Welcome to this critical guide on the Топливный фильтр тонкой очистки FAW (Часть №. 1117010-81Д), the most important line of defense for the high-pressure fuel injection system on the FAW Jiefang CA4251P66K24T1A3E5 6×4 diesel semi-trailer tractor.

This component is not just a simple screen; the modern Топливный фильтр тонкой очистки FAW is an advanced multi-stage coalescing and filtration unit. Its sole purpose is to remove microscopic abrasive particles and, most importantly, all traces of water from the diesel fuel before it reaches the multi-thousand-PSI common rail pump and injectors.

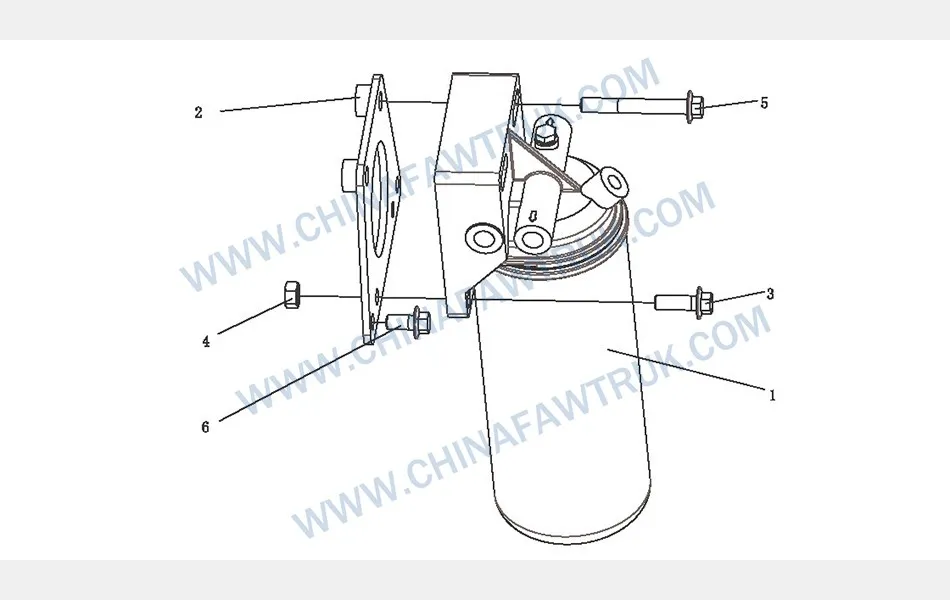

This guide is an essential resource for professional technicians, fleet maintenance managers, and parts specialists. We will deconstruct the entire Топливный фильтр тонкой очистки FAW сборка, including its permanent mounting base, its replaceable cartridge, and its rigid support bracket, down to the last serviceable nut and bolt.

The parts list for Mark 1 details the three key components of the Топливный фильтр тонкой очистки FAW system. The parent part is the ‘Fuel Fine Filter Assembly’ (1117010-81Д), which is the complete unit. This assembly is comprised of two distinct serviceable parts:

**1. The ‘Fuel Fine Filter Base Assembly’ (1117020-81Д):** This is the permanent, non-replaceable “head” of the system. It is a precision-cast aluminum housing that bolts to the main bracket. This base contains the fuel inlet and outlet ports, the threaded mount for the filter element, and likely the ports for a fuel pre-heater and a “Water-in-Fuel” (WiF) датчик. This base is the control hub for the entire Топливный фильтр тонкой очистки FAW.

**2. The ‘Fuel Fine Filter Element Assembly’ (1117050-81Д):** This is the “service part” or the cartridge. This is the replaceable, spin-on canister that contains the actual filter media. During a service, this element is the only part of the Топливный фильтр тонкой очистки FAW (1117010-81Д) that is discarded and replaced. Its design is crucial for protecting the engine.

Understanding this relationship is key: the Base (7020) and the Element (7050) combine to create the complete ‘Fuel Fine Filter Assembly’ (7010). A technician services the element, but the base remains fixed to the truck. This modularity is a core part of the Топливный фильтр тонкой очистки FAW дизайн.

The name “Топливный тонкий фильтр” is not a marketing term; it is a critical engineering specification. Этот Топливный фильтр тонкой очистки FAW is the final, and most important, stage of filtration before the fuel enters the High-Pressure Common Rail (HPCR) injection system. This system’s components, particularly the injectors, are built to tolerances of less than 3-5 microns (a human hair is about 70 microns).

**1. Abrasive Particle Removal:** The primary job of the Топливный фильтр тонкой очистки FAW media is to trap microscopic hard particles. This includes silica (fine dirt) that may get past the primary filter, and rust or metal flakes from fuel tanks and stations. If even one of these particles reaches the injector, it acts like a sandblaster, eroding the injector’s delicate pintle and nozzle seat. This erosion causes the injector to leak, resulting in poor fuel atomization, black smoke, high fuel consumption, and eventual engine failure.

