Welcome to the complete technical guide for the FAW Cylinder Head Cover And Oil Filler Cap sistema, a crucial set of components for the FAW Jiefang CA4251P66K24T1A3E5 6×4 diesel semi-trailer tractor. This assembly is the first line of defense for the engine’s valvetrain.

This system, o FAW Cylinder Head Cover And Oil Filler Cap, serves multiple critical functions: it seals the top of the engine, protecting the delicate camshafts and valve gear from dirt and moisture. It also contains the engine oil that lubricates these components, preventing leaks. Além disso, it houses the engine’s crankcase ventilation system and provides the service point for adding engine oil.

This guide is designed for professional technicians and parts managers, providing a detailed breakdown of the entire FAW Cylinder Head Cover And Oil Filler Cap conjunto. We will deconstruct the system into its smallest serviceable units, from the main cover and its gasket to the specialized bolts and the oil cap assembly, ensuring every service is performed accurately.

The largest component in this assembly is the ‘Cylinder Head Cover’ (1003031-81D). On modern diesel engines, this part is a highly engineered component, often made from a high-strength, glass-filled composite (plastic) or a lightweight cast aluminum. A composite design is often preferred as it reduces engine-top weight and is significantly quieter, damping the “ticking” sound of the valvetrain.

This component’s primary function is to act as a static seal, but its secondary function is just as critical. This cover contains the engine’s Positive Crankcase Ventilation (PCV) sistema. As the engine runs, some combustion gases (“blow-by”) inevitably push past the piston rings and into the crankcase. This builds pressure and must be ventilated.

No entanto, these gases are mixed with a fine mist of hot engine oil. O FAW Cylinder Head Cover And Oil Filler Cap assembly is designed with a complex series of internal channels, baffles, and oil-air separators. As the crankcase gases flow into the cover, they are forced through this “labyrinth.” The heavier liquid oil droplets collide with the baffle walls, condense, and drain back into the cylinder head, returning to the oil sump.

The remaining oil *vapor* (along with the blow-by gases) is then drawn out of a port on the cover and routed into the engine’s air intake, just before the turbocharger. This allows the unburnt hydrocarbons to be re-burned, which is a critical emissions control function. If this internal baffle system becomes clogged or fails, the engine will draw liquid oil into the intake, leading to high oil consumption, blue smoke from the exhaust, and the fouling of the turbocharger and intercooler.

The ‘Cylinder Head Cover’ itself is a static part; the ‘Cylinder Head Cover Gasket’ (1003041-81D) is the active component that makes the seal. This is the single most common failure point in the FAW Cylinder Head Cover And Oil Filler Cap sistema.

This is not a simple paper gasket. It is a “profile” gasket, precision-molded from an advanced, oil-resistant elastomer (like silicone or FKM/Viton). It is designed to sit perfectly within a groove that runs along the entire perimeter of the plastic or aluminum cover. It also includes integrated O-rings that loop around the bolt holes and the spark plug tubes (if applicable), creating a complete, one-piece sealing solution.

This gasket lives in a brutal environment, subjected to constant engine vibration, heat cycles (from ambient temperature to over 100°C and back), and continuous exposure to hot engine oil. Over many thousands of hours, this elastomer will harden, become brittle, and compress. When this happens, it loses its sealing ability, and oil begins to weep.

A leaking head cover gasket is a common maintenance item. The diagnosis is simple: visual signs of “sweating” or active oil drips from the seam between the head and the cover. Often, this oil will drip onto the hot exhaust manifold, creating a distinct burning oil smell. Replacing this gasket is a standard service procedure, but it must be done correctly by following the precise bolt-tightening sequence to avoid damaging the new gasket.

The gasket’s seal is only as good as the clamping force applied to it. This is the job of the 17 ‘Cylinder Head Cover Bolt Assembly’ unidades (1003060-81D). The high quantity of 17 bolts is necessary to distribute the clamping pressure evenly across the long, complex perimeter of the gasket, ensuring there are no “loose spots” where oil could escape.

These are designated as a “bolt assembly” because they are not just simple bolts. Each one almost certainly includes a captive metal washer and, most importantly, a rubber isolator or “grommet.” This grommet is a critical part of the FAW Cylinder Head Cover And Oil Filler Cap design.

This rubber grommet serves two functions. First, it seals the bolt hole, preventing oil from leaking up the bolt threads and pooling on top of the cover. Second, it acts as a “soft torque” stop. When installing a composite cover, over-tightening is a major risk; it can crack the cover or “split” the gasket. These bolts are not designed to be tightened with high force. The technician tightens them until the metal washer compresses the rubber grommet. This provides a “built-in” torque limit and isolates the cover from engine vibration, preventing the bolts from backing out.

The final two components form the primary user interaction point of the FAW Cylinder Head Cover And Oil Filler Cap sistema. The ‘Oil Filler Cap’ (1003037-29D) is the removable, twist-lock cap that allows a technician or operator to add engine oil.

