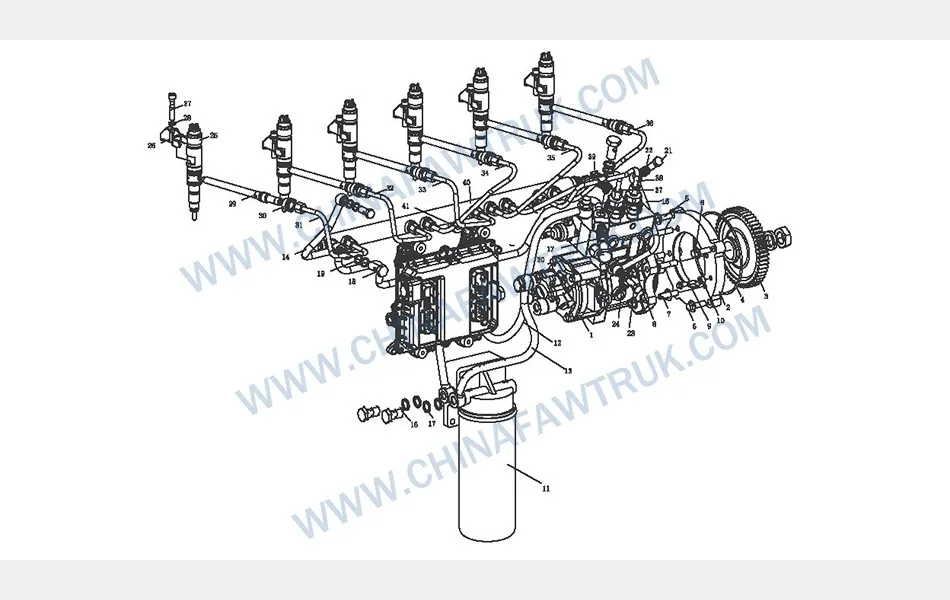

Welcome to this expert, in-depth guide to the FAW Fuel Supply System, the complete “high-pressure common rail” (HPCR) system for the FAW Jiefang CA4251P66K24T1A3E5 6×4 diesel semi-trailer tractor. This is the single most complex and precise system in the entire powertrain.

ال FAW Fuel Supply System is responsible for drawing fuel from the tank, filtering it to a microscopic level, pressurizing it to over 30,000 PSI, and then injecting it with millisecond-precision directly into the engine’s cylinders. This system’s performance dictates engine power, اقتصاد الوقود, and emissions.

This guide is an essential resource for professional diesel technicians, fleet managers, and parts specialists. We will deconstruct the entire FAW Fuel Supply System, from the low-pressure lift circuit and fine filter to the high-pressure pump, the common rail, and the six individual injector lines, breaking it down to every last serviceable nut, bolt, and seal.

The heart of the FAW Fuel Supply System is the ‘High pressure fuel pump assembly’ (1111010-73د). This is an incredibly precise, high-torque pump that draws in low-pressure, filtered diesel and compresses it to the 30,000+ PSI (2000+ bar) required by the common rail. It is a “common rail” مضخة, meaning its job is only to generate pressure; it is not timed to the injectors.

This pump is a gear-driven component, integrated directly into the engine’s timing. The ‘Injection pump drive gear’ (1111216-81د) meshes with the engine’s timing gear train, ensuring the pump is always turning when the engine is. It is rigidly mounted to the engine block via the ‘High pressure fuel pump connecting flange’ (1111228-81د). This mounting is precisely located by a ‘Dowel pin’ (1111226-59د) and ‘Sleeve’ (1111227-59د), then secured with ‘Stud bolts’ (CQ1201030) and ‘Hex flange nuts’ (CQ39610).

This pump is also lubricated by engine oil. The ‘Banjo bolt-injection pump oil inlet’ (1104076-73د) and ‘Engine oil inlet pipe assembly’ (1104070-81د) supply clean oil to its internal bearings. This makes the FAW Fuel Supply System‘s main pump a complex, mission-critical component that relies on both clean fuel and clean oil to survive.

If the pump is the heart, the ‘High pressure rail assembly’ (1129110-81د) is the brain. This is the “common rail” نفسها. It is a thick-walled, forged steel tube that acts as a pressure accumulator. Its job is to store the high-pressure fuel from the pump and distribute it evenly to all six cylinders.

This rail is fed by two separate pipes from the pump: ‘High pressure oil pipe assembly I’ (1129070-81د) and ‘High pressure oil pipe assembly II’ (1129080-81د). This dual-feed design ensures the rail’s pressure remains stable, even under high load.

