Welcome to this comprehensive technical guide on the FAW First Shaft Assembly And Input Gear, the complete “input” group for the manual transmission in the FAW Jiefang CA4251P66K24T1A3E5 6×4 diesel semi-trailer tractor. This assembly is the critical link between the engine’s clutch and the transmission’s gearset.

The FAW First Shaft Assembly And Input Gear (also known as the input shaft) is responsible for receiving 100% of the engine’s torque from the clutch disc. It holds the main ‘Input Gear’ (1701121-A0L) который, по очереди, drives the transmission’s counter-shaft, setting the entire gear-driven system in motion.

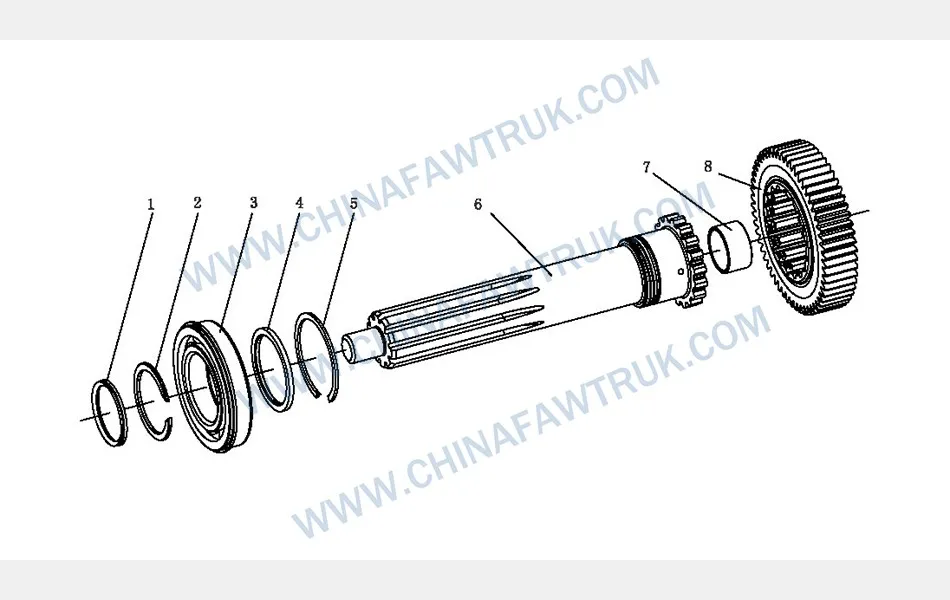

This in-depth guide is an essential resource for professional transmission technicians and parts specialists. We will deconstruct the entire FAW First Shaft Assembly And Input Gear, breaking it down into its 11 serviceable components, including the main shaft, the input gear, the critical support bearings, and all the circlips and seals that ensure its precise alignment and leak-free operation.

The FAW First Shaft Assembly And Input Gear is composed of two primary, named components:

**1. First Shaft – Передача инфекции (1701112-A7G):** This is the “First Shaft,” more commonly known as the transmission input shaft. It is a high-strength, hardened steel shaft. The front “nose” of this shaft is splined and extends into the clutch housing, where it engages with the splined hub of the clutch disc. This spline is what allows the FAW First Shaft Assembly And Input Gear to be connected (and disconnected) from the engine’s flywheel.

**2. Input Gear – First Shaft (1701121-A0L):** This is the “Input Gear.” This large, helically-cut gear is permanently fixed (either splined or press-fit) onto the ‘First Shaft’. Its function is to transfer 100% of the engine’s torque from the shaft to the transmission’s counter-shaft, which is in constant mesh with this gear. The helical cut of the teeth is a critical design feature, ensuring quiet operation and maximum surface area contact for high-torque transfer. A chipped or worn tooth on this gear is a catastrophic failure for the FAW First Shaft Assembly And Input Gear and the entire transmission.

The entire FAW First Shaft Assembly And Input Gear must be supported as it spins under immense loads. This is the job of the ‘Deep groove ball bearing with stop ring’ (6212-ZNBR/C3YB2). This is the main bearing for the input shaft.

This large, heavy-duty ball bearing (а “6212” ряд) is pressed onto the ‘First Shaft’ (1701112-A7G). Its outer race is then secured in a precision-bored hole in the ‘Front housing’ (bell housing) of the transmission case. This bearing must handle both the “radial” нагрузка (the sideways force from the gears pushing against each other) and the “axial” нагрузка (the push/pull force from the clutch being engaged and disengaged).

The “stop ring” (or snap ring) on the bearing’s outer race is a critical feature. This ring fits into a groove in the transmission housing, locking the bearing (and thus the entire FAW First Shaft Assembly And Input Gear) in its precise fore-and-aft position. This is a vital function for maintaining the perfect gear mesh inside the transmission.

The FAW First Shaft Assembly And Input Gear requires incredibly precise “end-play” (the amount of in-and-out movement). This is controlled by a complex set of “selective fit” circlips and a gasket.

