Welcome to this critical technical analysis of the FAW Front Lateral Stabiliser Bar And Boom Logic Assembly (Часть №. 2906010-1063). This is the complete “anti-roll” или “sway bar” system for the front axle of the FAW Jiefang CA4251P66K24T1A3E5 6×4 diesel semi-trailer tractor. This assembly is a critical safety component for vehicle stability.

The “logic” of the FAW Front Lateral Stabiliser Bar And Boom Logic Assembly is to counteract the natural “body roll” of a high-center-of-gravity vehicle during cornering. It functions as a torsional spring, connecting the left and right sides of the suspension to keep the truck’s cab and frame level, ensuring maximum tire contact and steering control.

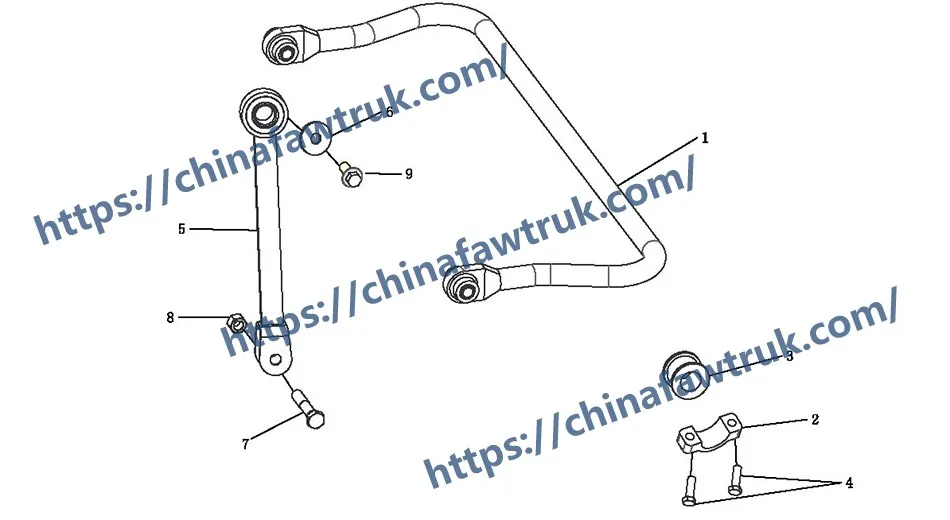

This in-depth guide is an essential resource for professional suspension technicians and fleet managers. We will deconstruct the entire FAW Front Lateral Stabiliser Bar And Boom Logic Assembly into its 9 serviceable component types, including the main ‘Stabiliser bar’, the ‘Boom & bushing assembly’ (end links), the chassis brackets, and all critical mounting hardware.

The heart of the FAW Front Lateral Stabiliser Bar And Boom Logic Assembly is the ‘Front lateral stabiliser bar assy’ (2906010-1063). This is the “bar” сам, a single, U-shaped component forged from high-carbon, heat-treated spring steel.

This component’s “logic” is that of a **torsional spring**. It is designed to twist. The main body of the bar is mounted to the truck’s rigid chassis frame, where it is held by the ‘Bushing-lateral stabiliser bar’ (2906447-50А). The two “arms” of the bar extend outwards and connect to the moving axle via the ‘Boom & bushing assy’ (2906320-92В).

When the truck corners, the chassis “rolls” (leans) to the outside. This forces the outside suspension to compress (move up) and the inside suspension to “droop” (move down). As the outside axle moves up, it pushes its “boom” up, twisting the stabilizer bar. The bar’s spring-steel construction resists this twist. This resistance force is then transferred along the bar to the *other* side, where it *pulls up* on the *inside* “boom,” effectively lifting the inside axle and counteracting the body roll.

This action keeps the cab and frame significantly flatter, maintaining proper suspension geometry and ensuring both front tires remain in firm contact with the road for maximum steering and braking grip. A broken or fatigued FAW Front Lateral Stabiliser Bar And Boom Logic Assembly will result in dangerous, excessive body roll and unresponsive, “wallowing” handling.

The “Boom” component of the FAW Front Lateral Stabiliser Bar And Boom Logic Assembly is the ‘Boom & bushing assy-front lateral stabiliser bar’ (2906320-92В). The parts list calls for two of these, one for each side. This is commonly known as the “stabilizer end link” или “drop link.”

This is the vertical linkage that connects the horizontal stabilizer bar to the moving front axle. It is a heavy-duty steel rod or forging. The “bushing assy” designation is critical, as it indicates this component comes with pre-installed, high-durometer rubber bushings at both ends.

These bushings are essential. They act as small, high-stiffness pivot points. They must be stiff enough to instantly transfer the suspension’s movement to the bar, but flexible enough to absorb high-frequency road vibrations and prevent the harshness from being transmitted into the chassis.

The bushings on this FAW Front Lateral Stabiliser Bar And Boom Logic Assembly component are a primary wear item. Через некоторое время, they will crack, stiffen, или “oval” from the constant stress. A worn bushing is the most common cause of a “clunking” или “rattling” sound from the front end when driving over small, sharp bumps. Replacing these “booms” is a common maintenance task to restore the silent, tight operation of the MSF_FAW Front Lateral Stabiliser Bar And Boom Logic Assembly.

