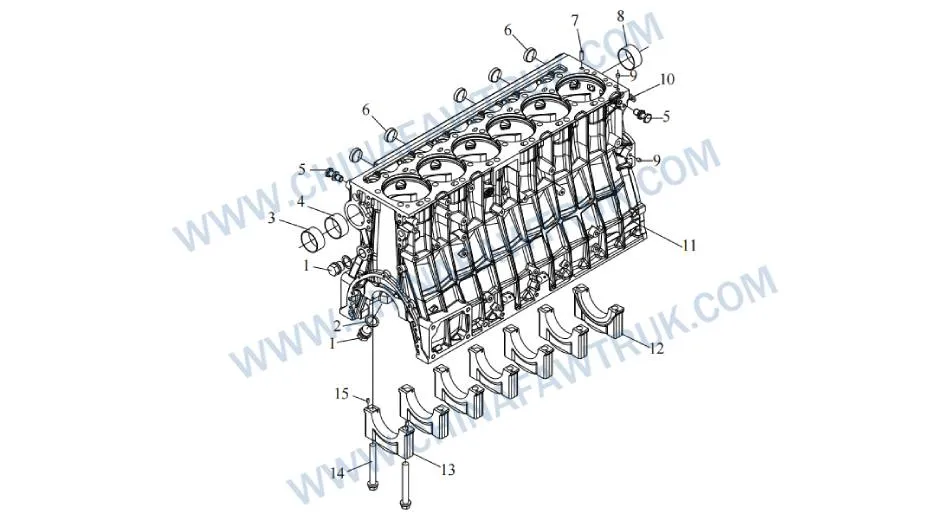

The FAW Cylinder Block represents the heart of the powerful CA3250P66K2L1T1E 6×4 dump truck manufactured by FAW Jiefang. This comprehensive exploded view guide provides an intricate breakdown of the cylinder block assembly, systematically disassembling large structural components down to the smallest serviceable repair units. Our detailed analysis covers everything from major castings to procurement items, enabling maintenance technicians to identify, service, and replace individual components with precision. Understanding the complete FAW Cylinder Block architecture is essential for optimal engine performance, долговечность, and efficient repair operations in demanding working conditions.

Disassembling the FAW Cylinder Block requires a methodical approach that begins with removing external components and progresses to internal elements. The process involves systematically separating large structural assemblies into their smallest repairable units, ensuring each component can be individually inspected, serviced, or replaced. Key disassembly stages include removing the cylinder head, поршни, liners, and internal components like camshaft bushings and oil seals.

The FAW Cylinder Block design emphasizes modular construction, allowing for efficient breakdown without compromising structural integrity. This modular approach significantly reduces repair time and costs by enabling targeted component replacement rather than full assembly overhaul. Regular maintenance following this disassembly sequence can prevent catastrophic engine failures and extend the operational lifespan of your FAW truck.

Technicians should follow the exploded view diagram precisely, referring to the parts list for accurate identification. Each component in the FAW Cylinder Block assembly serves a critical function, and proper disassembly ensures these elements can be thoroughly inspected for wear, damage, or potential failure points before reassembly.

This comprehensive parts list for the FAW Cylinder Block details every component visible in the exploded view diagram. Each part is identified by its official part number, description, and quantity required for the complete assembly. This reference enables accurate identification, ordering, and replacement of individual components during maintenance procedures.

