Welcome to this comprehensive technical guide on the FAW Upper Right Centre Shaft Assembly Of The Main Box. This is a complete, load-bearing gear and shaft set for the main gearbox of the FAW Jiefang CA4251P66K24T1A3E5 6×4 diesel semi-trailer tractor.

O FAW Upper Right Centre Shaft Assembly Of The Main Box, also known as the “counter-shaft,” is one of the most critical components in a heavy-duty transmission. It is part of a “twin-countershaft” design, working in tandem with a second (lower left) shaft to split the engine’s torque, thereby doubling the gearbox’s strength.

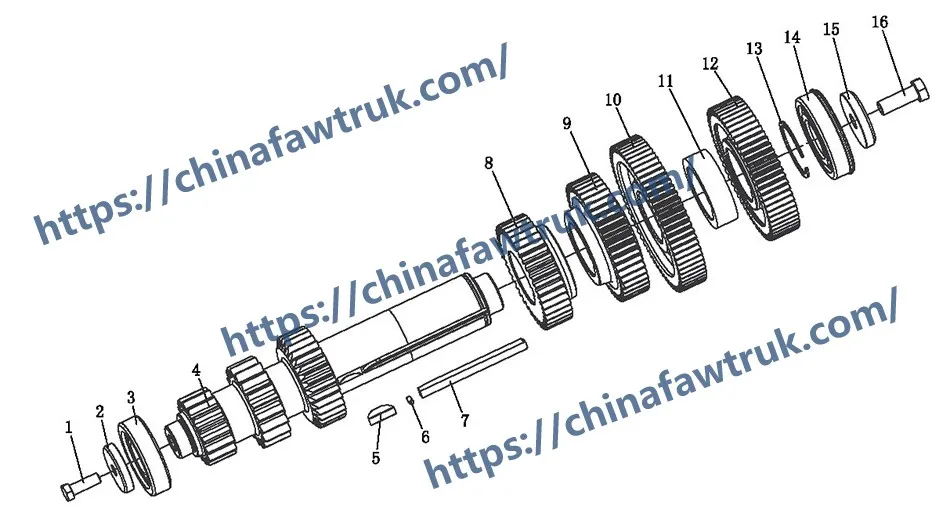

This in-depth guide is an essential resource for professional transmission technicians and parts specialists. We will deconstruct the entire FAW Upper Right Centre Shaft Assembly Of The Main Box into its 16 serviceable components, including the main ‘Countershaft’ (1701211-A9P), all of its drive gears, the critical bearings, and all associated locking hardware.

The main gearbox of this FAW tractor uses a **twin-countershaft** (ou “twin-shaft”) design. This is the gold standard for heavy-duty applications. Instead of one large countershaft handling 100% of the engine’s torque, the load is “split” 50/50 between two smaller, identical countershafts.

Esta montagem, o FAW Upper Right Centre Shaft Assembly Of The Main Box, is one of those two critical shafts. By splitting the torque, o “separating forces” (the forces of the gear teeth trying to push each other apart) are balanced. This dramatically reduces the stress on the transmission housing and the bearings, allowing the gearbox to be lighter, more compact, and significantly more durable.

O “logic” of this system requires that both the FAW Upper Right Centre Shaft Assembly Of The Main Box and its “Lower Left” twin are perfectly “timed” so that their helical gear teeth engage the main shaft gears at the exact same instant. If the timing is off by a single tooth, one shaft will take the entire load, leading to its rapid and catastrophic failure.

The backbone of the FAW Upper Right Centre Shaft Assembly Of The Main Box is the ‘Countershaft’ (1701211-A9P) em si. This is a single, massive, forged component made from high-carbon, case-hardened steel. It is designed to be the primary torque-bearing component in the main box.

Its function is to “counter” the rotation of the input shaft. The input shaft’s gear (see assembly 143) is in permanent, constant mesh with the “input drive gear” on this FAW Upper Right Centre Shaft Assembly Of The Main Box. This means that any time the clutch is engaged and the engine is spinning, this countershaft is also spinning.

The shaft itself is precision-machined with multiple “steps,” splines, and bearing journals. The splines are used to mount the various drive gears, while the journals provide a mirror-smooth, ultra-hard surface for the main roller bearings to ride on. A bent or twisted countershaft is a catastrophic failure that requires a full transmission rebuild, making the integrity of this core FAW Upper Right Centre Shaft Assembly Of The Main Box absolutely critical.

O “logic” of the FAW Upper Right Centre Shaft Assembly Of The Main Box is embodied in its set of fixed, constant-mesh drive gears. This parts list details the following:

These are the “drive” engrenagens. They are fixed (splined or press-fit) to the ‘Countershaft’ and are *always* spinning at the same speed as the shaft. They are in permanent, constant mesh with their corresponding “driven” engrenagens, which spin freely on the main shaft (o “segundo eixo”).

