Welcome to this critical technical guide on the FAW Step Light (Assembly 567). This is the complete, integrated “courtesy” and “safety” lighting assembly for the cab entry steps of the FAW Jiefang CA4251P66K24T1A3E5 6×4 diesel semi-trailer tractor. This is a small but essential component for driver safety and convenience.

The FAW Step Light is a “logic” system with one primary function: to provide bright, downward-facing illumination on the truck’s cab steps. Its “logic” is tied to the ‘Door Open Alarm Light Logic Assembly’ (Assembly 563), activating instantly when the door is opened. This provides a safe, visible path for the driver when entering or exiting the tall cab at night.

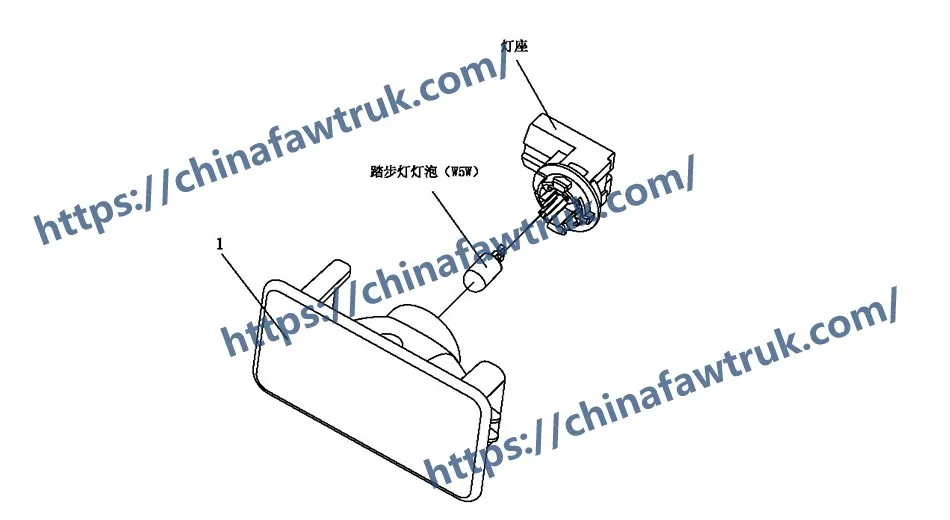

This in-depth guide is an essential resource for professional technicians and fleet safety managers. We will deconstruct the entire FAW Step Light assembly into its 2 serviceable components as listed: the main ‘Step light assembly’ (3714080-A01) and its fasteners. A non-functional FAW Step Light is a significant safety hazard, increasing the risk of slips and falls, which are a leading cause of driver injury.

The heart of the FAW Step Light system is the ‘Step light assembly’ (3714080-A01). The parts list calls for two of these, one for the driver’s side and one for the passenger’s side. This component is a sealed, integrated lamp unit specifically designed to be mounted in the “kick-panel” or “step-well” area of the cab.

**Construction:** This unit is a “logic” assembly. It consists of a durable, high-impact polycarbonate lens (typically clear or frosted) that is hermetically sealed to a robust ABS or polymer housing. This sealing is critical. The FAW Step Light is located in the “splash zone” of the door opening, where it is constantly exposed to rain, snow, mud, and road salt kicked up by the front wheels. A failed seal will allow moisture to enter, corroding the bulb’s contacts, fogging the lens, and causing an electrical short.

**Illumination “Logic”:** The light source for the FAW Step Light is almost certainly a **high-intensity, wide-angle LED (Light Emitting Diode)**. This “logic” is a critical choice for several reasons:

The FAW Step Light is part of a simple but highly effective electrical “logic” circuit that provides automated safety lighting. It is not a light that the driver manually switches on or off.

**1. The Trigger:** The “logic” for the FAW Step Light comes from the “plunger switch” (a separate component, not listed here) located in the door jamb or latch mechanism.

