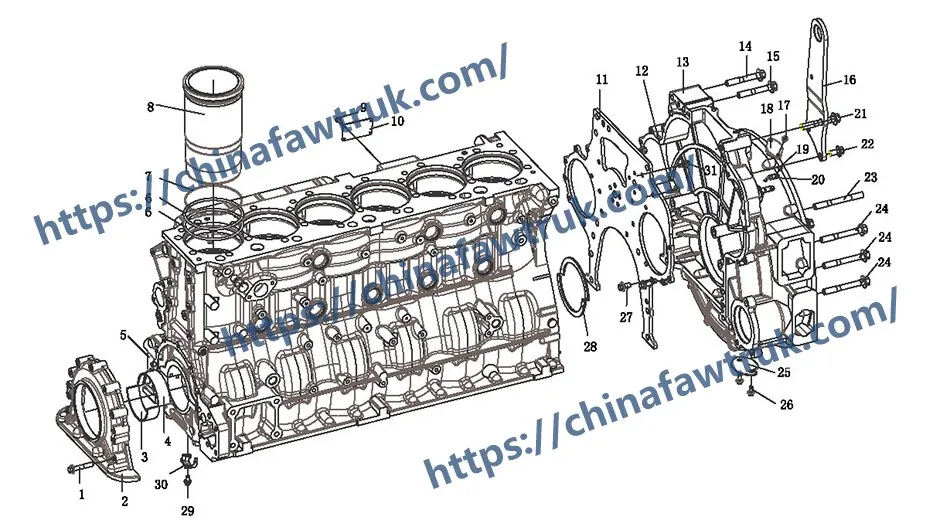

Welcome to this in-depth technical guide for the FAW Cylinder block assembly, the foundational power component for the FAW Jiefang CA4251P66K24T1A3E5 6×4 diesel semi-trailer tractor. This document provides an essential, detailed analysis of the complete assembly and its associated parts.

This exploded view analysis is designed to deconstruct the entire FAW Cylinder block assembly, from its major structural castings and procured components down to the smallest serviceable units. We identify every bolt, seal, несущий, and plug, providing the clarity needed for complex service operations.

For technicians, engine rebuild specialists, and fleet parts managers, this guide is an indispensable resource. A precise understanding of the FAW Cylinder block assembly is critical for accurate parts ordering, efficient maintenance, and ensuring the long-term reliability and peak performance of the engine.

At the heart of the entire powertrain is the ‘Cylinder Block Assembly’ (Часть №. 1002015-99р). This single component serves as the engine’s skeletal backbone, housing all primary moving parts and providing the rigid structure needed to withstand immense combustion pressures. It is the core of the FAW Cylinder block assembly.

Pressed into this main block are six ‘Cylinder Liners’ (1002016-81Д). These are a prime example of a ‘smallest serviceable unit’. These liners are of a “wet liner” дизайн, meaning their outer surfaces are in direct contact with the engine’s coolant. This design provides superior heat transfer but relies on a precision seal.

This sealing is accomplished by the ‘O-ring Rubber Seals’ (1002017-81D and 1002019-81D). The parts list calls for 12 of one type and 6 of another, indicating a multi-seal-per-liner strategy to prevent high-pressure coolant from entering the oil sump, or combustion gases from entering the cooling system. Replacing these seals is a critical step during any engine overhaul of the FAW Cylinder block assembly.

The crankshaft is supported within the FAW Cylinder block assembly by a set of precision bearings. The parts list identifies seven ‘Upper Main Bearing Shells’ (1002031-81Д) and seven ‘Lower Main Bearing Shells’ (1002032-81Д). The upper shells are seated in the block itself, while the lower shells are seated in the main bearing caps (which were detailed in the previous block-only assembly). These shells are designed to support the crankshaft on a microscopic film of oil, preventing metal-to-metal contact.

