-rubber flap or “umbrella” valve located just inside the small inlet holes on the base plate. When the engine is shut off, this valve snaps shut, preventing all the oil from draining out of the FAW Oil Filter and back into the oil pan. This ensures that on the next startup, the oil pump delivers *instantly* pressurized oil to the engine, rather than having to waste critical seconds refilling the filters.

**4. The Internal Bypass Valve:** Deep inside the FAW Oil Filter is a spring-loaded pressure relief valve. Its function is to save the engine. If the filter media becomes completely clogged with debris, or if the oil is thick as honey on a sub-zero start, the pressure inside the filter will spike. This valve will then open, allowing the oil to *bypass* the filter media and flow directly to the engine. Unfiltered oil is bad, but *no oil* is catastrophic. This valve ensures the engine is never starved of oil, making it a critical safety feature of the FAW Oil Filter.

**5. The Main Gasket:** The square-cut or O-ring rubber gasket on the base plate of the FAW Oil Filter provides the final seal against the engine block. It must be clean, flexible, and lightly lubricated with new oil before installation to prevent it from pinching, tearing, o “double-gasketing” (a common and disastrous installation error).

El FAW Oil Filter is a primary maintenance item. Replacing both (1012010-54W.) units at every specified oil change interval is the single most important preventative maintenance task an owner or operator can perform.

Using a non-genuine FAW Oil Filter is extremely high-risk. A counterfeit filter may save a small amount of money, but it almost certainly has inferior filter media (allowing large particles through), a weak anti-drainback valve (causing dry starts), or an incorrectly calibrated bypass valve (either opening too soon and not filtering, or not opening at all and starving the engine).

Proper installation is critical. The old FAW Oil Filter must be removed, and the technician must ensure the old gasket came off with it. The mounting surface on the engine block must be wiped clean. A light film of new, clean engine oil must be applied to the gasket of the new FAW Oil Filter. The filter is then spun on *by hand* until it makes contact, and then tightened an additional 3/4 a 1 full turn, as per the instructions printed on the canister. Over-tightening with a wrench can damage the threads or gasket, while under-tightening will cause a massive, high-pressure oil leak.

The following table provides the complete, detailed breakdown of all components identified in the ‘Oil Filter’ diagram for the FAW CA4251P66K24T1A3E5 tractor. Este FAW Oil Filter is the key to engine longevity.

| Mark | Número de pieza. | Nombre de la pieza | Cantidad |

|---|---|---|---|

| 1 | 1012010-54W. | Oil Filter Assembly | 2 |

The specifications for the FAW Oil Filter system are defined by its dual-filter design, engineered for high-capacity, high-flow, and high-efficiency filtration in a heavy-duty diesel environment.

| Vehicle Application | FAW Jiefang CA4251P66K24T1A3E5 6×4 Tractor |

| Component Group | FAW Oil Filter |

| Part Number | 1012010-54W. |

| Quantity per Engine | 2 |

| Filter Type | Spin-on Canister |

| System Type | Dual-Filter Assembly (Likely Full-Flow/Bypass Configuration) |

| Filter Media | High-Efficiency Synthetic/Glass-Blend Media |

| Internal Feature 1 | Anti-Drainback Valve (Nitrile Rubber) |

| Internal Feature 2 | Internal Pressure Bypass Valve (Spring-Loaded) |

| Seal Type | Molded Elastomer Base Gasket (O-ring or Square-Cut) |

| Primary Function | Removes abrasive particles, soot, and sludge from engine oil to protect all internal components. |

FAW parts, including the Cylinder Block Assembly, are packaged with care to ensure safe delivery. Each component is secured in protective materials to prevent damage during transit. The logistics network guarantees timely shipments worldwide, supporting efficient maintenance operations. Below is an image illustrating the standard packaging for FAW truck parts, showcasing the attention to detail in handling and storage.

This packaging approach minimizes the risk of corrosion or impact damage, ensuring that parts like the FAW Cylinder Block Assembly arrive in perfect condition. Customers can rely on FAW’s logistics for consistent quality and reliability.