**2. The Action:** When this circuit closes, it sends a signal to the truck’s **Body Control Module (BCM)**. The BCM then “logically” activates the entire “courtesy light” circuit, which includes:

**3. The Purpose (Safety):** The “logic” of this system is to provide a “puddle” of light on the ground and on the steps *before* the driver’s foot leaves the cab. At night, in an unlit yard, it is impossible to see if the ground is covered in ice, oil, or debris. This FAW Step Light illuminates this “hazard zone,” preventing the slips, trips, and falls that are the most common source of driver injury.

A non-functional FAW Step Light is not just an inconvenience; it is a major safety liability for any fleet. It is a “logic” system designed to protect the driver, and its function is essential for safe operation in all conditions. The entire FAW Step Light assembly is designed around this single, critical “logic” of automatic, door-activated safety illumination.

The second component of the FAW Step Light assembly is the hardware that mounts it: the ‘Cross recessed pan head self-tapping screw’ (CQ2714816). The parts list calls for four of these, which is a pair of screws for each of the two ‘Step light assembly’ units.

This fastener is a key part of the installation “logic” for the FAW Step Light.

**1. Self-Tapping “Logic”:** The “self-tapping” (自攻螺钉) design is a critical manufacturing and service feature. These screws are designed to be driven directly into an unthreaded hole in the truck’s “kick-panel” or the plastic/metal structure of the step-well. The screw’s hardened threads cut (or “tap”) their own mating threads as they are installed. This “logic” creates an extremely tight, precise, and vibration-resistant fit without requiring a separate nut or pre-threaded boss, which would be impossible to access.

**2. Pan Head “Logic”:** The “pan head” (盘头) design is also a specific “logic” choice. This type of screw head is flat on the bottom with a wide diameter. When tightened, it distributes the clamping force over a wide area of the FAW Step Light‘s plastic mounting flange. A “countersunk” (tapered) screw would act as a wedge and instantly crack the plastic housing. This “pan head” logic prevents stress fractures and ensures the lamp is held *snug* against the cab body, preventing any “buzzes” or “rattles” from the FAW Step Light while the truck is in motion.

The following table provides the complete, detailed breakdown of all 2 component types (totaling 6 pieces) identified in the ‘Step Light’ (567) diagram for the FAW CA4251P66K24T1A3E5 tractor.

| Mark | Part No. | Part Name | Quantity |

|---|---|---|---|

| 1 | 3714080-A01 | Step light assembly | 2 |

| 2 | CQ2714816 | Cross recessed pan head self-tapping screw | 4 |

The specifications for the FAW Step Light are defined by its function as a safety-critical, automatic “courtesy” light. The FAW Step Light is an essential part of the cab’s safety and convenience logic.

| Vehicle Application | FAW Jiefang CA4251P66K24T1A3E5 6×4 Tractor |

| Component Group | FAW Step Light (Logic Assembly) |

| Main Lamp P/N | 3714080-A01 |

| Total Lamp Quantity | 2 |

| Common Name | Stepwell Light / Courtesy Light / Puddle Lamp |

| System Voltage | 24V DC |

| Light Source (Typical) | LED (Low-power, High-vibration resistance) |

| Control Logic | Automatic (Activated by BCM via door plunger switch) |

| Mounting Hardware | 4x ‘Cross recessed pan head self-tapping screw’ (CQ2714816) |

| Primary Function | To illuminate the cab steps and ground area when a door is opened, preventing slips and falls. |

FAW parts, including the Cylinder Block Assembly, are packaged with care to ensure safe delivery. Each component is secured in protective materials to prevent damage during transit. The logistics network guarantees timely shipments worldwide, supporting efficient maintenance operations. Below is an image illustrating the standard packaging for FAW truck parts, showcasing the attention to detail in handling and storage.

This packaging approach minimizes the risk of corrosion or impact damage, ensuring that parts like the FAW Cylinder Block Assembly arrive in perfect condition. Customers can rely on FAW’s logistics for consistent quality and reliability.