Welcome to this critical technical guide on the FAW Clutch Control Mechanism, the complete hydraulic and pneumatic actuation system for the FAW Jiefang CA4251P66K24T1A3E5 6×4 diesel semi-trailer tractor. This system is the vital link between the driver’s foot and the engine’s clutch.

ال FAW Clutch Control Mechanism هو “logic” system designed for one purpose: to multiply the force from the driver’s pedal, making it possible to disengage the massive, high-torque clutch. It uses a ‘Clutch Booster Assembly’ (1602305A70A) that is powered by the truck’s air brake system to provide this power assist.

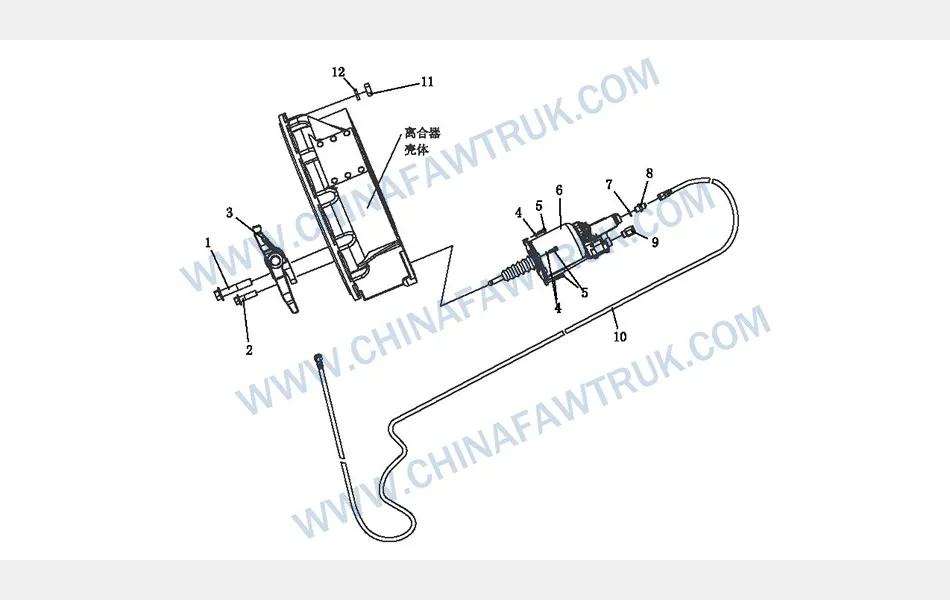

This guide is an essential resource for professional technicians and fleet managers. We will deconstruct the entire FAW Clutch Control Mechanism into its 12 serviceable components, including the booster, the release fork, the hydraulic piping, and all critical fasteners and seals.

The heart of the FAW Clutch Control Mechanism is the ‘Clutch Booster Assembly’ (1602305A70A). This is the “power steering” for the clutch. Disengaging a heavy-duty truck clutch requires thousands of pounds of force, which is impossible for a driver to generate with their leg alone. This booster assembly is an air-over-hydraulic unit that multiplies the driver’s effort.

**How it works:** ال FAW Clutch Control Mechanism‘s logic is simple. When the driver presses the clutch pedal, it sends a small amount of hydraulic fluid (brake fluid) from the clutch master cylinder into this booster. This small hydraulic pressure opens an internal air valve.

This valve then releases a large volume of high-pressure air (100+ PSI) from the truck’s main air brake tanks. This high-pressure air pushes on a large piston inside the booster, which in turn pushes a hydraulic piston, sending a massive, amplified hydraulic force out of the booster and to the clutch fork. هذا “logic” of using a small hydraulic signal to control a large pneumatic force is what makes the FAW Clutch Control Mechanism so effective, reducing pedal effort by 70% أو أكثر.

A failing FAW Clutch Control Mechanism booster is a common fault. It can fail internally, causing the clutch pedal to become rock-hard and impossible to press. It can also fail by leaking air from its seals, or by allowing hydraulic fluid to leak into the air system (or vice-versa). ال FAW Clutch Control Mechanism is typically replaced as a complete assembly.

The ‘Release fork & bracket assembly’ (1602420A70A) is the “muscle” of the FAW Clutch Control Mechanism. This is a heavy-duty, forged steel lever that pivots on a bracket inside the transmission’s bell housing.

Its function is to transfer the amplified force from the ‘Clutch Booster Assembly’ to the clutch’s ‘Release Bearing’ (the “throw-out bearing”). The booster’s push rod presses on the outside of this fork. The fork then pivots, and the “forked” end on the inside of the bell housing slides the release bearing forward along the transmission shaft.

This forward motion is what presses the bearing against the spinning pressure plate, disengaging the clutch. This fork and its pivot bracket are under immense, repeated stress. Wear on the pivot points or “وسادات” where the fork touches the bearing is a common issue that can lead to a “spongy” أو “soft” pedal, or a clutch that will not fully disengage, making it hard to shift. This is a critical mechanical link in the FAW Clutch Control Mechanism.