The rail is mounted to the engine head with ‘Hex flange bolts’ (س1840835). It is the central distribution hub for the entire high-pressure side of the FAW Fuel Supply System. It also typically houses the master fuel pressure sensor and a pressure relief valve, which are the primary inputs for the engine’s ECU.

This module contains the “توصيل” components of the FAW Fuel Supply System. The system uses six ‘Injector assembly’ (1112010-51ب) وحدات. These are not simple nozzles; they are highly advanced, electronically controlled (solenoid or piezo) الحقن. They receive the “fire” signal from the ECU, opening for just milliseconds to blast a fine, atomized mist of fuel into the combustion chamber.

Each injector is fed from the common rail by its own individual, pre-bent steel pipe. These are the ‘First cylinder high pressure oil pipe assembly’ (1129010-81د) through the ‘Sixth cylinder high pressure oil pipe assembly’ (1129060-81د). These six pipes are single-use “crush-fit” lines and must be replaced if ever loosened to ensure a leak-free seal. They are the arteries of the FAW Fuel Supply System.

The injectors themselves are mounted deep inside the cylinder head. A ‘High pressure oil pipe connector assembly’ (1112030-81د) with an ‘Intermediate compression nut’ (1112031-29د) forms the high-pressure seal at the injector’s inlet. Each injector is held down with extreme force by an ‘Injector clamp’ (1112011-81د), an ‘Injector clamp bolt’ (1112013-81د), and a ‘Spherical washer’ (1112014-81د). This clamp-and-bolt system is critical to prevent the injector from being blown out of the head by combustion pressure. This entire sub-assembly is the “business end” of the FAW Fuel Supply System.

The high-pressure pump can only work if it is fed a constant supply of clean, low-pressure fuel. This is the job of the low-pressure side of the FAW Fuel Supply System. أ (likely) mechanical lift pump, integrated into the main HP pump assembly, pulls fuel from the tank.

This fuel travels through the ‘Inlet pipe assembly-transfer pump to fine filter’ (1104030A51B). This line is secured by ‘Banjo bolt-transfer pump inlet/outlet’ (1104036-73د) and sealed by ‘Gasket rings’ (CQ72316T5).

This pipe feeds the ‘Fuel fine filter assembly’ (1117010-81د), أيّ (as detailed in our previous guide) is the critical component for removing water and microscopic debris. This is the “kidney” of the FAW Fuel Supply System.

After the fuel is cleaned, it flows through the ‘Inlet pipe assembly-fine filter to high pressure pump’ (1104040A51B), which is sealed with ‘Banjo bolts’ (1117038-60د) and gaskets. This pipe delivers the clean, low-pressure fuel that the HP pump will compress. The entire FAW Fuel Supply System depends on this low-pressure loop being airtight and leak-free.

ال FAW Fuel Supply System has two other vital “plumbing” دوائر. First, the ‘Return pipe assembly’ (1104050-81د) is the fuel return line. HPCR injectors and the pressure relief valve on the rail “leak” أو “bypass” a certain amount of fuel to function. هذا “return” fuel is collected and sent back to the tank via this pipe, completing the fuel circuit.

Second, as mentioned, the high-pressure pump is lubricated by engine oil, not diesel fuel. The ‘Engine oil inlet pipe assembly’ (1104070-81د) provides this oil. It is a high-pressure line sealed with ‘Banjo bolt-engine oil lube pipe assembly’ (1104076-53د) and ‘Gasket rings’ (CQ72312T5). After lubricating the pump, the oil exits via a ‘Banjo bolt-engine oil return pipe’ (1104073-D6). This entire oiling sub-system is crucial to the life of the FAW Fuel Supply System‘s main pump.

The following table provides the complete, detailed breakdown of all components identified in the ‘Fuel Supply System’ diagram for the FAW CA4251P66K24T1A3E5 tractor. هذا FAW Fuel Supply System is a high-precision, zero-tolerance assembly.

