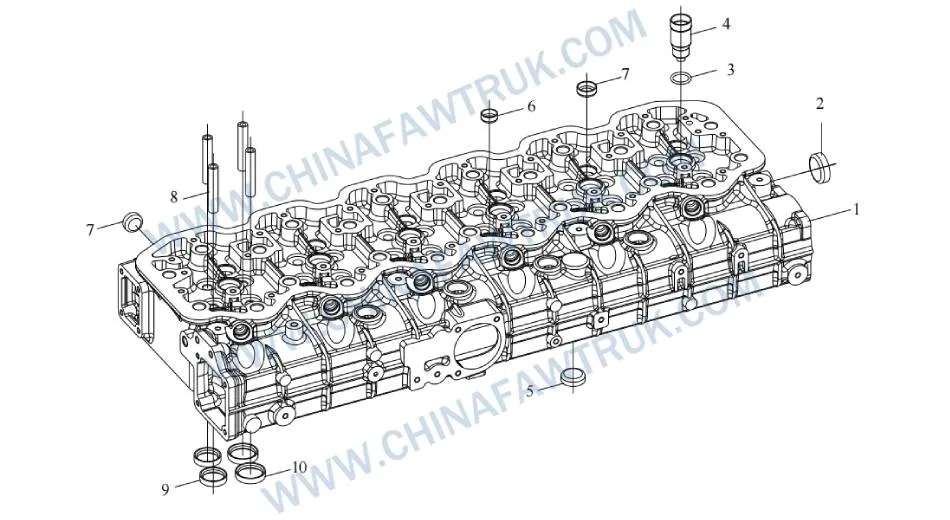

The FAW Cylinder Head represents a critical component in the high-performance CA3250P66K2L1T1E 6×4 dump truck engine manufactured by FAW Jiefang. This comprehensive exploded view guide provides an intricate breakdown of the cylinder head assembly, systematically disassembling the main casting and integrated components down to the smallest serviceable repair units. Our detailed analysis covers both versions – with and without engine brake compatibility – enabling maintenance technicians to identify, service, and replace individual components with precision. Understanding the complete FAW Cylinder Head architecture is essential for optimal combustion efficiency, valve timing accuracy, and overall engine performance in demanding heavy-duty applications.

Disassembling the FAW Cylinder Head requires a systematic approach that begins with removing external components and progresses to internal valve train elements. The process involves carefully separating the main casting from its integrated components, ensuring each part can be individually inspected, serviced, or replaced. Key disassembly stages include removing valve covers, rocker arms, inyectores, and eventually accessing the valve seats and guides.

The FAW Cylinder Head design incorporates both standard and engine brake compatible versions, each requiring specific attention during disassembly. The modular construction allows for efficient breakdown without compromising the integrity of the main casting. This approach significantly reduces repair time and costs by enabling targeted component replacement rather than complete assembly replacement.

Proper disassembly of the FAW Cylinder Head ensures that critical components like valve seats, guides, and injector sleeves can be thoroughly inspected for wear or damage. Following the exploded view diagram precisely and referring to the detailed parts list guarantees accurate identification and proper handling of each component throughout the maintenance process.

This comprehensive parts list for the FAW Cylinder Head details every component visible in the exploded view diagram. Each part is identified by its official part number, description, and quantity required for the complete assembly. This reference enables accurate identification, ordering, and replacement of individual components during maintenance procedures.

