Welcome to this critical technical guide on the FAW Urea Supply System Random Component Logic Assembly, a vital support system for the emissions control circuit on the FAW Jiefang CA4251P66K24T1A3E5 6×4 diesel semi-trailer tractor.

This FAW Urea Supply System Random Component Logic Assembly is not the main urea pump or tank, but rather the essential collection of “random components” that form the “logic” of the fluid handling. This system is responsible for the critical task of heating the urea (DEF) fluid using engine coolant, and for providing the fluid connection points for the return and filter circuits.

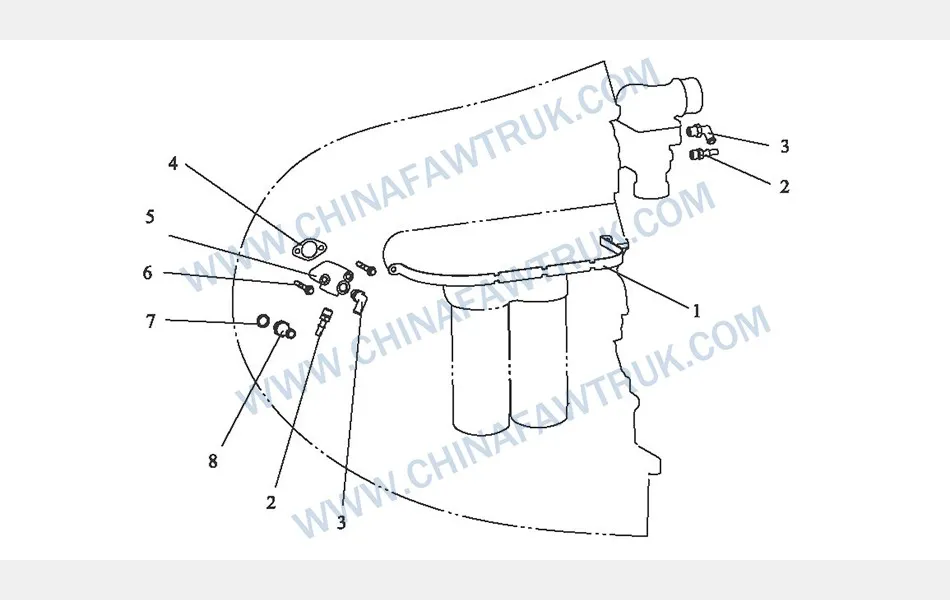

This guide is an indispensable resource for emissions technicians and fleet maintenance managers. We will deconstruct the entire FAW Urea Supply System Random Component Logic Assembly into its 8 smallest serviceable units, including the chassis-mounted bracket, the fluid joints for both coolant and urea, and the critical gaskets that keep these two fluids separate.

The primary “logic” of the FAW Urea Supply System Random Component Logic Assembly is thermal management. Diesel Exhaust Fluid (DEF), or urea, has a freezing point of -11°C (11°F). In cold climates, the urea in the tank will be a solid block of ice. To meet emissions standards, the truck must be able to thaw and inject this urea quickly.

This assembly is the heat exchanger. It taps into the engine’s main cooling system, which can be 80-90°C. The ‘Urea heating joint’ (1160406-2000) is the central “tap.” Hot engine coolant flows into this joint, which is connected to the ‘Circulating water joint (II)’ (1160404-51B) ports. These components create a “water jacket” that surrounds the urea filter. The hot coolant rapidly thaws and heats the urea as it passes through the filter, ensuring the SCR system is operational.

A failure in this part of the FAW Urea Supply System Random Component Logic Assembly is critical. If the coolant circuit leaks or becomes clogged, the urea will not be heated, and the truck will enter a “limp mode” due to non-compliance with emissions regulations. This heating function is the most important part of the FAW Urea Supply System Random Component Logic Assembly.

The FAW Urea Supply System Random Component Logic Assembly also provides the main connection points for the urea fluid itself. The parts list details two ‘Urea return joint’ (1160401-1063) units. In a modern SCR system, the urea pump constantly circulates the fluid from the tank to the injector module and back again.

This continuous circulation, especially through the heating element of the FAW Urea Supply System Random Component Logic Assembly, ensures the entire circuit is warm and ready for injection. These return joints are the fittings that allow the unused, warmed urea to be sent back to the tank, completing the loop.

The ‘Filter joint’ (1160403A99R), also called an “adapter joint,” is the main head component. This is the part that the main serviceable urea filter (which must be replaced periodically) threads onto. This entire assembly of joints and adapters must be made of highly corrosion-resistant materials, as urea is notoriously corrosive to metals like brass, copper, and standard steel. The correct material choice is a key specification of the FAW Urea Supply System Random Component Logic Assembly.