The main ‘Stabiliser bar’ (2906010-1063) must be rigidly attached to the truck’s chassis frame, but in a way that still allows it to rotate (twist). This is the “logic” of the chassis mounting system within the FAW Front Lateral Stabiliser Bar And Boom Logic Assembly.

This is achieved by the ‘Bushing-lateral stabiliser bar’ (2906447-50А). The list calls for two of these. They are large, “D-shaped” rubber bushings that are split on one side. They are clamped around the main bar. This tough rubber holds the bar in its precise location and dampens vibration, while its greased inner bore allows the bar to pivot freely.

These bushings are held in place by the ‘Cover-front lateral stabiliser bar bracket’ (2906446-50А). These two heavy-duty steel “caps” are bolted to the main chassis frame using the four ‘Hex head bolts’ (CQ1511445), clamping the bushings and the bar firmly against the frame. Worn bushings here will cause a “clunk” and allow the entire FAW Front Lateral Stabiliser Bar And Boom Logic Assembly к “walk” side-to-side, reducing its effectiveness.

The rest of the FAW Front Lateral Stabiliser Bar And Boom Logic Assembly consists of the high-tensile hardware that secures the “Booms” (end links).

The ‘Hex head bolt’ (CQ15120100) and ‘Hex nut’ (CQ34120) are the large, high-strength fasteners (two of each) that secure the “Booms” to the axle or frame.

The ‘Inner washer-lateral stabiliser bar boom anti-loosening bolt’ (2906412-50А) является критическим компонентом. This is not a simple washer. It is an “anti-loosening” Шайтика, likely a “tab-lock” washer or a “serrated” (Nord-Lock style) Шайтика. Its “logic” is to create a mechanical lock that prevents the main pivot nut (CQ34120) from backing off under the constant, twisting load of the FAW Front Lateral Stabiliser Bar And Boom Logic Assembly.

Окончательно, the ‘Hex head flange bolt’ (Q1851845T) units are high-strength flange bolts used to secure the ‘Cover’ (2906446-50А) to the chassis. This complete, robust hardware set ensures the FAW Front Lateral Stabiliser Bar And Boom Logic Assembly remains tight, quiet, and effective.

The following table provides the complete, detailed breakdown of all 9 components identified in the ‘Front Lateral Stabiliser Bar And Boom Logic Assembly’ (506) diagram for the FAW CA4251P66K24T1A3E5 tractor.

| Mark | Часть №. | Наименование | Количество |

|---|---|---|---|

| 1 | 2906010-1063 | Front lateral stabiliser bar assy | 1 |

| 2 | 2906446-50А | Cover-front lateral stabiliser bar bracket | 2 |

| 3 | 2906447-50А | Bushing-lateral stabiliser bar | 2 |

| 4 | CQ1511445 | Hex head bolt | 4 |

| 5 | 2906320-92В | Boom & bushing assy-front lateral stabiliser bar | 2 |

| 6 | 2906412-50А | Inner washer-lateral stabiliser bar boom anti-loosening bolt | 2 |

| 7 | CQ15120100 | Hex head bolt | 2 |

| 8 | CQ34120 | Шестнадцатеричный орех | 2 |

| 9 | Q1851845T | Hex head flange bolt | 2 |

The specifications for the FAW Front Lateral Stabiliser Bar And Boom Logic Assembly are defined by its function as a torsional spring system to control body roll. The FAW Front Lateral Stabiliser Bar And Boom Logic Assembly is a key component for vehicle stability.

| Vehicle Application | FAW Jiefang CA4251P66K24T1A3E5 6×4 Tractor |

| Component Group | FAW Front Lateral Stabiliser Bar And Boom Logic Assembly |

| Common Name | Anti-Roll Bar / Sway Bar Assembly |

| Main Bar P/N | 1x (Часть №. 2906010-1063) |

| End Links (“Boom”) Артикул | 2x (Часть №. 2906320-92В) |

| Chassis Mounts | 2x Covers (2906446-50А) & 2x Bushings (2906447-50А) |

| “Boom” Hardware | 2x Bolts (CQ15120100), 2x Nuts (CQ34120), 2x Washers (2906412-50А) |

| Chassis Mount Hardware | 4x Bolts (CQ1511445), 2x Flange Bolts (Q1851845T) |

| Primary Function | To resist torsional force (twisting) during cornering, keeping the vehicle level and maximizing tire grip. |

FAW parts, including the Cylinder Block Assembly, are packaged with care to ensure safe delivery. Each component is secured in protective materials to prevent damage during transit. The logistics network guarantees timely shipments worldwide, supporting efficient maintenance operations. Below is an image illustrating the standard packaging for FAW truck parts, showcasing the attention to detail in handling and storage.

This packaging approach minimizes the risk of corrosion or impact damage, ensuring that parts like the FAW Cylinder Block Assembly arrive in perfect condition. Customers can rely on FAW’s logistics for consistent quality and reliability.