Welcome to this expert technical analysis of the FAW Expansion Tank, Pipework, Brackets system for the FAW Jiefang CA4251P66K24T1A3E5 6×4 diesel semi-trailer tractor. This assembly is the critical “overflow” and “deaeration” system for the engine’s high-pressure cooling circuit.

The FAW Expansion Tank, Pipework, Brackets assembly is a multi-part system that performs three vital functions: it provides a reservoir for coolant to expand into as it heats up, it traps and purges all air bubbles from the system (deaeration), and it serves as the high point for filling and checking the coolant level.

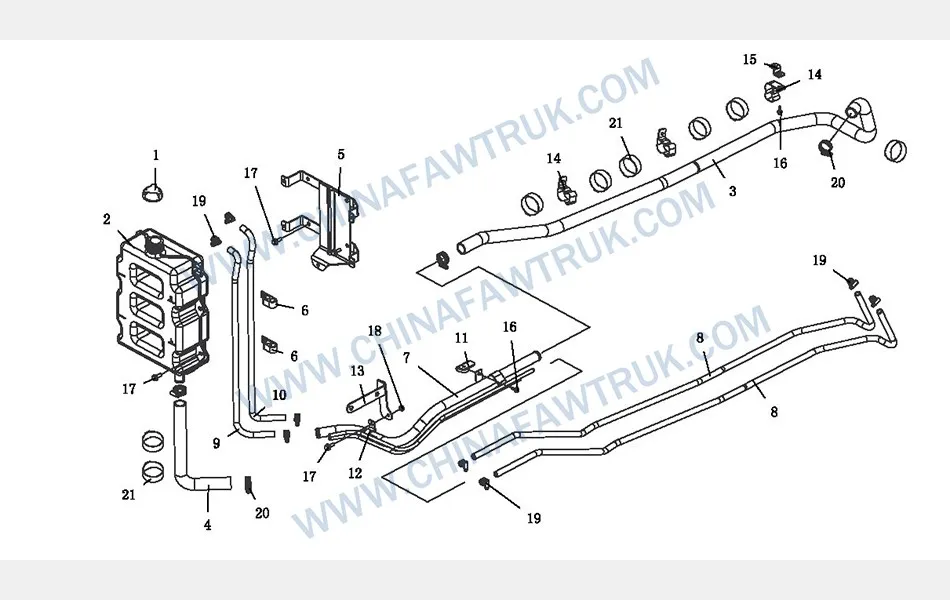

This in-depth guide is an essential resource for professional technicians, fleet managers, and parts specialists. We will deconstruct the entire FAW Expansion Tank, Pipework, Brackets system into its 21 serviceable components, including the ‘Expansion Tank Assembly’ (1311020-76A), its ‘Pressure Cap’ (1304010-50A), all connecting hoses, and the critical vibration-damping brackets.

The core of the FAW Expansion Tank, Pipework, Brackets system is the ‘Expansion Tank Assembly’ (1311020-76A). This is the high-point reservoir of the cooling system. It is a robust, translucent polymer (plastic) tank, allowing a technician to visually inspect the coolant level without opening the system.

This tank’s primary function is to manage thermal expansion. As the engine’s coolant heats up from 20°C to 95°C, it can expand in volume by 3-5%. The FAW Expansion Tank, Pipework, Brackets system provides the “air head” or empty space for this expanded coolant to move into. Without it, the expanding fluid would create immense pressure and rupture the radiator or hoses.

Secondly, this tank is the “deaeration” center. It is designed to be the highest point in the cooling circuit. Small “deaeration” lines from the radiator (1311061A377) and engine head (1311068-61B) feed into this tank. Any air bubbles or steam pockets from the engine are “bled” into this tank, where they are trapped. This ensures the engine block and water pump are always filled with 100% liquid coolant, preventing “hot spots” that can crack a cylinder head. This deaeration logic is a key function of the FAW Expansion Tank, Pipework, Brackets system.