The entire FAW Urea Supply System Random Component Logic Assembly, including the filter and the fluid-filled heat exchanger, is a heavy component. It cannot be left to hang from its plumbing. The ‘Bracket’ (1160013-54W) is the structural backbone of the entire assembly.

This is a heavy-duty, stamped steel bracket that is designed to be bolted directly to the truck’s chassis frame rail. By mounting the FAW Urea Supply System Random Component Logic Assembly to the chassis, it is isolated from the constant, high-frequency vibration of the engine. This is a critical design choice.

If this system were bolted to the engine, the vibration would quickly fatigue and crack the rigid plastic or metal housings of the heater and filter, causing leaks. The bracket ensures the assembly is held securely in place and only subjected to road vibrations.

This bracket is secured to the chassis using the two ‘Hex flange bolt, coarse rod (Standard Type)’ (Q1840860) fasteners. The “flange” head of these bolts is essential, as it acts as an integrated washer to spread the clamping load and prevent the bolt from vibrating loose over tens of thousands of miles. This solid mounting is key to the longevity of the FAW Urea Supply System Random Component Logic Assembly.

This FAW Urea Supply System Random Component Logic Assembly handles two separate, incompatible fluids: engine coolant and urea (DEF). Keeping them separate is the job of the ‘Gasket-water pipe filter flange’ (1160402-51B). This is the main seal between the engine’s coolant circuit and the heating joint. A failure of this single, inexpensive gasket would be catastrophic, allowing high-pressure engine coolant to leak out or, worse, forcing coolant into the urea system, which would poison the SCR catalyst.

The second seal is the ‘Gasket ring’ (CQ72318T5). This is a precision O-ring or crush washer used to seal one of the fluid joints, most likely the ‘Filter joint’ (1160403A99R). This seal is what prevents the urea fluid from leaking. A urea leak is problematic because the fluid will crystallize into white, crusty deposits upon contact with air, which can clog the system.

Both of these gaskets are “single-use” items. They are designed to be crushed or compressed once to create a perfect seal. Re-using them upon servicing the FAW Urea Supply System Random Component Logic Assembly is a guaranteed way to cause a leak. Proper service of the FAW Urea Supply System Random Component Logic Assembly always includes replacing these seals.

The following table provides the complete, detailed breakdown of all 8 components identified in the ‘Urea Supply System Random Component Logic Assembly’ diagram for the FAW CA4251P66K24T1A3E5 tractor. This FAW Urea Supply System Random Component Logic Assembly is vital for emissions compliance.

| Mark | Part No. | Part Name | Quantity |

|---|---|---|---|

| 1 | 1160013-54W | Bracket | 1 |

| 2 | 1160401-1063 | Urea return joint | 2 |

| 3 | 1160404-51B | Circulating water joint (II) | 2 |

| 4 | 1160402-51B | Gasket-water pipe filter flange | 1 |

| 5 | 1160406-2000 | Urea heating joint | 1 |

| 6 | Q1840860 | Hex flange bolt, coarse rod (Standard Type) | 2 |

| 7 | CQ72318T5 | Gasket ring | 1 |

| 8 | 1160403A99R | Filter joint | 1 |

The specifications for the FAW Urea Supply System Random Component Logic Assembly are defined by its function as a fluid handling and heating system for the truck’s SCR emissions system. The FAW Urea Supply System Random Component Logic Assembly is a key support kit.

| Vehicle Application | FAW Jiefang CA4251P66K24T1A3E5 6×4 Tractor |

| Component Group | FAW Urea Supply System Random Component Logic Assembly |

| Primary System | Selective Catalytic Reduction (SCR) / DEF (Urea) System |

| Core Function | Urea (DEF) heating via engine coolant heat exchanger |

| Heating Circuit Joints | 1x (1160406-2000), 2x (1160404-51B) |

| Urea Fluid Joints | 2x Return (1160401-1063), 1x Filter (1160403A99R) |

| Main Gaskets | 1x Flange (1160402-51B), 1x Ring (CQ72318T5) |

| Mounting System | 1x Bracket (1160013-54W) with 2x Flange Bolts (Q1840860) |

| Associated Fluid | Diesel Exhaust Fluid (Urea) and Engine Coolant |

FAW parts, including the Cylinder Block Assembly, are packaged with care to ensure safe delivery. Each component is secured in protective materials to prevent damage during transit. The logistics network guarantees timely shipments worldwide, supporting efficient maintenance operations. Below is an image illustrating the standard packaging for FAW truck parts, showcasing the attention to detail in handling and storage.

This packaging approach minimizes the risk of corrosion or impact damage, ensuring that parts like the FAW Cylinder Block Assembly arrive in perfect condition. Customers can rely on FAW’s logistics for consistent quality and reliability.