The hydraulic “piping” of the FAW Clutch Control Mechanism is responsible for transmitting the fluid. This system uses brake fluid, which is non-compressible.

The ‘Pipe assembly-clutch’ (1602200-90ر) is the main hydraulic line. It is a pre-bent, rigid steel pipe with flexible, high-pressure rubber sections at each end. This flexible design is critical, as it must absorb the constant vibration and movement of the engine/transmission relative to the stationary truck cab (where the master cylinder is).

The ‘Straight pipe joint assembly’ (1602325-1500) and ‘Pipe joint’ (1602241A70A) are the high-pressure adapter fittings that connect this main pipe assembly to the ‘Clutch Booster Assembly’ (1602305A70A). A leak in any of these lines or fittings will introduce air into the hydraulic side of the FAW Clutch Control Mechanism.

Air in a hydraulic line is a critical failure. Because air is compressible, pressing the clutch pedal will only “squish” the air bubble instead of moving the fluid. This results in a “dead” pedal that goes straight to the floor with zero resistance, leaving the driver unable to disengage the clutch. Bleeding this air from the FAW Clutch Control Mechanism is a key maintenance procedure.

The entire FAW Clutch Control Mechanism is a high-pressure system that relies on its seals and fasteners. The ‘Seal washer’ (1602242A70A) is a critical, single-use component. This is a “crush washer,” likely made of soft copper or aluminum, used to seal one of the high-pressure banjo-bolt fittings (like 1602241A70A). It must be replaced to prevent leaks.

The mounting hardware is also specialized. The ‘Hex head flange bolt’ (Q1851890T and Q1851450T) and ‘Hex head bolt’ (CQ1500825) are high-tensile fasteners used to secure the ‘Release fork & bracket assembly’ and the ‘Clutch Booster Assembly’ to the transmission bell housing. ال “شفة” heads distribute the load to prevent cracking the aluminum housing.

ال 12 ‘Hex nut’ (CQ34010) و 12 ‘Spring gasket’ (س40310) units are likely used for the ‘Pipe assembly-clutch’ (1602200-90ر) and its support brackets. The spring gaskets (lock washers) are vital for preventing the nuts from vibrating loose, which would lead to a fluid leak or a fractured pipe. This robust hardware is essential for the long-term reliability of the FAW Clutch Control Mechanism.

The following table provides the complete, detailed breakdown of all 12 components identified in the ‘Clutch Control Mechanism’ diagram for the FAW CA4251P66K24T1A3E5 tractor. A fully-functional FAW Clutch Control Mechanism is essential for safe operation.

| Mark | الجزء لا. | جزء اسم | كمية |

|---|---|---|---|

| 1 | Q1851890T | Hex head flange bolt | 1 |

| 2 | Q1851450T | Hex head flange bolt | 1 |

| 3 | 1602420A70A | Release fork & bracket assembly | 1 |

| 4 | س40308 | Spring gasket | 4 |

| 5 | CQ1500825 | Hex head bolt | 4 |

| 6 | 1602305A70A | Clutch Booster Assembly | 1 |

| 7 | 1602242A70A | Seal washer | 1 |

| 8 | 1602241A70A | Pipe joint | 1 |

| 9 | 1602325-1500 | Straight pipe joint assembly | 1 |

| 10 | 1602200-90ر | Pipe assembly-clutch | 1 |

| 11 | CQ34010 | الجوز السداسي | 12 |

| 12 | س40310 | Spring gasket | 12 |

The specifications for the FAW Clutch Control Mechanism are defined by its function as a hybrid air-over-hydraulic assist system. The entire FAW Clutch Control Mechanism is designed to multiply pedal force.

| Vehicle Application | FAW Jiefang CA4251P66K24T1A3E5 6×4 جرار |

| Component Group | FAW Clutch Control Mechanism |

| System Type | Pneumatic Assist (Air-over-Hydraulic) |

| Main Actuator | 1x Clutch Booster Assembly (1602305A70A) |

| Mechanical Linkage | 1x Release fork & bracket assembly (1602420A70A) |

| Hydraulic Line | 1x Pipe assembly-clutch (1602200-90ر) |

| Hydraulic Fluid | زيت الفرامل (على سبيل المثال, DOT 4) |

| Pneumatic Source | Vehicle’s Main Air Brake System |

| Critical Seal | 1x Seal washer (1602242A70A) |

| Primary Function | To use pneumatic pressure to multiply the driver’s hydraulic pedal force, enabling disengagement of the heavy-duty clutch. |

FAW parts, including the Cylinder Block Assembly, are packaged with care to ensure safe delivery. Each component is secured in protective materials to prevent damage during transit. The logistics network guarantees timely shipments worldwide, supporting efficient maintenance operations. Below is an image illustrating the standard packaging for FAW truck parts, showcasing the attention to detail in handling and storage.

This packaging approach minimizes the risk of corrosion or impact damage, ensuring that parts like the FAW Cylinder Block Assembly arrive in perfect condition. Customers can rely on FAW’s logistics for consistent quality and reliability.