| Part Number | Наименование | Количество |

|---|---|---|

| Q/WC3413-1994 | Hex Head Plug M27×2 | 2 |

| Вопрос/WC3403-1994 | Медная шайба 27 × 38 | 2 |

| 1006024A29D | Front Camshaft Bushing | 1 |

| 1006028A29D | Intermediate Camshaft Bushing | 5 |

| 1002021-29Д | Подъемная болт | 1 |

| Q72240 | Bowl Shape Plug | 1 |

| 1002022-36Д | Втулка сальника – Cylinder Block | 2 |

| 1006029A29D | Rear Camshaft Bushing | 5 |

| 1002023-36Д | Затыкать – Cylinder Block | 1 |

| Q72224 | Bowl Shape Plug | 1 |

| 1002014-36Д | Cylinder Block | 2 |

| 1002012-36Д | Rear Main Bearing Cap | 1 |

| 1002011-36Д | Main Bearing Cap | 1 |

| 1002013-36Д | Главный подшипник | 14 |

| Q5210612 | Цилиндрический штифт | 14 |

This detailed FAW Cylinder Block parts list serves as an essential reference for maintenance operations. Each component is engineered to precise specifications, ensuring reliable performance under the demanding conditions typical of heavy-duty dump truck applications. When ordering replacement parts, always verify part numbers against this official list to guarantee compatibility and optimal performance of your FAW Cylinder Block assembly.

The FAW Cylinder Block for the CA3250P66K2L1T1E model incorporates advanced engineering features designed specifically for heavy-duty applications. The following technical parameters provide essential information for proper installation, maintenance, и проверка совместимости. These specifications ensure the FAW Cylinder Block meets the rigorous demands of construction and mining operations where reliability is paramount.

| Параметр | Спецификация |

|---|---|

| Модель автомобиля | CA3250P66K2L1T1E |

| Engine Configuration | 6-Cylinder In-Line Diesel |

| Смещение | 7.7 Литры |

| Bore Diameter | 108 мм |

| Stroke Length | 130 мм |

| Compression Ratio | 17.5:1 |

| Block Material | High-Strength Gray Cast Iron |

| Масса | Approximately 285 кг |

| Cooling System | Pressurized Water Cooling |

| Maximum Cylinder Pressure | 180 bar |

| Liner Type | Wet Type Cylinder Liners |

| Main Bearing Cap Fasteners | 14 High-Strength Bolts |

These technical specifications demonstrate the robust construction and engineering excellence of the FAW Cylinder Block. Designed to withstand extreme operating conditions, the FAW Cylinder Block ensures reliable performance throughout its service life. Regular maintenance according to these parameters will maximize durability and minimize downtime for your FAW truck operations.

Proper maintenance of the FAW Cylinder Block is essential for ensuring long-term reliability and performance of your CA3250P66K2L1T1E dump truck. Begin with regular visual inspections checking for cracks, коррозия, or surface damage, particularly around high-stress areas such as cylinder walls and main bearing supports. Use the exploded view diagram as a reference during disassembly to ensure proper component identification and handling.

When servicing the FAW Cylinder Block, pay special attention to camshaft bushings, which require precise alignment during installation. The front, intermediate, and rear camshaft bushings must be properly seated to ensure optimal lubrication and minimal wear. Сходным образом, main bearing caps and bolts should be torqued to manufacturer specifications using the correct sequence to maintain structural integrity.

Regular replacement of sealing components like bowl shape plugs and oil seal sleeves is crucial for preventing fluid leaks and maintaining proper pressure within the FAW Cylinder Block assembly. Always use genuine FAW replacement parts to ensure compatibility and performance. Following a scheduled maintenance program based on operating hours will significantly extend the service life of your FAW Cylinder Block and prevent unexpected downtime.

The FAW Cylinder Block offers numerous advantages that contribute to the overall performance and durability of FAW trucks. Its robust construction using high-strength gray cast iron provides exceptional resistance to thermal stress and mechanical loads, ensuring reliable operation in the most demanding conditions. The modular design allows for targeted repairs and component replacement, significantly reducing maintenance costs and downtime.

Precision-engineered components within the FAW Cylinder Block assembly, such as the multiple camshaft bushings and cylindrical pins, ensure optimal alignment and reduced vibration throughout the engine’s operational range. This precision engineering translates to improved fuel efficiency, сокращение выбросов, and extended service intervals. The comprehensive parts availability and detailed documentation further enhance the maintainability of the FAW Cylinder Block, making it an excellent choice for fleet operators seeking reliability and cost-effective operation.

Кроме того, the FAW Cylinder Block is designed with serviceability in mind, featuring accessible components and clear identification markers that simplify maintenance procedures. This thoughtful design approach reduces the skill level required for routine servicing, enabling more technicians to perform quality maintenance on FAW engines. The result is a cylinder block assembly that delivers exceptional value through its combination of durability, производительность, and maintainability.