Welcome to this vital technical guide on the FAW Camshaft Logic Assembly, the component that acts as the “brain” of the valvetrain for the FAW Jiefang CA4251P66K24T1A3E5 6×4 diesel semi-trailer tractor. This assembly dictates the engine’s breathing and performance.

The FAW Camshaft Logic Assembly is responsible for the precise, non-negotiable timing of all intake and exhaust valves. Its “logic” is ground into its very design, ensuring that each cylinder draws in fresh air and expels exhaust gases at the exact millisecond required for optimal power, эффективность, and emissions control.

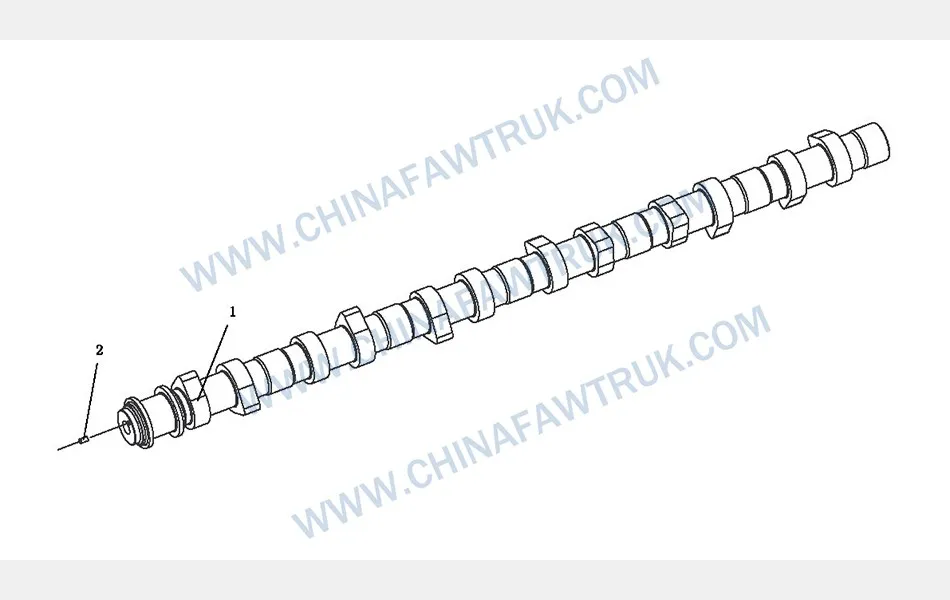

This guide is an essential resource for professional engine technicians, machine shops, and parts specialists. We will deconstruct the entire FAW Camshaft Logic Assembly into its two core serviceable units: the camshaft itself and its critical dowel pin. Understanding this system is fundamental to any top-end engine service.

The core of the FAW Camshaft Logic Assembly is the ‘Camshaft’ (1006016-81Д). This is a single, highly engineered component that controls the entire valvetrain. In the CA4251P66K24T1A3E5 engine, this is an Overhead Camshaft (OHC), meaning it sits at the top of the cylinder head, allowing for more direct and precise valve actuation. This single shaft is responsible for opening and closing all 24 клапаны (12 прием, 12 exhaust) in the six-cylinder engine.

The material and manufacturing of this camshaft are critical. It is typically forged from a single billet of high-carbon steel or cast from a high-strength “chilled iron.” After the basic shape is formed, it undergoes a complex machining and hardening process. The “logic” of the FAW Camshaft Logic Assembly is ground into the precise, eccentric shape of its 12 intake and 12 exhaust lobes.

Each of these cam lobes is induction-hardened to create a glass-like, wear-resistant surface, while the core of the shaft remains more ductile to resist snapping under torsional stress. The lobes themselves are designed with a specific “profile” that dictates two things: “lift” (how far the valve opens) и “duration” (how long the valve stays open). The profile on this FAW Camshaft Logic Assembly is optimized for a heavy-duty diesel engine, prioritizing high lift and short duration to create the low-RPM torque that is characteristic of this tractor.

This camshaft rides on the seven precision bearing saddles that are line-bored into the cylinder head and secured by the camshaft caps (as detailed in a previous guide). The polished surfaces between the cam lobes are the bearing journals. These journals ride on a hydrodynamic film of oil, just thousandths of an inch thick. The integrity of this oil film is the single most important factor in the long life of the FAW Camshaft Logic Assembly. Any oil starvation or contamination will lead to scoring on these journals, destroying both the camshaft and the cylinder head.

The second and final component of the FAW Camshaft Logic Assembly is the ‘Dowel Pin’ (Q5210614). This single cylindrical pin may be the smallest part in the assembly, but it is one of the most critical components for engine survival.

This hardened steel pin is pressed into a precision-drilled hole at the “snout” (передний) of the camshaft (1006016-81Д). Its purpose is to “ключ” или “index” the main camshaft timing gear. The timing gear, which is driven by the crankshaft via a chain or gear train, slides onto the snout of the camshaft. This dowel pin fits into a corresponding slot or hole in the timing gear.