| Reference | Part Number | Nombre de la pieza | Cantidad |

|---|---|---|---|

| 1 | 1003011A59D (1003011-630-000z) |

Cylinder Head (with engine brake) | 1 |

| 1 | 1003011-59D (1003011B630-000Z) |

Cylinder Head (without engine brake) | 1 |

| 2 | Q72240 | Bowl Shape Plug | 1 |

| 3 | 1003018-29D (1003018C29D) |

junta tórica | 6 |

| 4 | 1003016-29D (1003016A29D) |

Fuel Injector Steel Sleeve | 6 |

| 5 | Q72232 | Bowl Shape Plug (with engine brake) | 1 |

| 6 | Q72222 | Bowl Shape Plug | 6 |

| 7 | Q7226 | Bowl Shape Plug | 16 |

| 8 | 1003014-29D (1003014M29D) |

Valve Guide | 24 |

| 9 | 1003013-36D | Asiento de válvula de escape | 12 |

| 10 | 1003012-36D | Asiento de válvula de admisión | 12 |

This detailed FAW Cylinder Head parts list serves as an essential reference for maintenance operations. Each component is engineered to precise specifications, ensuring reliable performance under the demanding conditions typical of heavy-duty dump truck applications. When ordering replacement parts, always verify part numbers against this official list to guarantee compatibility and optimal performance of your FAW Cylinder Head assembly.

The FAW Cylinder Head for the CA3250P66K2L1T1E model incorporates advanced engineering features designed specifically for heavy-duty applications. The following technical parameters provide essential information for proper installation, mantenimiento, and compatibility verification. These specifications ensure the FAW Cylinder Head meets the rigorous demands of construction and mining operations where reliability is paramount.

| Parámetro | Especificación |

|---|---|

| Modelo de vehículo | CA3250P66K2L1T1E |

| Engine Configuration | 6-Cylinder In-Line Diesel |

| Head Material | High-Strength Cast Iron Alloy |

| Valve Configuration | 4 Valves per Cylinder |

| Total Valves | 24 |

| Injector Sleeves | 6 (One per Cylinder) |

| Combustion Chamber Design | Direct Injection Optimized |

| Cooling Passage Design | Cross-Flow Cooling |

| Peso | Approximately 85 kg |

| Engine Brake Compatibility | Available in Two Versions |

| Valve Seat Material | Heat-Resistant Steel Alloy |

| Valve Guide Material | Bronze Alloy |

These technical specifications demonstrate the robust construction and engineering excellence of the FAW Cylinder Head. Designed to withstand extreme operating conditions and high combustion pressures, the FAW Cylinder Head ensures reliable performance throughout its service life. Regular maintenance according to these parameters will maximize durability and minimize downtime for your FAW truck operations.

Proper maintenance of the FAW Cylinder Head is crucial for ensuring optimal engine performance and longevity in your CA3250P66K2L1T1E dump truck. Begin with regular visual inspections checking for cracks, warpage, or surface damage, particularly around combustion chambers, valve seats, and injector sleeves. Use the exploded view diagram as a reference during disassembly to ensure proper component identification and handling.

When servicing the FAW Cylinder Head, pay special attention to valve guides and seats, which require precise installation and proper sealing. El 24 valve guides must be properly seated to ensure optimal valve alignment and minimal wear. Similarmente, intake and exhaust valve seats should be inspected for proper sealing and replaced if any signs of burning or pitting are detected.

Regular inspection and replacement of sealing components like O-rings and bowl shape plugs is essential for preventing coolant and compression leaks in the FAW Cylinder Head assembly. Fuel injector steel sleeves must be carefully installed to ensure proper fuel spray patterns and prevent combustion gas leakage. Always use genuine FAW replacement parts and follow manufacturer torque specifications during reassembly to maintain the structural integrity and performance of your FAW Cylinder Head.

The FAW Cylinder Head offers numerous advantages that contribute to the overall performance and efficiency of FAW trucks. Its robust construction using high-strength cast iron alloy provides exceptional resistance to thermal stress and mechanical loads, ensuring reliable operation in the most demanding conditions. The four-valve per cylinder design optimizes airflow for improved combustion efficiency and power output.

Precision-engineered components within the FAW Cylinder Head assembly, such as the bronze alloy valve guides and heat-resistant steel valve seats, ensure optimal valve operation and extended service life under high-temperature conditions. This precision engineering translates to improved fuel efficiency, emisiones reducidas, and consistent performance across the engine’s operational range.

The availability of both standard and engine brake compatible versions of the FAW Cylinder Head provides flexibility for different operational requirements. The comprehensive parts availability and detailed documentation further enhance the maintainability of the FAW Cylinder Head, making it an excellent choice for fleet operators seeking reliability, actuación, and cost-effective operation in heavy-duty applications.