The functional part, however, is the ‘Seal Ring-Oil Filler Cap’ (1003036-29D). This is a simple O-ring or flat rubber gasket that sits in a groove on the cap. Its function is far more important than just preventing oil from “splashing” out. This seal is a critical part of the crankcase ventilation system.

The PCV system, described earlier, is designed to maintain a slight *vacuum* inside the engine’s crankcase. If this cap seal is missing, cracked, or hardened, it creates a “vacuum leak.” This allows un-metered, *unfiltered* air to be sucked directly into the engine’s valvetrain. This dirty air contaminates the engine oil and bypasses the PCV’s oil-separating baffles.

A failed cap seal can disrupt the delicate balance of the PCV, potentially leading to incorrect pressure in the crankcase. In a worst-case scenario, if the PCV system gets clogged, a failed cap seal can become an *outlet* for crankcase pressure, pushing oily fumes out and making a mess of the engine bay. This small, inexpensive ‘Seal Ring’ is a critical component for maintaining the health of the entire engine and the proper function of the FAW Cylinder Head Cover And Oil Filler Cap.

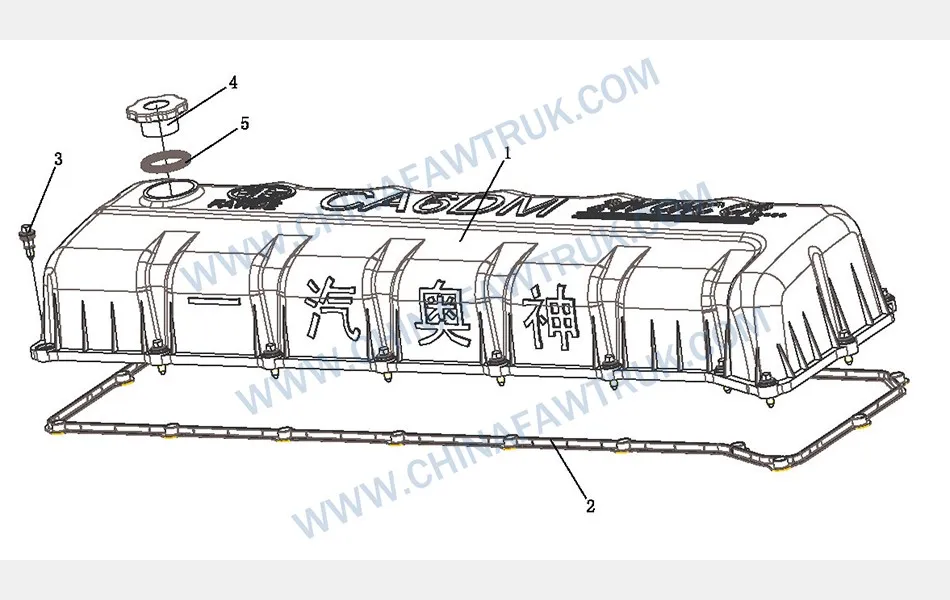

The following table provides the complete, detailed breakdown of all components identified in the ‘Cylinder Head Cover and Oil Filler Cap’ diagram for the FAW CA4251P66K24T1A3E5 tractor.

| Mark | Parte não. | Nome da peça | Quantidade |

|---|---|---|---|

| 1 | 1003031-81D | Tampa da cabeça do cilindro | 1 |

| 2 | 1003041-81D | Cylinder Head Cover Gasket | 1 |

| 3 | 1003060-81D | Cylinder Head Cover Bolt Assembly | 17 |

| 4 | 1003037-29D | Tampa de preenchimento de óleo | 1 |

| 5 | 1003036-29D | Seal Ring-Oil Filler Cap | 1 |

The specifications for the FAW Cylinder Head Cover And Oil Filler Cap are centered on its role as the primary sealing and ventilation system for the engine’s valvetrain.

| Vehicle Application | FAW Jiefang CA4251P66K24T1A3E5 6×4 Tractor |

| Component Group | Cylinder Head Cover And Oil Filler Cap |

| Main Cover Part No. | 1003031-81D |

| Main Gasket Part No. | 1003041-81D (Profile Elastomer Gasket) |

| Fastener System | 17x Bolt Assemblies (1003060-81D) with Isolators |

| Oil Service Cap Part No. | 1003037-29D |

| Oil Cap Seal Part No. | 1003036-29D (Anel-O / Anel de vedação) |

| Primary Function | Seals valvetrain, contains oil, integrates PCV system, provides oil filler access. |

FAW parts, including the Cylinder Block Assembly, are packaged with care to ensure safe delivery. Each component is secured in protective materials to prevent damage during transit. The logistics network guarantees timely shipments worldwide, supporting efficient maintenance operations. Below is an image illustrating the standard packaging for FAW truck parts, showcasing the attention to detail in handling and storage.

This packaging approach minimizes the risk of corrosion or impact damage, ensuring that parts like the FAW Cylinder Block Assembly arrive in perfect condition. Customers can rely on FAW’s logistics for consistent quality and reliability.