This pin performs a non-negotiable function: it locks the camshaft gear in a single, exact position relative to the cam lobes. This ensures that when a technician aligns the timing marks on the gear train (setting “engine time”), the lobes of the FAW Camshaft Logic Assembly are *also* perfectly aligned with the pistons’ positions.

Without this pin, the camshaft timing would be a matter of guesswork, and the high-torque bolt at the end of the cam could slip, allowing the cam timing to “walk.” If this happens, the engine’s “logic” is destroyed. The valves would open at the wrong time, striking the tops of the pistons and causing catastrophic, engine-ending damage. The integrity of this single pin is the lynchpin of the entire FAW Camshaft Logic Assembly.

The FAW Camshaft Logic Assembly does not directly touch the valves. As an overhead cam (OHC) дизайн, it actuates the valves through an intermediary mechanism, typically rocker arms or roller-followers. As the camshaft spins, the eccentric lobe rotates and its peak, или “nose,” pushes down on the rocker arm. This rocker arm then pivots, pushing down and opening the valve against the pressure of a heavy valve spring.

This entire interface is a high-friction, high-wear area. The surface of the cam lobe and the surface of the rocker arm (often a roller) are two of the most highly-stressed surfaces in the entire engine. This is why proper oiling is so critical. The oil channels within the FAW Camshaft Logic Assembly and cylinder head are designed to flood this contact point with a constant stream of high-pressure oil.

Any failure in oil supply (low pressure, wrong viscosity, or contamination) will cause this oil film to break down. The result is rapid, galling wear, where the hardened surfaces of the cam lobe and rocker arm are “wiped” flat. Этот “flat cam” is a common end-of-life failure for many engines. А “wiped lobe” on the FAW Camshaft Logic Assembly will no longer be able to provide the full valve “lift,” meaning the valve will not open fully. This results in a cylinder that cannot “breathe” properly, leading to a “dead” цилиндр, misfiring, low power, and high smoke.

Поэтому, а FAW Camshaft Logic Assembly is a component that demands meticulous cleanliness during installation and the use of high-quality engine oil throughout its service life. When installing a new FAW Camshaft Logic Assembly, it is mandatory to use a special, high-molybdenum assembly lube on every lobe and bearing journal to protect them during the critical first few seconds of operation before the oil pressure builds.

Diagnosing a fault in the FAW Camshaft Logic Assembly typically begins with symptoms like a persistent misfire on one or more cylinders, а “ticking” или “tapping” sound from the top of the engine, or a gradual loss of power over time.

After removing the cylinder head cover, a technician can visually inspect the cam lobes for any visible scoring, pitting, or discoloration (а “blued” lobe indicates extreme heat from oil starvation). A more precise method involves using a dial indicator to measure the “lift” of each cam lobe as the engine is rotated by hand. The measured lift is then compared to the factory specifications. Any lobe that provides less lift than the specification is worn out, and the FAW Camshaft Logic Assembly must be replaced.

It is critical to remember that the camshaft is part of a matched set. If the FAW Camshaft Logic Assembly (1006016-81Д) is found to be damaged, it is almost certain that the components it rides on (the rocker arms) are also damaged. Simply replacing the cam without replacing the worn rockers will result in the new cam being destroyed in a very short amount of time. A complete top-end job requires a full inspection of the entire valvetrain associated with the FAW Camshaft Logic Assembly.

The following table provides the complete, detailed breakdown of all components identified in the ‘Camshaft Logic Assembly’ diagram for the FAW CA4251P66K24T1A3E5 tractor. Этот FAW Camshaft Logic Assembly is the core of the engine’s valvetrain.

| Mark | Часть №. | Наименование | Количество |

|---|---|---|---|

| 1 | 1006016-81Д | Распределительный вал | 1 |

| 2 | Q5210614 | Dowel Pin | 1 |

The specifications for the FAW Camshaft Logic Assembly are defined by its function as the master controller for the engine’s valvetrain in a 6-cylinder OHC configuration. The entire FAW Camshaft Logic Assembly must be installed with precision.

| Vehicle Application | FAW Jiefang CA4251P66K24T1A3E5 6×4 Tractor |

| Component Group | FAW Camshaft Logic Assembly |

| Camshaft Part No. | 1006016-81Д |

| Dowel Pin Part No. | Q5210614 |

| Engine Type | 6-Цилиндр, Overhead Cam (OHC), 24-Valve Diesel |

| Lobe Count | 24 (12 Впуск, 12 Exhaust) |

| Материал (Распределительный вал) | Forged Steel Billet or Chilled Cast Iron |

| Hardening Process | Induction Hardening on Lobes and Journals |

| Primary Function | Precisely actuates all 24 engine valves (intake and exhaust) in the correct sequence and duration. |

FAW parts, including the Cylinder Block Assembly, are packaged with care to ensure safe delivery. Each component is secured in protective materials to prevent damage during transit. The logistics network guarantees timely shipments worldwide, supporting efficient maintenance operations. Below is an image illustrating the standard packaging for FAW truck parts, showcasing the attention to detail in handling and storage.

This packaging approach minimizes the risk of corrosion or impact damage, ensuring that parts like the FAW Cylinder Block Assembly arrive in perfect condition. Customers can rely on FAW’s logistics for consistent quality and reliability.