**2. Water Coalescing (Separation):** The secondary, and equally critical, function of the Топливный фильтр тонкой очистки FAW is water separation. Diesel fuel naturally absorbs and carries water. This water is catastrophic for an HPCR system. First, it causes rust and corrosion on the precision-machined internal surfaces of the pump and injectors. Second, when water (which is incompressible) is subjected to 30,000+ PSI, it can instantly blow the tip off an injector. The advanced media in the Топливный фильтр тонкой очистки FAW является “hydrophobic.” It repels water, forcing the tiny emulsified water droplets to “coalesce” (merge) into larger, heavier droplets, which then fall out of the fuel flow and are collected in a bowl at the bottom of the filter assembly, where they can be drained.

Using a non-genuine filter element can destroy this engine. A cheap filter that cannot meet the “fine” micron rating or cannot properly coalesce water will allow these contaminants to pass, leading to thousands of dollars in repairs to the fuel injection system. The entire Топливный фильтр тонкой очистки FAW сборка (1117010-81Д) is the gatekeeper that protects the engine’s most expensive components. This makes the Топливный фильтр тонкой очистки FAW one of the most important serviceable parts on the entire truck.

The ‘Fuel Fine Filter Bracket Assembly’ (1117120-81Д) is the structural foundation for the entire system. This is a heavy-duty, stamped steel bracket designed to be bolted directly to the truck’s main chassis frame rail.

Its function is two-fold. First, it provides a stable, rigid mounting location for the ‘Fuel Fine Filter Base Assembly’ (1117020-81Д). This is crucial for preventing the heavy, fuel-filled filter assembly from vibrating. Second, it isolates the Топливный фильтр тонкой очистки FAW system from the high-frequency vibrations of the engine. By mounting the filter on the “sprung” chassis instead of the “unsprung” двигатель, the fuel lines and fittings are subjected to far less stress, preventing fatigue, cracks, and dangerous high-pressure fuel leaks.

The parts list details a specific set of high-tensile fasteners to secure the Топливный фильтр тонкой очистки FAW system. This hardware is not optional; it is engineered for this specific application.

**Bracket-to-Chassis Fasteners:** The ‘Hex flange bolts’ (Q1841075 and Q1841020), with two of each, are the main bolts that secure the ‘Bracket Assembly’ (1117120-81Д) to the truck’s frame rail. The different part numbers indicate different lengths, required for the specific geometry of the chassis mount. The flange head is critical for spreading the load and resisting loosening from road vibration.

**Base-to-Bracket Fasteners:** The two ‘Hex flange bolts’ (Q1841030) and two ‘Hex nuts’ (CQ34010) are the hardware used to secure the ‘Fuel Fine Filter Base Assembly’ (1117020-81Д) *to* the ‘Bracket Assembly’. This bolt-and-nut combination allows the base to be securely “sandwiched” onto the bracket, creating the final, rigid Топливный фильтр тонкой очистки FAW сборка.

The following table provides the complete, detailed breakdown of all components identified in the ‘Fuel Fine Filter’ diagram for the FAW CA4251P66K24T1A3E5 tractor. Servicing the Топливный фильтр тонкой очистки FAW (1117050-81Д) is a critical maintenance task.

| Mark | Часть №. | Наименование | Количество |

|---|---|---|---|

| 1 | 1117010-81Д | Fuel Fine Filter Assembly (as-per-sample) | 1 |

| 1117020-81Д | Fuel Fine Filter Base Assembly | 1 | |

| 1117050-81Д | Fuel Fine Filter Element Assembly (as-per-sample) | 1 | |

| 2 | 1117120-81Д | Fuel Fine Filter Bracket Assembly | 1 |

| 3 | Q1841030 | Hex flange bolt, coarse rod (Стандартный тип) | 2 |

| 4 | CQ34010 | Шестнадцатеричный орех | 2 |

| 5 | Q1841075 | Hex flange bolt, coarse rod (Стандартный тип) | 2 |

| 6 | Q1841020 | Hex flange bolt, coarse rod (Стандартный тип) | 2 |

The specifications for the Топливный фильтр тонкой очистки FAW are defined by its function as the final protection for the High-Pressure Common Rail (HPCR) injection system. The entire Топливный фильтр тонкой очистки FAW assembly is a critical component.

| Vehicle Application | FAW Jiefang CA4251P66K24T1A3E5 6×4 Tractor |

| Component Group | Топливный фильтр тонкой очистки FAW |

| Complete Assembly P/N | 1117010-81Д |

| Permanent Base P/N | 1117020-81Д (Filter Head / Base) |

| Serviceable Element P/N | 1117050-81Д (Spin-on Cartridge) |

| Mounting System | Chassis-Mounted Bracket (1117120-81Д) |

| Primary Function | Micro-particle filtration (Abrasive removal) |

| Secondary Function | Water separation (Coalescing) |

| Protected System | High-Pressure Common Rail (HPCR) Pump and Injectors |

FAW parts, including the Cylinder Block Assembly, are packaged with care to ensure safe delivery. Each component is secured in protective materials to prevent damage during transit. The logistics network guarantees timely shipments worldwide, supporting efficient maintenance operations. Below is an image illustrating the standard packaging for FAW truck parts, showcasing the attention to detail in handling and storage.

This packaging approach minimizes the risk of corrosion or impact damage, ensuring that parts like the FAW Cylinder Block Assembly arrive in perfect condition. Customers can rely on FAW’s logistics for consistent quality and reliability.