The ‘Pressure Cap Assembly’ (1304010-50A) is the most critical “logic” component in the entire FAW Expansion Tank, Pipework, Brackets system. It is not just a lid; it is a sophisticated, spring-loaded, two-way valve.

**1. Pressure Valve (Raises Boiling Point):** The main function of this cap is to pressurize the entire cooling system (e.g., to 1.1 bar / 16 PSI). For every 1 PSI of pressure, the boiling point of water is raised by approximately 1.7°C (3°F). This 16-PSI cap raises the coolant’s boiling point from 100°C (212°F) to over 126°C (257°F). This is *essential* for a heavy-duty diesel engine, as it prevents the coolant from boiling (“cavitation”) around the hot cylinder liners, which would lead to immediate, catastrophic overheating. The large spring inside the cap holds this pressure.

**2. Vacuum Valve (Prevents Hose Collapse):** When the engine is turned off, the coolant (now at 95°C) begins to cool. As it cools, it contracts, creating a powerful *vacuum* inside the cooling system. This vacuum is strong enough to collapse the large, soft radiator hoses (like 1303021-74A). To prevent this, a small, reverse, “vacuum” valve in the center of the cap is pulled *open* by this vacuum, allowing air to be drawn *into* the FAW Expansion Tank, Pipework, Brackets assembly to equalize the pressure.

A faulty pressure cap is a very common and misdiagnosed cause of overheating. If its spring is weak, the system will not pressurize, and the engine will boil over at normal operating temperature. The FAW Expansion Tank, Pipework, Brackets system is entirely dependent on this one part.

The “Pipework” components of the FAW Expansion Tank, Pipework, Brackets are a network of hoses and pipes for returning and deaerating coolant.

**Deaeration (Air Bleed) Lines:** These are the small hoses that “bleed” air from the system. The ‘Deaeration hose’ (1311068-61B) and ‘Rear deaeration hose’ (1311069-61B) run from the high points of the engine (like the thermostat housing) to the top of the ‘Expansion Tank Assembly’. The ‘Radiator front deaeration hose’ (1311061A377) runs from the top of the radiator to the tank. These pipes ensure all trapped air is purged.

**Return Water Circuit:** This is the circuit that returns coolant from the vehicle’s “heater core” (which provides heat to the cab) and the fuel heater. This circuit is comprised of the ‘Return water hose’ (1311033-61B), ‘Front return water hose’ (1311038-61C), ‘Connecting pipe assembly’ (1311025-61C), and the ‘Steel return water pipe assembly’ (1311065-91W). This combination of flexible rubber hoses (to absorb engine vibration) and rigid steel pipes (for long, protected runs) is a key part of the FAW Expansion Tank, Pipework, Brackets system’s durability.

This entire network of “pipework” is held together with numerous ‘Worm Drive Hose Clamps’ (CQ67622B, CQ67640B) and ‘Plastic zip ties’ (T67420376) to ensure a leak-free, vibration-resistant setup for the FAW Expansion Tank, Pipework, Brackets.

The “Bracket” components of the FAW Expansion Tank, Pipework, Brackets are essential for protecting the system from vibration. The ‘Expansion Tank Bracket Assembly’ (1311040-61C) is the main “shelf” that bolts to the cab or chassis, holding the heavy, fluid-filled ‘Expansion Tank Assembly’.

The extensive piping is also rigidly supported. The ‘Front support bracket for return steel pipe’ (1311070-91W), ‘Rear support bracket for return steel pipe’ (1311075-91W), and ‘Deaeration pipe support bracket assembly’ (1311080-91W) are all used to clamp the long steel and rubber pipes.

This prevents the pipes from chaffing against the engine or frame, which would quickly wear a hole in them. The ‘Bracket’ (1311077-61B) and ‘Double-pipe clamp assembly’ (1311060-61B) are used to group and secure multiple hoses, keeping the FAW Expansion Tank, Pipework, Brackets system tidy and safe from moving parts.