In addition to rotational support, the crankshaft’s axial movement (forward and backward) must be precisely controlled. This is the job of the ‘Thrust Plates’ (1002036-53Д). This set of four plates, or washers, is installed at a specific main bearing journal (typically the center one) to manage the thrust load generated by the clutch and helical-cut gears. Their thickness is critical, and wear on these components can lead to serious engine damage. This demonstrates the level of detail required when servicing the FAW Cylinder block assembly.

A critical, and often overlooked, component within the modern heavy-duty FAW Cylinder block assembly is the ‘Piston Cooling Nozzle Assembly’ (1002210-81Д). This parts list calls for six of these assemblies, one for each cylinder. The function of these nozzles is vital to the engine’s longevity and performance, especially under heavy load.

These nozzles are strategically positioned in the engine’s main oil gallery and are aimed at the underside of the piston crowns. When the engine is running, they spray a continuous, high-pressure jet of oil onto this extremely hot surface. This oil spray serves two primary purposes: firstly, it directly cools the piston, pulling heat away from the piston crown and ring lands. This prevents the piston from overheating, expanding excessively, and seizing in the cylinder liner.

Во-вторых, this cooling action prevents the oil in the piston ring grooves from coking (burning) and turning to hard carbon. Coked rings will stick, leading to a loss of compression, excessive oil consumption, and high blow-by, which ultimately results in engine failure. Поэтому, the proper function of these six nozzles is absolutely essential.

Each nozzle is secured to the block by a single ‘Bolt – Piston Cooling Nozzle Assembly’ (1002214A53D-S). These six bolts are critical fasteners. The nozzles themselves often contain a check valve that only opens above a certain oil pressure, ensuring the engine’s main bearings are prioritized during start-up and at low idle, when oil pressure is at its lowest. Servicing the FAW Cylinder block assembly requires careful inspection of these nozzles for blockage or damage.

The FAW Cylinder block assembly must be sealed from the external environment and provide mounting points for various auxiliary systems. The ‘Crankshaft Front Oil Seal Seat’ (1002056-81Д) is a key component that houses the front main seal, preventing oil from escaping the crankcase.

At the front of the engine, the ‘Gear Chamber Cover Plate’ (1002076-81Д) seals the timing gear compartment. At the rear, a complex part listed as ‘Gear Chamber Cover-Flywheel Housing’ (1002061-1509) provides the structural link between the engine block and the transmission’s flywheel housing. Other components like the ‘Cover Plate-Flywheel Housing’ (1002067-29Д) and ‘Pointer Flywheel Housing’ (1002066-29Д) complete this assembly, the latter being used for setting engine timing.

A complex assembly like the FAW Cylinder block assembly is held together by a vast array of specialized fasteners. The parts list details numerous ‘Hex Flange Bolts’. These are categorized into ‘Fine Rod (R тип)’ (НАПРИМЕР., Q1821055, Q18214130, Q18214120) and ‘Coarse Rod (Стандартный тип)’ (НАПРИМЕР., Q1841020, Q1841230, Q1840816, Q1841025). This distinction is critical, as “R тип” bolts often have a specific shank design for precise alignment or shear strength, while standard bolts are used for general clamping.

The list also includes 12 ‘Stud Bolts’ (1002043-2000), which are typically used for high-temperature or high-stress mounting points like the exhaust or intake manifolds, allowing for more consistent clamping force. Other miscellaneous hardware includes the ‘Rear Lifting Lug’ (1002044-81Д), the ‘Nameplate’ (1002091-29Д) for identification, and the four ‘Nameplate Rivets’ (Q541026) to secure it to the block.