When the driver selects “3rd gear,” they are actually engaging a clutch (a “synchronizer”) that locks the *freewheeling 3rd gear* to the main shaft. The power flow is then from the input gear, to the FAW Upper Right Centre Shaft Assembly Of The Main Box, through this ‘3rd gear-countershaft’, to the main shaft, and out to the wheels. These helically-cut gears are designed for quiet, high-torque operation.

The entire FAW Upper Right Centre Shaft Assembly Of The Main Box is supported at both ends by heavy-duty bearings.

These bearings are protected by “baffles,” which are oil slingers. The ‘Baffle-countershaft front bearing’ (1701233-A7G) and ‘Baffle-countershaft rear bearing’ (1701233-A9P) are secured by ‘Hex head bolts’ (CQ1511235S, CQ1511645S). These discs spin with the shaft, flinging oil *away* from the bearing seals, preventing leaks and ensuring a long service life for the FAW Upper Right Centre Shaft Assembly Of The Main Box.

Finalmente, the ‘Circlip-reduction gear’ (1701229-A7G) and ‘Spacer’ (1701247-A7K) are used to lock the ‘Reduction gear’ in its precise location on the shaft. The ‘Woodruff Key’ (1701226-A7G), ‘Flat Key’ (1701228-A7G), and ‘Spring dowel pin’ (Q5280510) are all used to physically lock the various gears to the shaft, ensuring they cannot spin freely and that 100% of the torque from the FAW Upper Right Centre Shaft Assembly Of The Main Box is transferred.

The following table provides the complete, detailed breakdown of all 16 components identified in the ‘Main Box Upper Right Centre Shaft Assembly’ diagram for the FAW CA4251P66K24T1A3E5 tractor. Esse FAW Upper Right Centre Shaft Assembly Of The Main Box is a key to the transmission’s torque capacity.

| Mark | Parte não. | Nome da peça | Quantidade |

|---|---|---|---|

| 1 | CQ1511235S | Hex head bolt | 1 |

| 2 | 1701233-A9P | Baffle-countershaft rear bearing | 1 |

| 3 | 1701215-A2V-C00 | Cylindrical roller bearing | 1 |

| 4 | 1701211-A9P | Countershaft | 1 |

| 5 | 1701226-A7G | Woodruff key | 1 |

| 6 | Q5280510 | Spring dowel pin | 1 |

| 7 | 1701228-A7G | Flat key | 1 |

| 8 | 1701212-A9K | 3rd gear-countershaft | 1 |

| 9 | 1701213-A9K | 4th gear-countershaft | 1 |

| 10 | 1701214-A9K | 5th gear-countershaft | 1 |

| 11 | 1701247-A7K | Espaçador | 1 |

| 12 | 1701217-A7G | Reduction gear-countershaft | 1 |

| 13 | 1701229-A7G | Circlip-reduction gear | 1 |

| 14 | 1701205-A2V-C00 | Cylindrical roller bearing with stop ring | 1 |

| 15 | 1701233-A7G | Baffle-countershaft front bearing | 1 |

| 16 | CQ1511645S | Hex head bolt | 1 |

The specifications for the FAW Upper Right Centre Shaft Assembly Of The Main Box are defined by its function as the core, torque-handling gear cluster of the transmission. The entire FAW Upper Right Centre Shaft Assembly Of The Main Box is a precision-balanced and matched set.

| Vehicle Application | FAW Jiefang CA4251P66K24T1A3E5 6×4 Tractor |

| Component Group | FAW Upper Right Centre Shaft Assembly Of The Main Box |

| Common Name | Countershaft Assembly / Eixo intermediário (Upper Right) |

| Transmission Design | Twin-Countershaft Main Box (This part is one of the two shafts) |

| Main Shaft P/N | 1701211-A9P |

| Gear Set | 3rd (A9K), 4th (A9K), 5th (A9K), Reduction (A7G) |

| Gear Type | Constant-Mesh, Helical-Cut |

| Front Bearing P/N | 1701205-A2V-C00 (Roller Bearing w/ Stop Ring) |

| Rear Bearing P/N | 1701215-A2V-C00 (Cylindrical Roller Bearing) |

| Primary Function | To receive input torque and create multiple gear ratios by driving the main shaft gears. |

FAW parts, including the Cylinder Block Assembly, are packaged with care to ensure safe delivery. Each component is secured in protective materials to prevent damage during transit. The logistics network guarantees timely shipments worldwide, supporting efficient maintenance operations. Below is an image illustrating the standard packaging for FAW truck parts, showcasing the attention to detail in handling and storage.

This packaging approach minimizes the risk of corrosion or impact damage, ensuring that parts like the FAW Cylinder Block Assembly arrive in perfect condition. Customers can rely on FAW’s logistics for consistent quality and reliability.