| Mark | الجزء لا. | جزء اسم | كمية |

|---|---|---|---|

| 1 | 1111010-73د | تجميع مضخة الوقود ذات الضغط العالي | 1 |

| 2 | 1111228-81د | High pressure fuel pump connecting flange | 1 |

| 3 | 1111216-81د | Injection pump drive gear | 1 |

| 4 | Q073431550C | Hydraulic pneumatic O-ring rubber seal | 1 |

| 5 | س1841030 | Hex flange bolt, coarse rod (نوع قياسي) | 2 |

| 6 | س1841040 | Hex flange bolt, coarse rod (نوع قياسي) | 2 |

| 7 | CQ1201030 | مسمار الترباس | 4 |

| 8 | CQ39610 | Hex flange nut | 4 |

| 9 | 1111226-59د | Dowel pin | 1 |

| 10 | 1111227-59د | كم | 1 |

| 11 | 1117010-81د | مجموعة مرشح الوقود غرامة (as-per-sample) | 1 |

| 12 | 1104030A51B | Inlet pipe assembly-transfer pump to fine filter (as-per-sample) | 1 |

| 13 | 1104040A51B | Inlet pipe assembly-fine filter to high pressure pump (as-per-sample) | 1 |

| 14 | 1104050-81د | إرجاع مجموعة الأنابيب (as-per-sample) | 1 |

| 15 | 1104070-81د | Engine oil inlet pipe assembly (as-per-sample) | 1 |

| 16 | 1104036-73د | Banjo bolt-transfer pump inlet/outlet | 6 |

| 17 | CQ72316T5 | Gasket ring | 14 |

| 18 | 1104073-D6 | Banjo bolt-engine oil return pipe | 2 |

| 19 | CQ72314T5 | Gasket ring | 4 |

| 20 | 1117038-60د | Banjo bolt | 1 |

| 21 | 1104076-53د | Banjo bolt-engine oil lube pipe assembly | 1 |

| 22 | CQ72312T5 | Gasket ring | 2 |

| 23 | 1104076-73د | Banjo bolt-injection pump oil inlet | 1 |

| 24 | CQ72310T5 | Gasket ring | 2 |

| 25 | 1112010-51ب | مجموعة الحاقن | 6 |

| 26 | 1112011-81د | Injector clamp | 6 |

| 27 | 1112013-81د | Injector clamp bolt | 6 |

| 28 | 1112014-81د | غسالة كروية | 6 |

| 29 | 1112030-81د | High pressure oil pipe connector assembly | 6 |

| 30 | 1112031-29د | Intermediate compression nut-high pressure pipe connector | 1 |

| 31 | 1129010-81د | First cylinder high pressure oil pipe assembly | 1 |

| 32 | 1129020-81د | Second cylinder high pressure oil pipe assembly | 1 |

| 33 | 1129030-81د | Third cylinder high pressure oil pipe assembly | 1 |

| 34 | 1129040-81د | Fourth cylinder high pressure oil pipe assembly | 1 |

| 35 | 1129050-81د | Fifth cylinder high pressure oil pipe assembly | 1 |

| 36 | 1129060-81د | Sixth cylinder high pressure oil pipe assembly | 1 |

| 37 | 1129070-81د | High pressure oil pipe assembly I – HP pump to HP rail | 1 |

| 38 | 1129080-81د | High pressure oil pipe assembly II – HP pump to HP rail | 1 |

| 39 | 1129090-73د | High pressure oil pipe clamp assembly I | 1 |

| 40 | 1129110-81د | High pressure rail assembly | 1 |

| 41 | س1840835 | Hex flange bolt, coarse rod (نوع قياسي) | 3 |

The specifications for the FAW Fuel Supply System are defined by its function as a high-pressure, electronically controlled diesel injection system. The entire FAW Fuel Supply System is a high-precision, zero-tolerance assembly.

| Vehicle Application | FAW Jiefang CA4251P66K24T1A3E5 6×4 جرار |

| Component Group | FAW Fuel Supply System |

| System Type | High-Pressure Common Rail (HPCR) |

| High Pressure Pump | 1x (الجزء لا. 1111010-73د), Gear-Driven |

| High Pressure Rail | 1x (الجزء لا. 1129110-81د), Dual-Feed |

| الحقن | 6x Electronic Injector Assemblies (1112010-51ب) |

| Injector Lines | 6x Individual Steel Pipes (1129010-81D to 1129060-81D) |

| Pump Lubrication | Pressurized Engine Oil (1104070-81د) |

| Filtration (Sub-Assembly) | 1x Fuel Fine Filter Assembly (1117010-81د) |

| Primary Function | To filter, pressurize (ل 30,000+ PSI), and inject diesel fuel with precision timing. |

FAW parts, including the Cylinder Block Assembly, are packaged with care to ensure safe delivery. Each component is secured in protective materials to prevent damage during transit. The logistics network guarantees timely shipments worldwide, supporting efficient maintenance operations. Below is an image illustrating the standard packaging for FAW truck parts, showcasing the attention to detail in handling and storage.

This packaging approach minimizes the risk of corrosion or impact damage, ensuring that parts like the FAW Cylinder Block Assembly arrive in perfect condition. Customers can rely on FAW’s logistics for consistent quality and reliability.