The following table provides the complete, detailed breakdown of all 21 components identified in the ‘Expansion Tank, Pipework, Brackets’ diagram for the FAW CA4251P66K24T1A3E5 tractor. This FAW Expansion Tank, Pipework, Brackets system is key to engine thermal management.

| Mark | Part No. | Part Name | Quantity |

|---|---|---|---|

| 1 | 1304010-50A | Pressure Cap Assembly | 1 |

| 2 | 1311020-76A | Expansion Tank Assembly | 1 |

| 3 | 1311032-61B | Return water hose | 1 |

| 4 | 1311033-61B | Return water hose | 1 |

| 5 | 1311040-61C | Expansion tank bracket assembly | 1 |

| 6 | 1311060-61B | Double-pipe clamp assembly | 2 |

| 7 | 1311065-91W | Steel return water pipe assembly | 1 |

| 8 | 1311067-61B | Deaeration hose | 2 |

| 9 | 1311068-61B | Deaeration hose | 1 |

| 10 | 1311069-61B | Rear deaeration hose | 1 |

| 11 | 1311070-91W | Front support bracket for return steel pipe | 1 |

| 12 | 1311071A377 | Single-pipe clamp | 1 |

| 13 | 1311075-91W | Rear support bracket for return steel pipe | 1 |

| 14 | 1311077-61B | Flexible hose | 3 |

| 15 | 1311080-91W | Deaeration pipe support bracket assembly | 1 |

| 16 | CQ1460620 | Combination Bolt | 2 |

| 17 | CQ1460825 | Combination Bolt | 10 |

| 18 | CQ34008 | Hex nut | 1 |

| 19 | CQ34008 | Hex nut | 3 |

| 20 | CQ67622B | Worm Drive Hose Clamp B-Type | 8 |

| 21 | CQ67640B | Worm Drive Hose Clamp B-Type | 4 |

| 22 | T67420376 | Plastic Zip Tie | 8 |

| 23 | Q1840816 | Hex flange bolt, coarse rod (Standard Type) | 8 |

| 24 | Q1840825 | Hex flange bolt, coarse rod (Standard Type) | 2 |

| 25 | Q40108 | Gasket (Washer) | 2 |

| 26 | Q40308 | Spring gasket | 2 |

| 27 | T67420376 | Plastic Zip Tie | 2 |

The specifications for the FAW Expansion Tank, Pipework, Brackets system are defined by its function as the cooling system’s reservoir, pressurization, and deaeration hub. The FAW Expansion Tank, Pipework, Brackets assembly is key to engine thermal management.

| Vehicle Application | FAW Jiefang CA4251P66K24T1A3E5 6×4 Tractor |

| Component Group | FAW Expansion Tank, Pipework, Brackets |

| Main Tank Assembly | 1x (Part No. 1311020-76A) |

| Pressure Control | 1x Pressure Cap Assembly (1304010-50A) |

| System Type | Pressurized Deaeration / Expansion Reservoir |

| Deaeration Piping | Incl. 1311068-61B, 1311069-61B, 1311061A377 |

| Return Circuit Piping | Incl. 1311065-91W, 1311033-61B, 1311038-61C |

| Mounting System | Multiple Brackets (1311040-61C, 1311070-91W, etc.) |

| Primary Function | To compensate for coolant thermal expansion, remove air from the system, and provide a fill point. |

FAW parts, including the Cylinder Block Assembly, are packaged with care to ensure safe delivery. Each component is secured in protective materials to prevent damage during transit. The logistics network guarantees timely shipments worldwide, supporting efficient maintenance operations. Below is an image illustrating the standard packaging for FAW truck parts, showcasing the attention to detail in handling and storage.

This packaging approach minimizes the risk of corrosion or impact damage, ensuring that parts like the FAW Cylinder Block Assembly arrive in perfect condition. Customers can rely on FAW’s logistics for consistent quality and reliability.