The parts list calls out four separate ‘Circlip – Первый вал задний подшипник’ items (1701131-A7G, 1701132-A7G, 1701133-A7G, and 1701134-A7G), as well as a ‘Gasket – Первый вал задний подшипник’ (1701123-A7G). This indicates that these parts are not identical.

This is a “selective fit” или “shimming” system. The different part numbers for the circlips correspond to different, precise thicknesses. During assembly, a technician must measure the shaft’s end-play with a dial indicator. They will then consult a chart and select the correct-thickness circlip and/or gasket from this set. This process “sets the preload” on the main bearing. Using the wrong circlip will cause the FAW First Shaft Assembly And Input Gear to be too “tight” (leading to bearing failure) or too “loose” (leading to gear whine and misalignment).

A separate ‘Circlip – задняя передача’ (1701314-A7G) is also listed. This is a standard snap ring used to hold the reverse idler gear in its proper place on its own shaft, which is also part of the FAW First Shaft Assembly And Input Gear‘s overall function.

The FAW First Shaft Assembly And Input Gear is completed by two critical, but small, компоненты: the ‘Bushing’ (1701111-A7G) and the ‘Oil seal – первый вал’ (1701135-A7G).

**1. The ‘Oil seal’ (1701135-A7G):** This is the main “input shaft seal.” It is a radial lip seal that is pressed into the front of the transmission housing. Its flexible rubber lip rides on a polished surface of the first shaft. Its only job is to keep the transmission’s gear oil *inside* the transmission. A failure of this seal is a critical failure of the FAW First Shaft Assembly And Input Gear system, as it allows gear oil to leak into the dry clutch housing, saturating the clutch disc and causing it to slip and fail.

**2. The ‘Bushing’ (1701111-A7G):** This is the “pilot bushing” for the main shaft. The rear of the ‘First Shaft’ (input shaft) is hollowed out. The “nose” или “tip” of the transmission’s *main* shaft (the one with all the sliding gears) fits *inside* this hollowed-out section. This bushing, made of bronze or a similar low-friction material, is pressed into this hole. It provides the front support for the entire main shaft. A worn bushing here will cause the main shaft to “wobble,” leading to gear grinding, вибрация, and shifting problems. It is a critical, often-overlooked part of the FAW First Shaft Assembly And Input Gear.

The following table provides the complete, detailed breakdown of all 11 components identified in the ‘First Shaft Assembly and Input Gear’ diagram for the FAW CA4251P66K24T1A3E5 tractor. A rebuild of the FAW First Shaft Assembly And Input Gear requires careful selection of the correct circlips.

| Mark | Часть №. | Наименование | Количество |

|---|---|---|---|

| 1 | 1701135-A7G | Oil seal – первый вал | 1 |

| 2 | 1701131-A7G | Circlip – Первый вал задний подшипник | 1 |

| 3 | 1701132-A7G | Circlip – Первый вал задний подшипник (See 1701131-A7G) | 1 |

| 4 | 1701133-A7G | Circlip – Первый вал задний подшипник (See 1701131-A7G) | 1 |

| 5 | 1701134-A7G | Circlip – Первый вал задний подшипник (See 1701131-A7G) | 1 |

| 6 | 6212-ZNBR/C3YB2 | Deep groove ball bearing with stop ring | 1 |

| 7 | 1701123-A7G | Прокладка – Первый вал задний подшипник | 1 |

| 8 | 1701314-A7G | Circlip – задняя передача | 1 |

| 9 | 1701112-A7G | First shaft – transmission | 1 |

| 10 | 1701111-A7G | Втулка | 1 |

| 11 | 1701121-A0L | Input gear – первый вал | 1 |

The specifications for the FAW First Shaft Assembly And Input Gear are defined by its function as the primary torque input for the transmission. Этот FAW First Shaft Assembly And Input Gear is a precision-balanced, high-strength assembly.

| Vehicle Application | FAW Jiefang CA4251P66K24T1A3E5 6×4 Tractor |

| Component Group | FAW First Shaft Assembly And Input Gear |

| Main Shaft P/N | 1701112-A7G (Input Shaft) |

| Main Gear P/N | 1701121-A0L (Input Gear) |

| Main Bearing P/N | 6212-ZNBR/C3YB2 (Радиальный шарикоподшипник) |

| Main Seal P/N | 1701135-A7G (Oil Seal) |

| Pilot Bushing P/N | 1701111-A7G |

| End-Play Control | Selective-fit Circlips (1701131/2/3/4-A7G) |

| Primary Function | To transmit 100% of engine torque from the clutch disc to the transmission’s counter-shaft. |

FAW parts, including the Cylinder Block Assembly, are packaged with care to ensure safe delivery. Each component is secured in protective materials to prevent damage during transit. The logistics network guarantees timely shipments worldwide, supporting efficient maintenance operations. Below is an image illustrating the standard packaging for FAW truck parts, showcasing the attention to detail in handling and storage.

This packaging approach minimizes the risk of corrosion or impact damage, ensuring that parts like the FAW Cylinder Block Assembly arrive in perfect condition. Customers can rely on FAW’s logistics for consistent quality and reliability.