The following table provides the complete, detailed breakdown of all components identified in the ‘Cylinder Block Assembly’ diagram for the FAW CA4251P66K24T1A3E5 tractor. Use these part numbers for accurate ordering and service.

| Mark | Часть №. | Наименование | Количество |

|---|---|---|---|

| 1 | Q1821055 | Гекс -фланцевой болт, Fine Rod (R тип) | 9 |

| 2 | 1002056-81Д | Crankshaft Front Oil Seal Seat | 1 |

| 3 | 1002032-81Д | Lower Main Bearing Shell | 7 |

| 4 | 1002031-81Д | Upper Main Bearing Shell | 7 |

| 5 | 1002015-99р | Блок цилиндров в сборе | 1 |

| 6 | 1002017-81Д | O-ring Rubber Seal | 12 |

| 7 | 1002019-81Д | O-ring Rubber Seal | 6 |

| 8 | 1002016-81Д | Cylinder Liner | 6 |

| 9 | Q541026 | Заклепка на плит | 4 |

| 10 | 1002091-29Д | Паспортная табличка | 1 |

| 11 | 1002076-81Д | Gear Chamber Cover Plate | 1 |

| 12 | Q1841020 | Гекс -фланцевой болт, Coarse Rod (Стандартный тип) | 3 |

| 13 | 1002061-1509 | Gear Chamber Cover-Flywheel Housing | 1 |

| 14 | 1006056-53D-S | Болт – Intermediate Timing Gear Shaft | 2 |

| 15 | Q18214110 | Гекс -фланцевой болт, Fine Rod (R тип) | 3 |

| 16 | 1002044-81Д | Rear Lifting Lug | 1 |

| 17 | Q1840612 | Гекс -фланцевой болт, Coarse Rod (Стандартный тип) | 2 |

| 18 | 1002068-29Д | Затыкать – Flywheel Housing | 1 |

| 19 | Q2140606 | Поперечный встроенный поддон винт | 2 |

| 20 | 1002066-29Д | Указатель – Flywheel Housing | 1 |

| 21 | Q18214130 | Гекс -фланцевой болт, Fine Rod (R тип) | 1 |

| 22 | Q1841230 | Гекс -фланцевой болт, Coarse Rod (Стандартный тип) | 2 |

| 23 | 1002043-2000 | Stud Bolt | 12 |

| 24 | Q18214120 | Гекс -фланцевой болт, Fine Rod (R тип) | 10 |

| 25 | 1002067-29Д | Крышка тарелки – Flywheel Housing | 1 |

| 26 | Q1840816 | Гекс -фланцевой болт, Coarse Rod (Стандартный тип) | 2 |

| 27 | Q1841025 | Гекс -фланцевой болт, Coarse Rod (Стандартный тип) | 6 |

| 28 | 1002036-53Д | Thrust Plate | 4 |

| 29 | 1002214A53D-S | Болт – Piston Cooling Nozzle Assembly | 6 |

| 30 | 1002210-81Д | Piston Cooling Nozzle Assembly | 6 |

The specifications for the FAW Cylinder block assembly are best understood in the context of its application. This is not just a single part, but a complex system of components, as detailed in this guide.

| Vehicle Application | FAW Jiefang CA4251P66K24T1A3E5 6×4 Tractor |

| Component Group | Cylinder Block Assembly and Components |

| Parent Part Number | 1002015-99р (Блок цилиндров в сборе) |

| Cylinder Liners | 6 (Часть №. 1002016-81Д), Wet-Liner Type |

| Main Bearing Shells | 7 Upper (1002031-81Д), 7 Lower (1002032-81Д) |

| Piston Cooling System | 6x Piston Cooling Nozzle Assembly (1002210-81Д) | Words

| Crankshaft Axial Control | 4x Thrust Plate (1002036-53Д) |

| Primary Function | Houses all core engine components, including liners, коленчатый вал, and pistons. Manages internal lubrication and coolant flow. Forms the primary structure of the engine. |

FAW parts, including the Cylinder Block Assembly, are packaged with care to ensure safe delivery. Each component is secured in protective materials to prevent damage during transit. The logistics network guarantees timely shipments worldwide, supporting efficient maintenance operations. Below is an image illustrating the standard packaging for FAW truck parts, showcasing the attention to detail in handling and storage.

This packaging approach minimizes the risk of corrosion or impact damage, ensuring that parts like the FAW Cylinder Block Assembly arrive in perfect condition. Customers can rely on FAW’s logistics for consistent quality and reliability.